In today's industrial landscape, choosing the right Dcs Control System is crucial for operational efficiency. According to a report by MarketsandMarkets, the global DCS market is projected to reach $22 billion by 2025, driven by increased automation needs. This underscores the importance of selecting a system that aligns with your specific industry requirements.

Expert Andrew Collins states, "The right Dcs Control System can enhance productivity and reduce operational risks." However, many organizations still grapple with identifying the best fit for their applications. This challenge can lead to costly mistakes, underscoring the need for a thoughtful approach to decision-making.

Factors like scalability, compatibility, and user experience should be considered. Each industry has unique demands that influence the choice of a Dcs Control System. A misstep in this process can impact not just efficiency but also safety and compliance. Ultimately, understanding your precise needs and the features of available systems is essential for success.

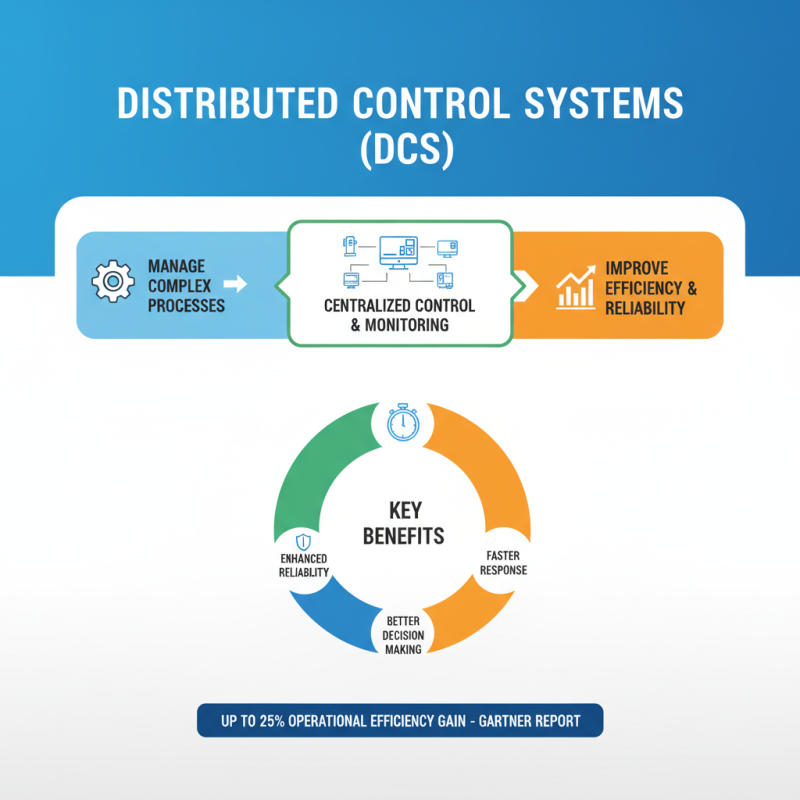

DCS (Distributed Control Systems) are crucial in various industries. They manage complex processes efficiently. Understanding their basics helps in choosing the right system for specific needs. A DCS allows for centralized control and monitoring of equipment, improving reliability and response times. For example, a report by Gartner indicates that DCS can enhance operational efficiency by up to 25%.

There are several key functions of DCS. They enable real-time data collection and analysis, which support better decision-making. For instance, temperature and pressure readings can be monitored continuously. This helps identify risks early. However, integrating new systems can be challenging. Existing infrastructure may limit compatibility with new DCS technologies.

User interfaces play a significant role in DCS effectiveness. They should be intuitive and easy to navigate. A complex interface can lead to errors. Additionally, training operators is vital. Without proper training, users may not fully leverage the system’s capabilities. Ultimately, the right DCS choice balances functionality and usability, meeting unique industry demands.

Choosing the right Distributed Control System (DCS) is crucial for your industry. One of the key factors to consider is scalability. A study by the International Society of Automation reports that over 60% of companies face challenges when expanding their control systems. This limitation can hinder growth. Daily operations may suffer if your system cannot adapt to increased demand.

Another factor is user-friendliness. Complex systems often lead to a steep learning curve. According to a recent survey, 40% of operators stated difficulty in navigating their DCS interfaces. This can result in wasted time and potential errors. Simple, intuitive designs enhance efficiency. Systems should allow quick adjustments without extensive training.

Integration capabilities matter as well. The ability to connect with existing systems can make a difference. Research shows that 50% of organizations experience issues when trying to integrate new DCS with legacy systems. This can lead to data silos and inconsistencies. Consider systems that offer seamless interoperability to avoid these pitfalls.

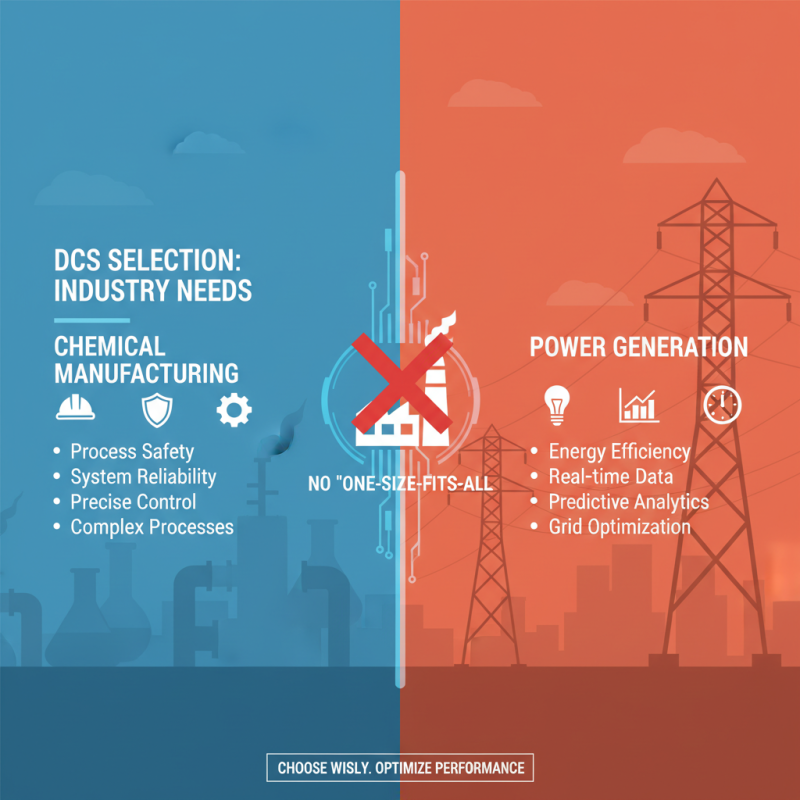

Choosing the right Distributed Control System (DCS) for your industry requires careful consideration. Each sector has unique needs. For instance, a chemical manufacturing facility may prioritize process safety and reliability. It needs precise control over complex processes. In contrast, the power generation industry may focus more on energy efficiency and real-time data analysis. This divergence indicates that one-size-fits-all solutions often fall short.

Understanding these specific requirements is crucial. Industries like food and beverage demand strict compliance with hygiene standards. Their DCS must track and control various parameters like temperature and pressure accurately. On the other hand, oil and gas operations often require robust systems that can withstand harsh environments. Reflecting on these differences can help in making informed choices.

Sometimes, organizations overlook the importance of scalability. They may invest in a system that meets current needs but fails to support future growth. Upgrading systems later can result in significant disruption. This reality emphasizes the need for foresight in selecting a DCS. Every industry has its complexities, and addressing them from the outset saves time and resources.

When selecting a DCS control system, performance metrics are crucial. They determine how well the system responds to process changes. According to a recent industry report, optimal responsiveness improves operational efficiency by up to 25%. Systems with faster processing times enhance real-time data analysis, leading to better decision-making.

Reliability data is equally important. A comparative study shows that systems with an uptime of 99.9% ensure continuous operation. This significantly reduces production losses. However, some systems may overpromise reliability, leading to underperformance. Users must scrutinize maintenance records and failure rates before making a decision.

Consider the deployment environment when evaluating systems. Harsh conditions can affect performance. Even robust systems can falter without proper installation. It's essential to reflect on how the chosen DCS aligns with industry requirements. Not all systems will meet the specific needs of every operation. Balancing features, costs, and reliability is a complex task that demands careful analysis.

When selecting a Distributed Control System (DCS), vendor support is crucial. A responsive and knowledgeable vendor can make a significant difference. They should offer comprehensive training to your staff. This ensures effective use of the system over time. Fast support can minimize downtime, which is vital in production environments. Look for vendors who provide on-site assistance as well as remote support options.

Consider the lifecycle management of the DCS. The industry's needs can change quickly. It is essential that the vendor can update and maintain the system as required. Regular updates keep the system secure and efficient. A flexible upgrade path is a strong indicator of a good vendor. Some vendors promise support but may fail to meet expectations in critical situations. This creates unnecessary stress.

Evaluate how long the vendor has been in the market. Experience often translates to better knowledge of industry-specific challenges. Ask for case studies or testimonials from similar industries. Learning from others' experiences can guide your decision. Ultimately, choosing a DCS is not just about the technology. It involves a partnership that should enhance your operational capacity.

| Criteria | Evaluation Metric | Importance Level | Vendor Support Quality | Lifecycle Management |

|---|---|---|---|---|

| System Compatibility | Integration with existing systems | High | 24/7 Technical Support | Regular software updates |

| Scalability | Ability to expand system functionality | Medium | Good training resources | Comprehensive transition plans |

| User Interface | Ease of use and navigation | High | Responsive customer service | Documentation availability |

| Cost of Ownership | Initial purchase and operational costs | High | Transparent pricing model | Cost-effective upgrade paths |

| Reliability | System uptime and fault tolerance | High | Proactive maintenance services | Predictive analytics tools |