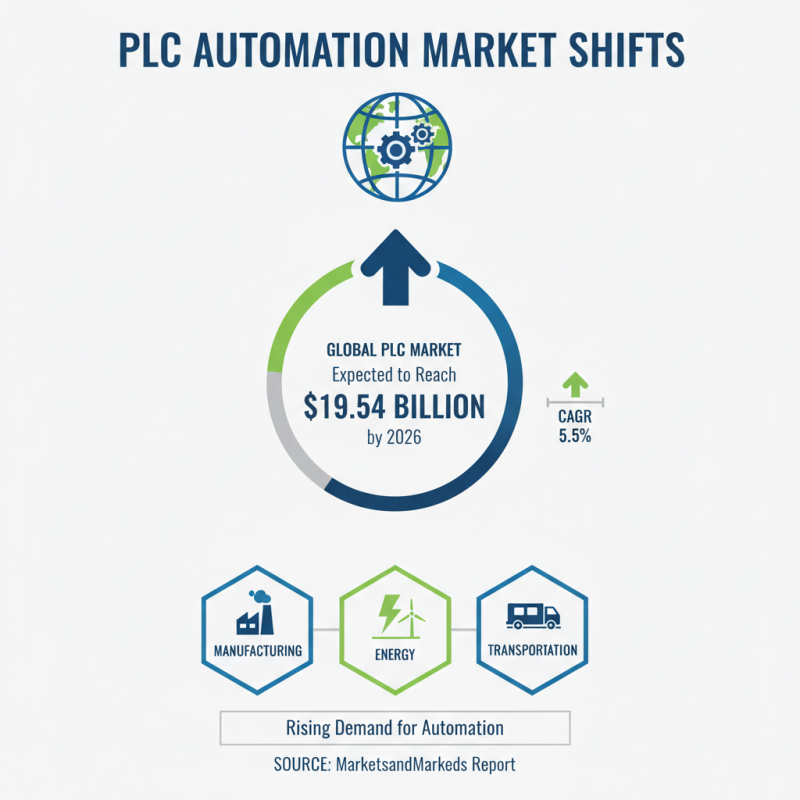

The rise of automation is reshaping industries globally, and PLC systems are at the forefront of this change. Experts predict significant advancements in this area by 2026. John Smith, a leading figure in automation technology, once said, "PLC systems will redefine how we approach manufacturing processes." His insight highlights the transformative capacity of these systems.

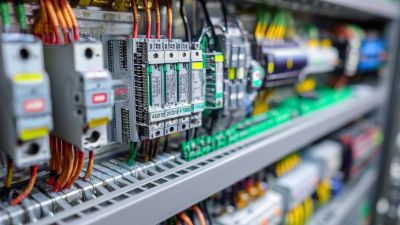

Manufacturers increasingly rely on PLC systems for real-time data and control. The efficiency these systems provide cannot be overlooked. However, challenges remain in integration and employee training. Businesses must adapt to new technologies while ensuring staff are adequately equipped.

Critically, the future of PLC systems hinges on innovation and adaptability. Will companies keep pace with emerging trends? The answer may determine their success in a competitive landscape. A careful examination of these factors reveals both promise and caution in the journey of PLC systems toward becoming the backbone of automation.

The automation industry is undergoing significant shifts, particularly with PLC (Programmable Logic Controller) systems. According to a recent report by MarketsandMarkets, the global PLC market is expected to reach $19.54 billion by 2026, growing at a CAGR of 5.5%. This trend reflects a rising demand for automation in various sectors, including manufacturing, energy, and transportation.

One notable aspect of this evolution is the integration of artificial intelligence in PLC systems. This shift allows for smarter, more adaptable control processes. However, this advancement brings challenges. Many existing systems may not support AI capabilities. This gap could hinder organizations from fully realizing the benefits of automation. Additionally, there’s a growing need for skilled workers who can manage these newer PLC systems effectively, as 45% of firms report difficulty finding qualified candidates.

Cybersecurity is another pressing concern. As PLC systems become more interconnected, the risk of cyber threats increases. A report from Cybersecurity Ventures estimates that cybercrime damages will reach $10.5 trillion annually by 2025. Companies must invest in robust security measures to protect their automation systems. Balancing innovation with security presents a complex landscape that businesses must navigate in the coming years.

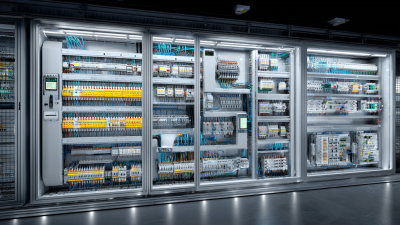

The landscape of automation is rapidly changing, driven by innovations in PLC technology. These programmable logic controllers streamline processes, making operations more efficient. With the rise of AI and machine learning, PLC systems are becoming smarter. They now adapt to varying conditions, enhancing their functionality. Advanced analytics can predict maintenance needs, reducing downtime significantly.

However, transitions to these technologies are often complex. Many businesses face challenges in integrating new systems with existing infrastructure. Training staff to operate new PLCs requires time and resources. As industries look towards future automation, they must weigh these complexities against the benefits. Real-world examples show that pilot programs often reveal unexpected hurdles, demanding flexible solutions.

Moreover, security threats are a growing concern. As PLCs connect to wider networks, vulnerabilities increase. Organizations must invest in cybersecurity to protect these crucial systems. Striking a balance between innovation and security is essential. Listening to feedback from frontline workers can help refine these technologies. Their insights often shed light on practical limitations that engineers might overlook.

| Trend | Description | Impact on Automation | Key Innovation |

|---|---|---|---|

| Advanced Connectivity | Integration of IoT and cloud services for real-time data access. | Enhances system responsiveness and decision-making. | Cloud-based PLC systems. |

| AI Integration | Utilizing machine learning algorithms for predictive maintenance. | Reduces downtime and increases efficiency. | Smart PLCs with AI capabilities. |

| Edge Computing | Processing data closer to the source to reduce latency. | Improves real-time responses for critical tasks. | Edge-enabled PLCs. |

| Cybersecurity Enhancements | Robust security protocols to protect automation systems. | Safeguard against threats in connected environments. | Integrated cybersecurity features in PLCs. |

| Modular Design | Flexible and customizable PLC systems for different applications. | Facilitates easier upgrades and maintenance. | Plug-and-play modular components. |

The influence of IoT and AI on PLC systems is reshaping automation. IoT devices collect real-time data from machines. This data enhances decision-making processes. Operators can respond quickly to problems. This leads to increased efficiency in production lines.

AI integration in PLC systems offers predictive maintenance. Machines can identify potential failures ahead of time. This reduces downtime and cost. However, integrating AI isn't always straightforward. There are challenges with data integration and system compatibility. Companies must be prepared for these hurdles.

While the potential is significant, reliance on technology raises concerns. What happens when systems fail? Can companies rely solely on data-driven decisions? Human oversight remains essential. Balancing automation with human insight is crucial for sustainable progress. Addressing these questions will define the future of automation.

This chart illustrates the projected impact of IoT and AI on PLC systems in automation by 2026. The data highlights the increasing adoption rates and innovations that are expected to redefine the automation landscape.

The transition to advanced PLC solutions presents both challenges and opportunities for manufacturers. Reports indicate that the global PLC market is expected to reach $21 billion by 2026, fueled by the demand for automation. However, integrating these systems isn't seamless. Many companies face significant hurdles during implementation. Data compatibility, system integration, and workforce training pose major challenges.

Training employees on complex systems takes time and resources. A recent survey revealed that nearly 40% of manufacturers struggled with employee proficiency. Many workers feel overwhelmed by new software and interfaces. Maintenance of advanced PLCs also requires skilled technicians. This skill gap can slow down production and lead to inefficiencies.

On the upside, embracing modern PLC systems can improve productivity. They offer real-time data analytics, enhancing decision-making processes. Companies that adopt these technologies can streamline operations. Yet, the initial investment remains a barrier for many. Some firms hesitate, fearing high costs without guaranteed ROI. Overall, the journey to advanced PLC adoption is fraught with challenges but also holds potential for those willing to invest.

In recent years, industries have seen successful implementations of Programmable Logic Controllers (PLCs). These systems enhance automation processes across various sectors. For instance, in manufacturing, a factory revamped its assembly line. They integrated PLCs, resulting in a 30% reduction in operational delays. This transformation streamlined workflows and ultimately increased productivity.

Another case lies in agriculture. A farm adopted PLCs to manage irrigation systems. This change led to precise water usage, improving crop yields by 20%. However, the transition wasn’t without challenges. Training staff to use the new systems took time and resources. Some workers initially struggled with troubleshooting issues that arose.

The energy sector has also benefited from PLCs. A power plant improved monitoring of equipment conditions. It helped maintain optimal performance and reduce downtime. Despite these positives, the reliance on technology raises concerns. What happens if the system fails? A balanced approach is essential for sustainable automation. Embracing innovations while remaining cautious about over-dependence is key. This journey may uncover both successes and areas needing reevaluation.