In the rapidly evolving landscape of manufacturing, the importance of effective automation cannot be overstated. PLC (Programmable Logic Controller) automation solutions play a crucial role in enhancing operational efficiency, minimizing downtime, and ensuring precise control over manufacturing processes. As industry expert Dr. John Smith, a renowned advocate for smart manufacturing, remarked, “Incorporating PLC automation into production lines is not just a trend; it is essential for remaining competitive in today's market.” This reflects a growing recognition of how PLC automation can streamline processes and improve overall productivity.

The demand for sophisticated PLC automation solutions continues to rise as companies seek to optimize their operations. By leveraging advanced technologies, businesses can achieve greater flexibility and adaptability in their manufacturing processes. The integration of PLC systems has proven to be a game-changer, allowing for real-time data monitoring and analysis, which ultimately leads to informed decision-making and enhanced performance. As we explore the ten best PLC automation solutions available today, it becomes evident that investing in these technologies is pivotal for manufacturers aiming to thrive in an increasingly complex and competitive environment.

Programmable Logic Controllers (PLCs) have revolutionized the landscape of manufacturing by providing robust automation solutions that enhance production efficiency and reliability. At the heart of PLC automation is the ability to control machinery and processes through programmable commands, allowing manufacturers to streamline operations, reduce human error, and optimize workflow. This technology has become essential in various applications, from simple tasks like controlling motors and sensors to complex process automation that integrates multiple systems and machines.

The use of PLCs in manufacturing offers numerous advantages, including real-time monitoring and control, which enables immediate adjustments to be made in response to changing conditions. This capability not only improves operational efficiency but also enhances data collection and analysis, leading to better decision-making. Additionally, PLCs support scalability, allowing manufacturers to easily adapt their automation systems to accommodate changing production demands or to integrate new technologies. With their ability to facilitate a flexible and responsive production environment, PLC automation plays a critical role in driving manufacturing innovation and competitiveness in today’s fast-paced market.

Effective PLC (Programmable Logic Controller) automation solutions are pivotal for optimizing manufacturing processes. One key feature of these solutions is their scalability, allowing businesses to expand their operations without significant disruptions. Whether a facility is small or large, a good PLC system can adapt to varying production demands, facilitating a smooth transition as the business grows. This flexibility ensures that manufacturers can implement efficient automation without the need for completely overhauling their existing systems.

Another vital aspect is the ease of integration with existing equipment and software. Modern PLC solutions are designed to work seamlessly with various machinery and industrial protocols, enabling manufacturers to enhance their operations without major investments in new hardware. Moreover, advanced data analytics capabilities provide actionable insights into production processes, allowing organizations to identify bottlenecks, optimize workflows, and make informed decisions to improve efficiency. These features collectively contribute to a streamlined manufacturing process, enhancing productivity while reducing operational costs.

This bar chart illustrates the effectiveness of various PLC automation solutions based on key features. The chart shows five essential features rated on a scale of 1 to 10, where higher scores indicate better performance in streamlining manufacturing processes.

In today's fast-paced manufacturing environment, streamlining processes through effective automation is essential for businesses seeking to enhance efficiency and reduce operational costs. PLC (Programmable Logic Controller) automation solutions have become vital tools for manufacturers aiming to achieve seamless production workflows. These systems provide robust control over machinery and processes, enabling real-time monitoring and adjustments that optimize performance and minimize downtime.

The complexity of modern manufacturing requires solutions that can easily integrate with existing systems while offering advanced data analytics and reporting capabilities. Top PLC automation solutions not only automate routine tasks but also facilitate better communication between equipment and operators, enhancing decision-making and productivity. By implementing the right PLC automation system, manufacturers can achieve a higher level of precision in their operations, reduce human error, and improve overall safety standards on the shop floor. As industries continue to evolve, these innovative automation solutions stand at the forefront of manufacturing advancement, promising to revolutionize how processes are managed and executed.

| Solution Name | Features | Integration Capability | User-Friendliness | Scalability | Estimated Cost |

|---|---|---|---|---|---|

| Solution A | Real-time monitoring, data analytics | High with cloud services | Very user-friendly | Highly scalable | $$$ |

| Solution B | Remote access, customizable dashboards | Medium with existing software | Moderately user-friendly | Moderately scalable | $$ |

| Solution C | Predictive maintenance, alerts | High with IoT | Very user-friendly | Highly scalable | $$$$ |

| Solution D | Workflow automation, reporting tools | Medium integration | Easy to use | Moderately scalable | $$$ |

| Solution E | Machine learning insights, optimization | High integration | User-friendly for tech-savvy | Highly scalable | $$$$$ |

| Solution F | Data visualization, user analytics | Medium integration capability | User-friendly | Moderately scalable | $$ |

| Solution G | Robotic process automation, simulation | High with robotics | Moderately user-friendly | Highly scalable | $$$$ |

| Solution H | Cloud-based services, collaboration tools | High with cloud | Very user-friendly | Highly scalable | $$$$$ |

| Solution I | Compliance tracking, security features | Medium integration | Moderately user-friendly | Moderately scalable | $$ |

| Solution J | Asset management, task prioritization | High with ERP systems | User-friendly | Highly scalable | $$$$ |

When considering PLC automation solutions, conducting a comparative analysis of available tools is essential for optimizing manufacturing processes. Various PLC software and hardware options provide distinct features that can cater to specific operational needs. Key factors such as scalability, ease of integration, user interface design, and support services play a critical role in determining the best fit for a manufacturing environment. By evaluating these aspects, companies can effectively streamline their operations and improve productivity.

Moreover, the compatibility of PLC systems with existing equipment and software can significantly influence the overall efficiency of manufacturing processes. It's crucial for businesses to assess how well a PLC solution can interface with their current technology stack. Additional considerations include the level of customization offered by the automation tools and the availability of advanced analytics capabilities. These features empower manufacturers to harness real-time data for informed decision-making, enhancing flexibility and responsiveness in production workflows. Ultimately, a thorough analysis can guide organizations in selecting a PLC automation tool that not only meets immediate operational demands but also supports future growth.

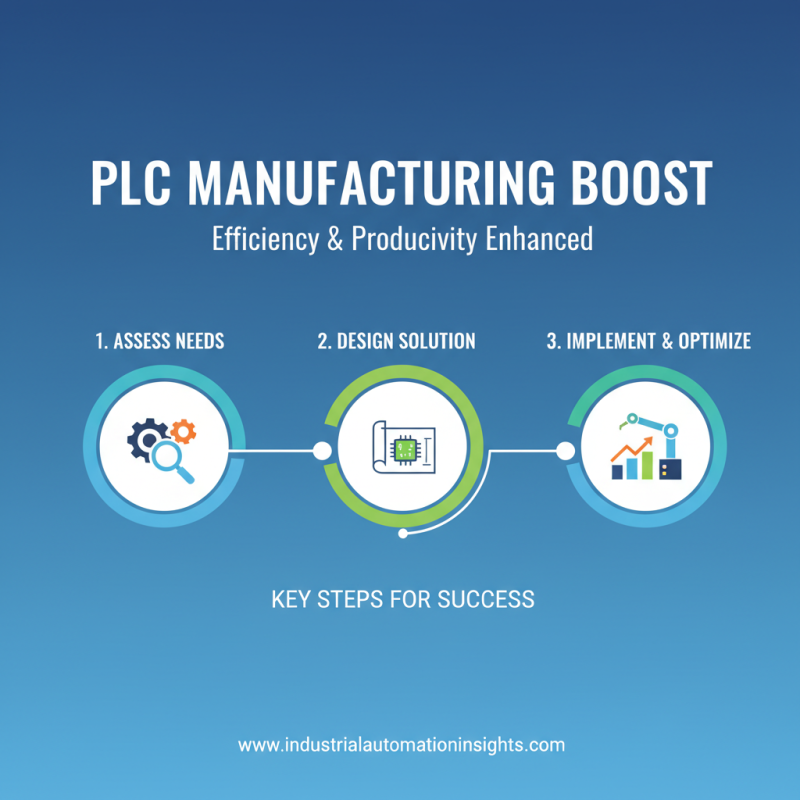

Implementing PLC (Programmable Logic Controller) solutions in manufacturing can significantly enhance efficiency and productivity. A successful implementation strategy begins with a clear understanding of your specific automation needs. Conducting a thorough assessment of your current manufacturing processes will help identify areas that require improvement. This initial step ensures that the chosen PLC solution aligns well with your operational goals.

Once you have selected a PLC solution, focus on proper training for your staff. Ensure that they understand the system's functionalities and how to troubleshoot common issues. Providing hands-on training and creating user manuals tailored to your operations can bridge any knowledge gaps. Well-trained personnel can maximize the benefits of automation, minimizing downtime and promoting a smoother transition.

Tips: Always consider scalability when implementing PLC solutions. As your manufacturing process evolves, your automation needs may change; thus, selecting a system that can expand with your operations is essential. Regularly schedule maintenance checks to ensure that the PLC system operates at peak performance and address any potential issues before they disrupt your production line.