In today's rapidly advancing industrial landscape, the demand for more efficient and reliable automation solutions has never been greater. A Distributed Control System (DCS) stands out as a pivotal technology in meeting these demands, enabling industries to improve operational efficiency, safety, and scalability. According to a report by MarketsandMarkets, the global DCS market is projected to grow from USD 18.3 billion in 2020 to USD 25.0 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.4%. This growth is driven by the increasing need for automation across various sectors, including oil and gas, power generation, and pharmaceuticals.

A Distributed Control System offers a decentralized approach that enhances process management by distributing control elements across the network. This architecture not only minimizes downtime but also allows for real-time monitoring and control, which is crucial for modern manufacturing processes. In fact, the International Society of Automation (ISA) notes that DCS implementations can lead to up to a 30% reduction in operating costs due to increased system reliability and efficiency. As industries navigate the complexities of digital transformation and smart manufacturing, the strategic implementation of a Distributed Control System becomes increasingly essential for achieving operational excellence and maintaining a competitive edge.

Distributed Control Systems (DCS) play a crucial role in enhancing industrial automation, offering several key benefits that streamline operations and improve efficiency. One of the primary advantages of a DCS is its ability to provide centralized monitoring while decentralizing control functions across various units. This structure allows for improved response times to changes in processes, as local teams can make swift adjustments based on real-time data without waiting for directives from a centralized location. Additionally, the division of control minimizes the risk of a single point of failure, thereby enhancing system reliability and stability in industrial environments.

Another significant benefit of DCS in industrial automation is their integrated approach to data management and analysis. By collecting data from multiple sensors and devices across the production line, a DCS enables operators to gain comprehensive insights into system performance. These insights can be leveraged to optimize processes, enhance productivity, and predict maintenance needs before issues arise. Consequently, this leads to lower operational costs and a more efficient use of resources, which is essential for maintaining a competitive edge in today’s fast-paced industrial landscape.

| Benefit | Description | Example Applications | Impact on Efficiency |

|---|---|---|---|

| Scalability | Easily add or remove control nodes to adjust to changing needs. | Oil Refining, Power Generation | Increases ability to expand operations without significant overhaul. |

| Reliability | Redundant systems reduce risk of total system failure. | Chemical Processing, Water Treatment | Improves uptime and reduces maintenance costs. |

| Flexibility | Supports various control strategies and communication protocols. | Manufacturing, Pharmaceuticals | Enhances productivity by adapting to different processes. |

| Integration | Seamlessly integrates with existing systems and devices. | Automotive, Food & Beverage | Streamlines operations and data flow across platforms. |

| Improved Monitoring | Real-time data allows for better decision-making. | Energy Management, HVAC Systems | Enhances performance by enabling proactive maintenance. |

A Distributed Control System (DCS) is integral to modern industrial automation, providing a decentralized approach to process control and monitoring. One of the key components of a DCS is its networked architecture, which allows various control elements to communicate and coordinate with each other seamlessly. This architecture typically consists of controllers, sensors, and actuators strategically placed throughout the facility. Each controller manages specific processes or equipment, enabling localized decision-making and faster response times, which ultimately enhances operational efficiency.

Another critical component is the Human-Machine Interface (HMI), which serves as the interaction point between operators and the control system. The HMI displays real-time data and provides visualizations of the processes, making it easier for operators to monitor and manage operations. Additionally, data historians collect and archive operational data for analysis and reporting, supporting insights into performance optimization and predictive maintenance. Together, these components create a robust and responsive control environment that not only improves production reliability but also supports scalability as industrial needs evolve.

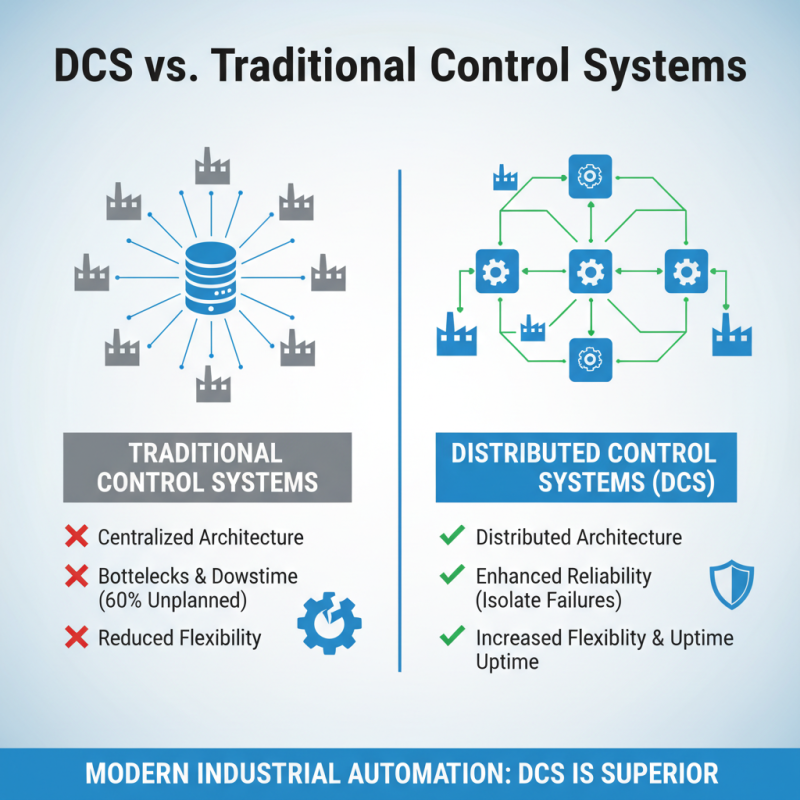

When assessing the choices between Distributed Control Systems (DCS) and traditional control systems, several key factors illustrate why DCS may be the superior option for modern industrial automation. Traditional control systems often rely on centralized architectures, which can lead to bottlenecks, increased downtime, and reduced flexibility. A report from the International Society of Automation (ISA) indicates that over 60% of unplanned downtime in industrial environments is due to system failures, a concern that DCS architectures address through their distributed nature. By distributing control functions across multiple nodes, DCS enhances reliability and allows for more seamless operation, as malfunctioning components can be isolated without halting entire processes.

Moreover, DCS systems offer improved scalability and adaptability compared to their traditional counterparts. According to a 2022 analysis by MarketsandMarkets, the global DCS market is projected to grow from $19.0 billion in 2020 to $27.2 billion by 2025, reflecting a growing preference for systems that can efficiently accommodate varying production demands. DCS provides a modular approach that supports easy integration of new components and technologies as industries evolve, minimizing the need for extensive system overhauls. This adaptability is essential for businesses looking to stay competitive in an ever-changing market landscape, highlighting the advantages of opting for a Distributed Control System over more rigid traditional systems.

In today’s rapidly evolving industrial landscape, scalability and flexibility are paramount when selecting a distributed control system (DCS) for automation needs. A DCS offers an adaptable architecture that can easily expand to handle increasing production demands or incorporate new technologies. This adaptability is crucial for enterprises aiming to enhance their operational efficiency without the need for a complete system overhaul. As industries grow or shift focus, the ability to seamlessly integrate additional control nodes or modules ensures that businesses can respond effectively to market changes.

Flexibility in design is another hallmark of a distributed control system. Unlike traditional centralized approaches, a DCS allows for localized control of processes, which minimizes the risk of single points of failure. This decentralized structure not only enhances reliability but also promotes tailored solutions that can meet specific operational requirements. Furthermore, the modular nature of DCS allows for incremental improvements, enabling manufacturers to adopt new features or upgrade components as needed. This ensures that the system evolves alongside technological advancements and business goals, thereby fostering innovation within industrial operations.

Distributed Control Systems (DCS) have proven invaluable across various industries, notably in refining, petrochemicals, and power generation. According to a report from Research and Markets, the global DCS market was valued at approximately $19 billion in 2021 and is expected to grow at a CAGR of 6% from 2022 to 2029. This growth is driven by the increasing need for automation and control solutions that enhance operational efficiency and safety in complex industrial environments.

In the oil and gas sector, DCS plays a critical role in managing large-scale facilities, providing real-time data and advanced analytics to optimize production processes. For instance, a DCS can help to monitor multiple remote locations, enabling operators to make informed decisions promptly, which can increase productivity by up to 15%. Similarly, in power generation, these systems help maintain grid stability and reliability by managing the interdependence of various energy sources, thus contributing to greater sustainability.

**Tip**: When selecting a DCS, consider the scalability of the system to accommodate future expansions and advancements in technology. Ensuring that your system can adapt to your evolving needs will help maximize your investment.

In the pharmaceutical industry, a well-implemented DCS can significantly reduce production downtimes and ensure compliance with stringent regulatory standards. Data from the International Society for Pharmaceutical Engineering highlights that companies using DCS have reported a 30% reduction in errors during the manufacturing process, leading to improved product quality and safety. By integrating process automation and digital solutions, DCS not only enhances operational throughput but also supports continuous compliance with industry best practices.

**Tip**: Always prioritize user training and support for DCS implementations. Investing in operator training can lead to greater system utilization and fewer operational mishaps, ultimately impacting your bottom line positively.