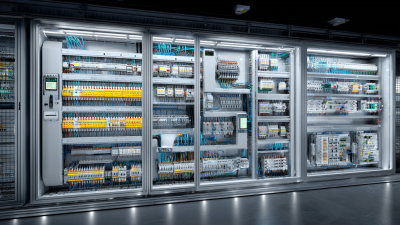

In the rapidly evolving landscape of industrial automation, the choice of a suitable PLC system has significant implications for cost efficiency and operational effectiveness. According to the International Society of Automation, an increasing number of manufacturers are leveraging PLC systems to enhance productivity, with studies indicating that optimizing automation frameworks can lead to up to a 30% reduction in downtime and a 20% increase in throughput. Various types of PLC systems—ranging from compact to modular and advanced industrial PCs—offer unique benefits and cost structures that can cater to different industrial applications. Understanding these distinctions is crucial for decision-makers aiming to maximize their return on investment in automation technologies. As companies continue to navigate the complexities of production processes, a well-informed comparison of PLC system types will illuminate the path toward more efficient and effective operational strategies.

When considering the cost efficiency of different types of PLC systems in industrial automation, it's important to analyze the unique features and capabilities each system offers. The global automation market is projected to reach a staggering USD 407.4 billion by 2032, expanding at a CAGR of 8.2%. This growth highlights the increasing demand for advanced automation solutions, including varied PLC technologies that cater to specific operational needs.

Compact PLCs, often designed for basic automation tasks, offer a cost-effective solution for smaller operations. Their simplicity and efficiency not only streamline processes but also cut down on initial investments and maintenance costs. Conversely, more sophisticated systems provide enhanced performance and scalability, making them suitable for complex industrial environments. By comparing these systems, businesses can assess their requirements and determine which type of PLC offers the best return on investment, ultimately enhancing their automation strategy while keeping costs in check.

In today's competitive manufacturing landscape, understanding the Total Cost of Ownership (TCO) for different PLC (Programmable Logic Controller) types is essential for optimizing investment in industrial automation. TCO not only includes the initial purchase price but also encompasses installation, maintenance, training, and potential downtime costs over the PLC's lifecycle. According to a report by ARC Advisory Group, the operational costs associated with PLCs can represent up to 75% of the total cost over time, making it crucial to choose wisely.

When evaluating PLC system types, it’s important to consider factors such as specific application requirements, scalability, and manufacturer support. For instance, a compact and modular PLC may offer lower initial costs, but the long-term reliability and support from the manufacturer can significantly influence maintenance costs. The right choice can lead to a reduction of up to 30% in operational expenses across a manufacturing facility.

**Tip:** Always factor in not just the purchase price but also the potential for improved productivity and efficiency offered by advanced PLC systems. Investing in higher-quality, feature-rich PLCs is often justified by lower operational costs and increased uptime.

**Tip:** Regular training for personnel can lead to better system utilization, reducing errors and enhancing productivity, effectively minimizing the TCO associated with PLCs.

This chart illustrates the total cost of ownership for various types of PLC systems used in manufacturing, highlighting their initial costs, maintenance costs, and operational efficiencies.

When considering industrial automation, evaluating the Return on Investment (ROI) for various PLC (Programmable Logic Controller) solutions becomes crucial for businesses aiming to enhance both efficiency and profitability. Each type of PLC system—ranging from compact designs suitable for smaller projects to complex, modular units for extensive operations—offers unique cost structures and operational advantages. For instance, while a more sophisticated PLC may entail higher initial costs, its advanced capabilities can lead to substantial savings in time and resource management, justifying the investment through improved productivity.

Moreover, understanding the long-term benefits of implementing a specific PLC solution is key to calculating its true ROI. Factors such as reduced downtime, increased energy efficiency, and the ability to easily integrate with existing systems play significant roles in shaping overall cost efficiency. Additionally, considering how different PLC types contribute to scalability can impact future expenditures, making it vital for companies to align their automation goals with an appropriate PLC technology. Therefore, conducting a thorough analysis of ROI not only aids in selecting the right PLC system but also ensures that businesses can adapt and thrive in a competitive industrial landscape.

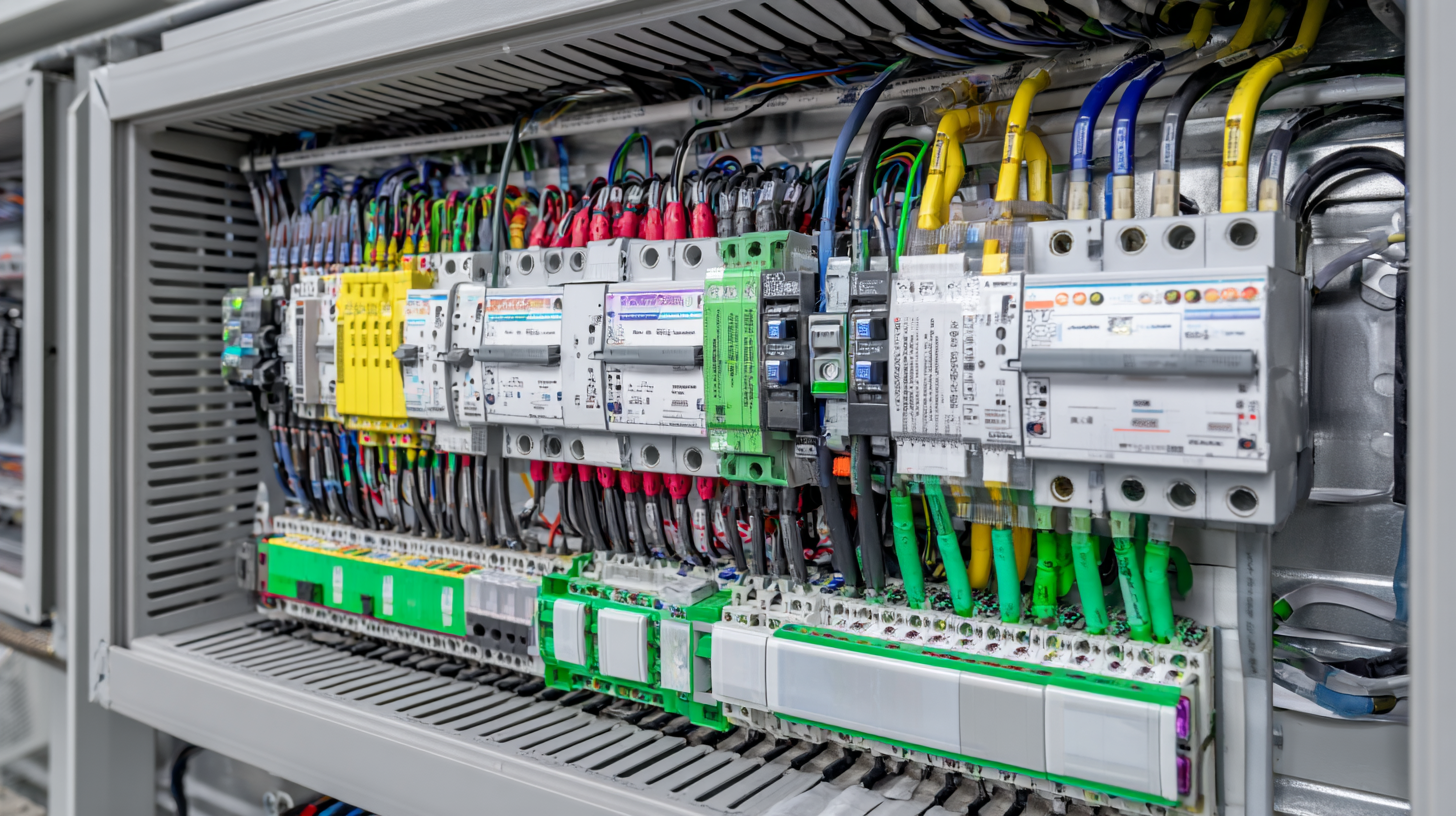

When selecting a Programmable Logic Controller (PLC) system for industrial automation, several key factors significantly influence cost savings. One of the primary considerations is the system's scalability. A scalable PLC allows businesses to expand their operations without the need for a complete overhaul, thereby reducing future investment costs. In addition, using modular components can further enhance flexibility and minimize expenses when additional functionalities are required.

Another critical aspect is the ease of integration with existing systems. Choosing a PLC that seamlessly interfaces with legacy machinery and software can save significant time and money during implementation. This compatibility not only accelerates the installation process but also avoids the potential costs associated with extensive retraining of staff or modification of processes. Moreover, energy efficiency plays a vital role in long-term savings; selecting PLC systems designed for low power consumption can lead to reduced operational costs over time. By focusing on these influential factors, industries can optimize their PLC selection process and achieve greater cost efficiency in their automation strategies.

In the realm of industrial automation, the implementation of cost-effective PLC (Programmable Logic Controller) solutions can significantly enhance operational efficiency and reduce overall costs. A recent report by MarketsandMarkets highlights that the global PLC market is expected to reach $12.14 billion by 2026, with a compound annual growth rate (CAGR) of 6.73% from 2021. This growth is driven by the need for advanced automation and IoT integration, which in turn fosters innovation in PLC technologies.

In the realm of industrial automation, the implementation of cost-effective PLC (Programmable Logic Controller) solutions can significantly enhance operational efficiency and reduce overall costs. A recent report by MarketsandMarkets highlights that the global PLC market is expected to reach $12.14 billion by 2026, with a compound annual growth rate (CAGR) of 6.73% from 2021. This growth is driven by the need for advanced automation and IoT integration, which in turn fosters innovation in PLC technologies.

Case studies illustrate how various companies have successfully implemented cost-effective PLC systems to streamline their operations. For instance, a leading automotive manufacturer utilized modular PLCs to synchronize multiple production lines, achieving a reported 30% reduction in downtime and a 15% increase in throughput. Similarly, a food processing firm adopted a distributed PLC architecture, leading to a 20% savings in labor costs by automating repetitive tasks. These examples underscore the tangible financial benefits and improved efficiency stemming from selecting the right PLC system tailored to specific industrial needs.