In the era of rapid technological advancements, businesses are increasingly turning to digital transformation strategies to enhance operational efficiency, particularly in Plc Automation. According to a report by Mckinsey, companies that adopt digital tools in their manufacturing processes can achieve up to a 30% boost in efficiency, underscoring the significance of integrating automation systems with digital technologies. A study by the International Society of Automation highlights that 70% of manufacturers consider automation a key factor in driving their digital transformation efforts. By leveraging Plc Automation alongside advanced data analytics and machine learning, organizations are not only optimizing their processes but also gaining valuable insights to improve decision-making and reduce downtime. As the industry moves towards smart manufacturing, understanding and implementing effective digital strategies in Plc Automation will be crucial for companies aiming to stay competitive and enhance productivity in this fast-evolving landscape.

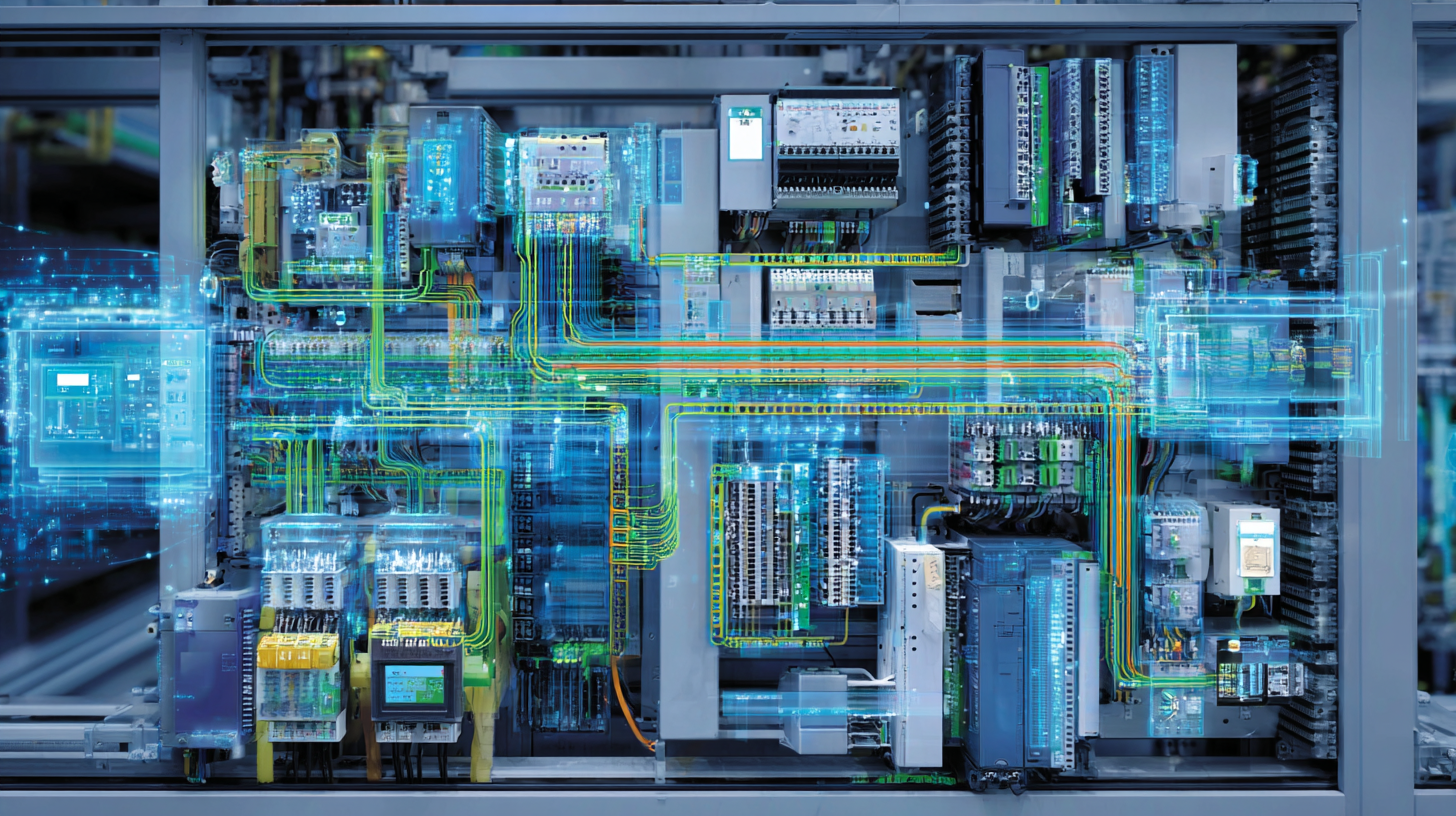

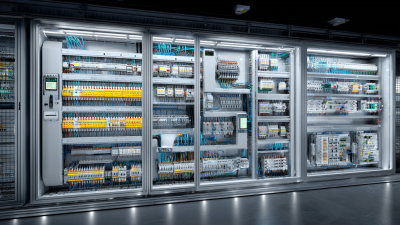

Digital transformation in PLC (Programmable Logic Controller) automation is revolutionizing the way industries operate. By integrating advanced technologies such as IoT, data analytics, and cloud computing, companies are able to enhance their operational efficiency significantly. This transformation not only streamlines processes but also enables real-time monitoring and predictive maintenance, reducing downtime and optimizing resource allocation.

To leverage digital transformation effectively, organizations should focus on a few key strategies. **Tip 1:** Begin with a clear assessment of existing systems and identify areas for improvement. It’s essential to understand the unique needs of your operations to implement the most effective solutions. **Tip 2:** Invest in training and education for your workforce. Ensuring that employees are well-versed in new technologies will maximize the benefits of automation and foster a culture of continuous improvement.

Another critical aspect of this transformation is data management. **Tip 3:** Utilize robust data analytics tools to gather insights from your automated processes. This data can inform decision-making, leading to more effective strategies and ultimately driving the desired efficiency boost. Embracing digital transformation in PLC automation not only improves productivity but also positions companies for long-term success in an increasingly competitive landscape.

The digital transformation in PLC (Programmable Logic Controller) automation plays a crucial role in enhancing operational efficiency. By integrating advanced technologies, industries can achieve up to a 30 percent boost in their overall performance. One of the key technologies driving this efficiency is the Internet of Things (IoT). IoT facilitates real-time data collection and analysis from connected devices, allowing for timely decision-making and predictive maintenance. This connectivity not only reduces downtime but also optimizes resource utilization, streamlining industrial processes significantly.

Another critical technology is cloud computing, which enables seamless data sharing and collaboration across various operational platforms. By harnessing the power of the cloud, companies can store vast amounts of data and access robust analytics tools that provide insights into system performance. This facilitates improved monitoring and control of PLC systems, leading to more agile responses to production demands. Moreover, the integration of artificial intelligence (AI) into PLC systems further enhances efficiency by enabling advanced algorithms to automate processes, detect anomalies, and predict equipment failures proactively, ensuring smooth and uninterrupted operations.

The integration of data analytics in Programmable Logic Controller (PLC) systems is pivotal for industries aiming to enhance their operational efficiency. Recent studies reveal that incorporating analytics can lead to up to a 30% increase in system efficiency. By analyzing real-time production data, companies can uncover insights that optimize processes and minimize downtime. According to a report from Allied Market Research, the industrial automation sector is expected to grow significantly, driven by the adoption of data-driven solutions. This shift not only improves PLC performance but also fosters a more proactive maintenance culture.

**Tip:** To maximize the benefits of data analytics in PLC automation, invest in training your workforce. Employees equipped with data interpretation skills can identify issues efficiently and implement corrective measures quickly.

Moreover, leveraging predictive analytics helps in foreseeing potential failures before they occur. By employing advanced machine learning algorithms, industries can analyze historical data and predict equipment degradation, thereby scheduling maintenance proactively. This approach not only reduces unexpected breakdowns but also extends the lifespan of machinery, further solidifying the case for digital transformation.

**Tip:** Consider using cloud-based analytics platforms to store and process your operational data. This centralized access allows for comprehensive analysis and enhances collaboration across teams.

This chart illustrates the impact of data analytics on PLC performance improvement. As shown, the efficiency increased from 70% before the implementation of data analytics to 90% afterward, reflecting a significant boost in operational performance.

Digital transformation is becoming increasingly critical in PLC automation, with companies aiming for significant efficiency boosts—up to 30 percent. Implementing this transformation requires strategic planning and a clear understanding of automation technologies. One effective approach is to leverage Robotic Process Automation (RPA) to streamline operations. By focusing on rule-based automation, businesses can enhance productivity and reduce human error, leading to smoother workflows and better resource allocation.

**Tips:** When considering RPA, start by identifying repetitive tasks that consume valuable time. Automating these processes can yield immediate benefits in efficiency. Additionally, ensure that your team is on board with the changes; proper training and communication are key to a successful transition to a more automated environment.

Understanding the industrial software market's growth, projected to reach $7406 million by 2034, also highlights the importance of digital tools in automation. Investing in the right software solutions can provide the necessary infrastructure for digital transformation. Be sure to conduct thorough market research to select solutions that align with your specific operational goals and support integration with existing systems.

**Tips:** Evaluate various industry players and their offerings to find software that not only meets your current needs but can also scale as your organization evolves. Regularly revisiting and adjusting your strategies will ensure continued alignment with technological advancements.

| Strategy | Description | Expected Efficiency Boost (%) | Implementation Timeline |

|---|---|---|---|

| Cloud Integration | Integrating cloud-based solutions for real-time data analysis. | 10 | 3 Months |

| Data Analytics | Leveraging data insights to streamline production processes. | 15 | 6 Months |

| IoT Implementation | Utilizing IoT devices for monitoring and controlling equipment. | 20 | 9 Months |

| Automation of Manual Processes | Automating repetitive tasks to reduce human error. | 25 | 1 Year |

| Predictive Maintenance | Using predictive analytics to anticipate equipment failures. | 30 | 18 Months |

In the realm of PLC (Programmable Logic Controller) automation, digital transformation strategies have proven to be instrumental in achieving significant efficiency boosts. Several case studies illustrate how organizations have harnessed advanced technologies, such as IoT and AI, to streamline operations and reduce downtime. For instance, a leading manufacturing firm integrated predictive maintenance tools within its PLC framework, facilitating real-time monitoring and analytics. This proactive approach resulted in a remarkable 30% increase in overall equipment efficiency, drastically cutting costs and enhancing production capabilities.

Moreover, another case study highlights a food processing company that revamped its PLC automation system by incorporating cloud-based solutions. By enabling remote access and data-driven decision-making, the company not only improved operational agility but also enhanced its response time to market demands. As a result, the organization achieved a 30% boost in production efficiency, illustrating the transformative power of digital initiatives in traditional manufacturing environments. These examples underscore the pivotal role that PLC automation plays in driving efficiency and competitiveness in an increasingly digital landscape.