In today's rapidly evolving industrial landscape, the need for efficiency, precision, and real-time monitoring is more crucial than ever. This is where DCS systems (Distributed Control Systems) play a vital role, serving as the backbone of modern industrial automation. By integrating various processes into a cohesive framework, DCS systems enable operators to manage complex manufacturing environments with ease and accuracy. The shift towards automation in industries such as oil and gas, chemical production, and power generation highlights the importance of these systems in enhancing operational efficiencies and ensuring safety compliance.

As industries face increasing demands for productivity and reliability, DCS systems provide a robust solution that facilitates better control over production processes. Through their ability to gather data from multiple sources and deliver insights in real-time, these systems empower organizations to make informed decisions that drive improvements. Furthermore, DCS systems enhance process consistency and optimize resource utilization, leading to significant cost reductions and minimized downtime. Ultimately, the relevance of DCS systems in modern industrial automation cannot be overstated, as they are essential for achieving operational excellence and maintaining a competitive edge in the market.

Distributed Control Systems (DCS) represent a critical backbone of modern industrial automation, enabling enhanced reliability, efficiency, and flexibility across various sectors. A DCS integrates complex processes, allowing for real-time data collection, monitoring, and control. According to a report from MarketsandMarkets, the global DCS market is projected to reach $22.76 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.7%. This growth underscores the essential role DCS systems play in improving operational efficiency and reducing downtime in industries such as oil and gas, chemicals, and pharmaceuticals.

Moreover, DCS systems facilitate centralized control by distributing control functions across various subsystems, which is crucial in managing large-scale operations. According to an industry analysis by ResearchAndMarkets, 60% of manufacturing facilities are adopting DCS to harness the advantages of increased process visibility and improved decision-making capabilities. This transition towards automation is not only attributed to the need for enhanced productivity but also driven by stringent regulatory compliance and the necessity for safer operational environments. By implementing DCS, companies are better positioned to respond to real-time demands and adapt to the rapid changes in industrial processes.

| Dimension | Description | Importance |

|---|---|---|

| Scalability | DCS systems can be expanded to accommodate new processes without major overhauls. | Allows for growth and adaptation to changing production demands. |

| Integration | Easily integrates with various systems and equipment in the production environment. | Enhances operational efficiency by enabling communication between devices. |

| Real-time Monitoring | Provides continuous data access and monitoring of industrial processes. | Facilitates informed decision-making and quick responses to issues. |

| Safety | Incorporates safety systems that monitor and control hazardous conditions. | Minimizes risks to personnel and equipment, ensuring a safer operational environment. |

| Cost Efficiency | Optimizes resource allocation and minimizes operating costs through better process control. | Improves overall profitability and competitiveness of production operations. |

Distributed Control Systems (DCS) play a pivotal role in modern industrial automation, supporting a range of applications from manufacturing to process control. A DCS architecture is comprised of several key components that enhance operational efficiency and reliability. At the core are the sensors and actuators, which gather real-time data from the field and execute control commands. According to a report by ARC Advisory Group, the market for DCS solutions is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2020 to 2025, underscoring the increasing reliance on advanced control systems in industries.

Another essential aspect of DCS is the centralized control room, where operators monitor system performance and make data-driven decisions. Human-Machine Interfaces (HMIs) facilitate this interaction, providing intuitive visualization of complex processes. Additionally, the integration of advanced data analytics tools within the DCS framework enables predictive maintenance and operational optimization. According to a 2021 study published by MarketsandMarkets, predictive maintenance technologies are projected to reach $12.3 billion by 2025, indicating a significant shift towards data-centric approaches in industrial environments. This synergy of key components, including HMIs, data analytics, and robust networking capabilities, solidifies the DCS as a critical element in enhancing productivity and safety in contemporary industrial settings.

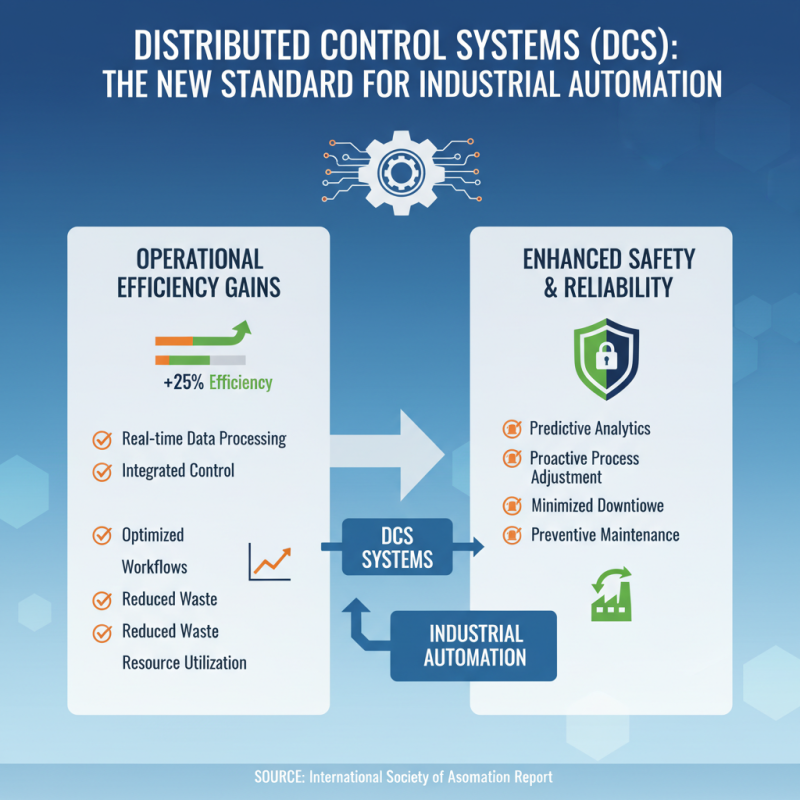

Distributed Control Systems (DCS) have become a cornerstone of modern industrial automation, particularly due to their significant contributions to operational efficiency and safety. According to a recent report by the International Society of Automation, DCS systems can enhance operational efficiency by up to 25% by providing real-time data processing and integrated control functionality. This allows organizations to optimize their workflows, reduce waste, and improve the overall utilization of resources. Furthermore, advanced algorithms in DCS systems enable predictive analytics, allowing operators to adjust processes proactively, minimizing downtime and preventing costly production interruptions.

Safety is another critical area where DCS systems demonstrate their value. The same report highlights that industries implementing DCS have seen a reduction in safety incidents by about 30%, owing to the system's ability to provide continuous monitoring and alarm functions. By integrating safety protocols directly into the control architecture, engineers can ensure that dangerous conditions are detected and mitigated swiftly. This level of monitoring is vital in sectors such as oil and gas, where the consequences of safety failures can be dire. Overall, as industries strive for higher efficiency and robust safety measures, the integration of DCS systems is proving to be not just beneficial, but essential in today’s complex industrial environments.

The integration of Distributed Control Systems (DCS) with modern technology and the Internet of Things (IoT) is transforming industrial automation. By enabling seamless communication between various devices, sensors, and control systems, DCS plays a crucial role in enhancing operational efficiency. IoT applications collect real-time data across the production line, which can be processed by DCS to optimize performance and predict maintenance needs. This synergy enables industries to transition from reactive to proactive maintenance strategies, ultimately reducing downtime and lowering operational costs.

Moreover, the convergence of DCS and IoT facilitates advanced analytics and machine learning applications. With the vast amounts of data generated by connected devices, organizations can leverage sophisticated algorithms to gain deeper insights into their processes. These insights not only help in identifying inefficiencies but also drive innovation in product development and manufacturing techniques. As industries continue to embrace smart technologies, the incorporation of DCS into IoT ecosystems will be pivotal in transforming traditional automated systems into intelligent, self-learning operations that adapt in real-time to changing conditions.

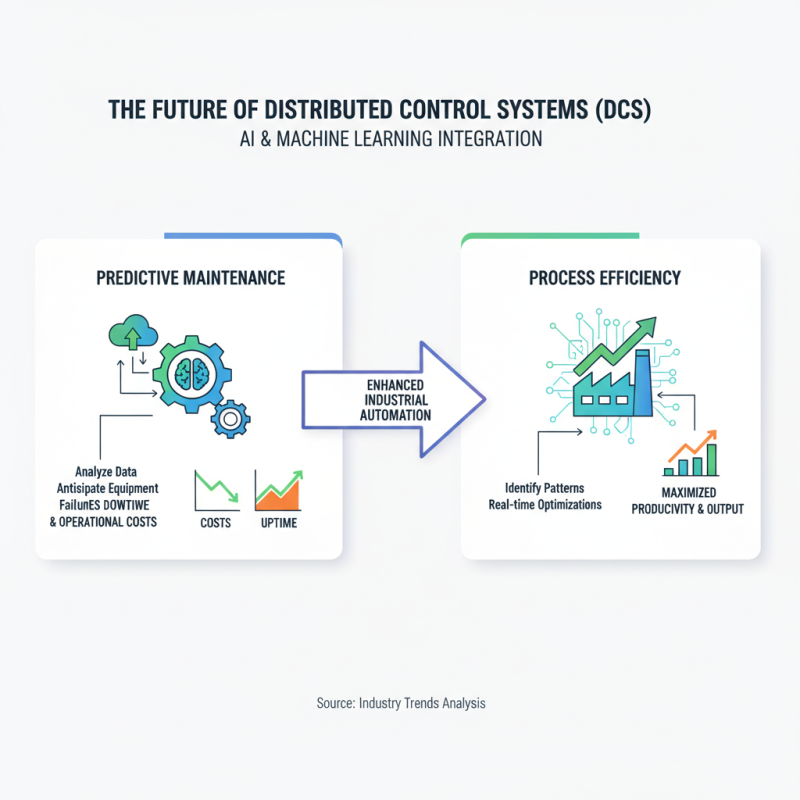

As industries continue to evolve, the future of Distributed Control Systems (DCS) is poised to significantly enhance industrial automation. One of the most notable trends is the integration of artificial intelligence and machine learning into DCS platforms. This advancement allows for predictive maintenance, where systems can analyze vast amounts of data to anticipate equipment failures before they happen, reducing downtime and minimizing operational costs. Additionally, AI-driven analytics can improve process efficiency by identifying patterns and suggesting real-time optimizations, thereby maximizing productivity.

Another emerging trend is the shift towards cloud-based DCS solutions. By leveraging cloud technologies, industries can benefit from greater scalability and flexibility. This enables organizations to access their DCS from anywhere, facilitating remote monitoring and control, which is increasingly important in today's globalized economy. Moreover, cloud integration allows for enhanced data integration across different systems and devices, paving the way for more cohesive automation strategies. These advancements not only streamline operations but also enhance collaboration between teams and improve response times to market changes. As these trends continue to develop, they will fundamentally reshape how industries approach automation, driving them towards more intelligent, connected, and efficient operations.