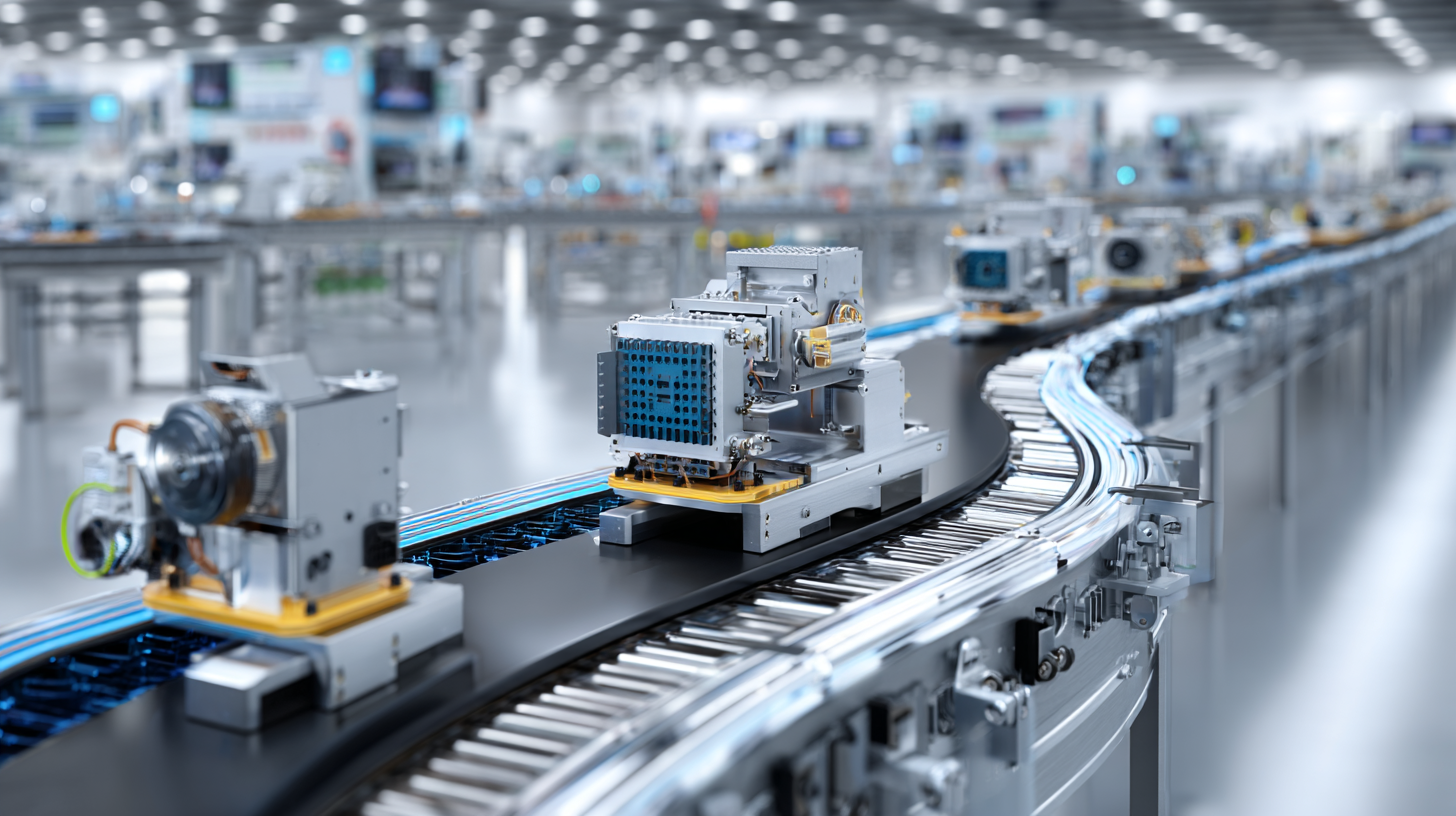

In the rapidly evolving landscape of manufacturing automation, the integration of Low Cost PLC with HMI (Human-Machine Interface) applications has become a focal point for industries striving to enhance efficiency and reduce operational costs. As manufacturers seek to streamline processes and improve control, the demand for cost-effective and user-friendly solutions is at an all-time high.

This blog aims to explore and compare various low-cost PLC options equipped with HMI capabilities, examining their functionalities, ease of use, and overall impact on production workflows. By evaluating the strengths and weaknesses of these systems, we will provide valuable insights for manufacturers looking to optimize their automation strategies while keeping a keen eye on budget constraints. Join us as we navigate through the best low-cost PLC with HMI applications that are setting new standards in the realm of manufacturing automation.

In the rapidly evolving landscape of manufacturing automation, low-cost Programmable Logic Controllers (PLCs) paired with Human-Machine Interface (HMI) applications have emerged as a game-changer for businesses seeking efficiency without compromising quality. One of the key benefits of these economical PLCs is their accessibility, allowing small and medium-sized enterprises (SMEs) to implement advanced automation solutions that were once the domain of larger corporations. Lower upfront investment reduces barriers, enabling more organizations to harness technology that enhances productivity and streamlines operations.

Another significant advantage lies in the flexibility and scalability of low-cost PLC systems. As manufacturing needs change, these PLCs provide an adaptable platform that can grow with a business. Their compatibility with various HMI applications fosters seamless interaction between operators and machines, facilitating real-time monitoring and control. This integration not only enhances operational visibility but also empowers employees to make informed decisions quickly, driving efficiency and reducing downtime. Ultimately, the combination of affordability and advanced functionality positions low-cost PLCs as a pivotal asset in the quest for smarter manufacturing solutions.

Human-Machine Interface (HMI) applications are crucial in optimizing user interaction within manufacturing automation. As industrial processes become increasingly complex, the integration of intuitive HMI solutions allows operators to efficiently control machines and respond swiftly to system changes. According to a report by MarketsandMarkets, the HMI market is anticipated to reach $5.9 billion by 2024, highlighting the growing emphasis on enhancing user interaction in automation systems.

A well-designed HMI not only improves operational efficiency but also significantly reduces the risk of human error. Data from the International Society of Automation (ISA) reveals that about 70% of all industrial accidents can be directly attributed to human error. By employing advanced HMI technologies such as touchscreens, graphical displays, and real-time data analytics, manufacturers can create a user-friendly interface that presents critical information in an easily digestible format. This shift towards user-centric design facilitates quicker decision-making and enhances overall productivity on the factory floor.

Moreover, the rise of Industry 4.0 has driven the demand for smart HMI solutions capable of integrating with IoT devices and providing remote access to systems. A joint study by Deloitte and the Manufacturing Institute emphasized that manufacturers adopting these technologies experience, on average, a 30% increase in overall equipment effectiveness (OEE). Incorporating low-cost PLCs with advanced HMI capabilities can empower manufacturers to modernize their operations, streamline workflows, and ultimately boost their bottom line.

In the realm of manufacturing automation, small to medium enterprises (SMEs) often struggle with high costs while trying to implement advanced technologies like Programmable Logic Controllers (PLCs) with Human-Machine Interfaces (HMIs). This blog highlights some of the best low-cost PLCs available that are tailored for SMEs, making automation more accessible without compromising functionality. Brands like Siemens, Allen-Bradley, and Mitsubishi offer budget-friendly options that demonstrate reliability and efficiency.

When selecting a PLC for your business, consider these tips: First, assess your specific needs regarding I/O requirements and scalability. A PLC with modular capabilities can grow with your business. Second, pay attention to compatibility with HMI systems, ensuring seamless integration for a user-friendly interface. Lastly, evaluate the support and resources available for troubleshooting and maintenance, as effective customer service can be invaluable in a high-stakes environment.

Choosing the right PLC can significantly impact productivity and operational costs. By focusing on affordable yet capable options, SMEs can leverage automation technologies to streamline processes and enhance competitiveness in the market. Remember, the goal is to find a balance between cost-effectiveness and functional merit.

In modern manufacturing automation, integrating Human-Machine Interfaces (HMIs) with Programmable Logic Controllers (PLCs) has become essential for optimizing production processes. The synergy between HMIs and PLCs allows operators to monitor and control machines more effectively, leading to enhanced efficiency and reduced downtime. By visualizing complex control systems through an intuitive HMI, operators can quickly respond to issues and make data-driven decisions.

Tips for achieving a seamless integration include ensuring compatibility between the HMI software and PLC hardware. Choosing a standardized communication protocol, such as Modbus or Ethernet/IP, can significantly ease integration efforts. Additionally, it's beneficial to invest time in training staff on the specific features of the HMI to fully leverage its capabilities.

Another important tip is to prioritize user-friendly interface design when developing HMI screens. This promotes ease of navigation and minimizes the potential for operator error. Clear labeling of buttons and real-time data visualization can improve reaction times in critical situations, ultimately supporting smoother manufacturing operations and a more productive workforce.

The manufacturing industry is increasingly adopting low-cost PLCs (Programmable Logic Controllers) integrated with HMI (Human-Machine Interfaces) to streamline processes and boost productivity. According to a recent report from Gartner, the global market for PLC systems is projected to reach $15 billion by 2025, driven largely by the demand for cost-effective automation solutions. One notable case study involves a mid-sized automotive parts manufacturer that implemented a low-cost PLC with HMI to optimize their assembly line. This transition resulted in a 20% increase in operational efficiency while significantly reducing labor costs.

Implementing such low-cost solutions can be highly beneficial but poses its challenges. It's crucial to ensure compatibility between different components of the automation system. Also, investing in robust training for employees can maximize the benefits of new technology. **Tips:** Always evaluate the total cost of ownership, not just the initial investment, to avoid hidden long-term expenses. Additionally, consider modular PLCs, which allow for gradual upgrades, minimizing disruption while scaling operations.

Another example of successful implementation is within the food processing industry, where a low-cost PLC was utilized to monitor and control temperature and humidity levels in real-time. This enabled compliance with stringent safety standards without breaking the bank. Automated systems like this have the potential to reduce waste by up to 30%, making for a much more sustainable operation. **Tips:** Look for PLC providers that offer customizable solutions suited to your specific industry needs. Leveraging cloud-based software can also enhance data analysis, leading to smarter manufacturing practices.

This chart illustrates the cost-effectiveness of various low-cost PLC solutions commonly utilized in manufacturing automation. It demonstrates the annual expenditures associated with different solutions, providing insights into their feasibility for implementation in real-world applications.