In the rapidly evolving landscape of technology, the realm of World Industrial Automation stands at the forefront of innovation. As we delve into 2023, it becomes increasingly evident that a myriad of digital trends are reshaping this sector, paving the way for unprecedented efficiencies and advancements. This year marks a pivotal moment where traditional manufacturing paradigms are being disrupted by cutting-edge technologies, driving industries to adapt and evolve in ways previously thought unimaginable.

From the integration of artificial intelligence and machine learning to the rise of Internet of Things (IoT) devices, these digital trends are not only enhancing operational capabilities but also revolutionizing the way businesses approach automation. The convergence of these technologies is facilitating smarter decision-making processes, optimizing resource management, and improving overall productivity across diverse industrial applications. As organizations strive to remain competitive in an increasingly digital world, recognizing and harnessing these trends is essential for sustaining growth and innovation.

In this exploration of the top 10 digital trends shaping the future of World Industrial Automation, we aim to illuminate the transformative potential that these advancements hold. By understanding the nuances of these trends, industry leaders can strategically navigate the challenges and opportunities that lie ahead, ensuring that their operations are not just current but also future-ready in an age defined by rapid technological change.

In 2023, the landscape of industrial automation is significantly shaped by a series of digital trends, reflecting a broader movement towards

integration and intelligence in manufacturing processes. The global market for

artificial intelligence is projected to surge from $35.65 billion in 2023 to

$253.86 billion by 2030, boasting a compound annual growth rate (CAGR) of 32.4%. This immense growth signals

the increasing reliance on smart technologies across various sectors, particularly in process industries where automation plays

a critical role in enhancing efficiency and product quality.

As we look towards 2030, China's smart manufacturing sector is set for exponential growth, driven by three key technological trends:

platformization, agility, and the continued rise of Industry 4.0. The

global digital transformation market, currently valued at

$1.96 trillion, anticipates an extraordinary growth trajectory to reach $10.94 trillion by 2032, with

a CAGR of 22%. Such rapid advancements in digital capabilities indicate not only a shift in operational approaches but also

a redefinition of competitive landscapes, where adaptability and data-driven

decision-making will be paramount for success in the industrial sector.

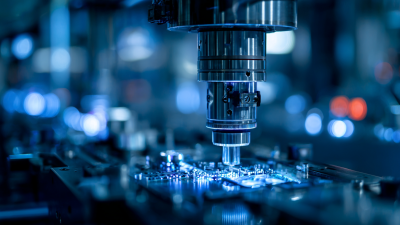

The integration of AI and machine learning into industrial automation is revolutionizing predictive maintenance and process optimization, marking a significant shift in operational efficiency. Predictive maintenance utilizes sophisticated algorithms that analyze vast amounts of data collected from machinery and equipment. By identifying patterns and anomalies, these AI systems can accurately predict when a machine is likely to fail, allowing companies to perform maintenance just in time. This proactive approach not only reduces downtime but also minimizes unexpected repair costs, leading to significant savings and enhanced productivity.

Moreover, machine learning enhances process optimization by continuously learning from operational data and improving workflows over time. With the ability to analyze the performance of processes in real time, AI can suggest adjustments to maximize efficiency, reduce waste, and improve product quality. By implementing these advanced technologies, industries can harness data-driven insights to refine their operations, accelerate decision-making, and ultimately gain a competitive edge in an increasingly digital landscape. As we move through 2023, the impact of AI in industrial settings continues to grow, driving a transformation that is both innovative and essential for future success.

| Trend | Description | Benefits | Implementation Challenges |

|---|---|---|---|

| AI and Machine Learning | Utilizing algorithms to analyze data and forecast maintenance needs. | Improved efficiency and reduced downtime in maintenance. | Data privacy concerns and integration with existing systems. |

| IoT Integration | Connecting devices to collect and exchange data in real-time. | Enhanced monitoring and control of industrial processes. | Interoperability between devices and security issues. |

| Cloud Computing | Storing and analyzing industrial data in the cloud. | Scalability and reduced IT overhead. | Latency and dependence on internet connectivity. |

| Edge Computing | Processing data closer to the source to minimize latency. | Quicker data processing and response times. | Complex architecture and management of distributed resources. |

| Digital Twin Technology | Creating virtual replicas of physical systems for analysis. | Improved design, prediction, and optimization of systems. | High initial setup costs and data synchronization issues. |

| Cybersecurity Enhancements | Implementing strong security measures to protect industrial systems. | Increased protection of sensitive data and systems. | Ongoing investment and continuous updates required. |

| Robotic Process Automation (RPA) | Automating routine tasks through software robots. | Increased productivity and reduced human error. | Change management and employee resistance to automation. |

| 5G Connectivity | Implementing high-speed wireless networks for reliable connectivity. | Support for IoT devices and real-time data transmission. | Infrastructure upgrades and regulatory hurdles. |

| Augmented Reality (AR) | Using AR to facilitate training and maintenance processes. | Enhanced learning experiences and reduced training time. | Navigating technology adoption and content creation. |

| Sustainability Solutions | Implementing eco-friendly practices and technologies. | Long-term cost savings and improved brand image. | Initial investment and changing industry standards. |

The Industrial Internet of Things (IIoT) is revolutionizing the landscape of industrial automation in 2023, enabling organizations to connect systems and enhance data visibility and control. According to a report by McKinsey, the potential economic impact of IIoT could range between $3.9 trillion to $11.1 trillion by 2025. This substantial growth underscores the importance of integrating smart devices across the manufacturing sector, where real-time monitoring and data analytics can lead to optimized operational efficiency.

With IIoT, companies can harness the power of connected devices to facilitate better decision-making and predictive maintenance. A study by IDC indicates that 70% of manufacturers are investing in IIoT technologies to improve productivity and reduce downtime. By utilizing advanced sensors and data analytics, businesses can gain insights into machine performance, predict failures, and streamline maintenance schedules, resulting in significant cost savings and enhanced productivity. This level of connectivity not only fosters a more responsive manufacturing environment but also sets the stage for innovation in product development and supply chain management.

The integration of 5G technology is revolutionizing the landscape of industrial automation in 2023, particularly through its impact on real-time data transmission. According to a report by the International Data Corporation (IDC), the adoption of 5G in industrial settings is projected to enhance data transmission speeds by up to 100 times compared to 4G. This leap facilitates the instant transfer of large volumes of data from IoT devices and machinery, making it crucial for real-time decision-making and process optimization in manufacturing environments.

With 5G’s ultra-reliable low latency communication (URLLC), industries can expect a significant boost in automation efficiency. A study from McKinsey suggests that factories leveraging 5G can achieve operational improvements of up to 30%, driven by enhanced monitoring and predictive maintenance capabilities. This not only minimizes downtime but also maximizes productivity. The connected devices can seamlessly interact with each other, enabling a level of automation that was previously unattainable.

Tips:

To fully leverage the benefits of 5G in industrial automation, companies should invest in upgrading their network infrastructure and training their workforce on emerging technologies. Additionally, implementing a phased approach to 5G deployment can help manage costs while maximizing returns. Keeping abreast of industry best practices will ensure organizations stay ahead in the fast-evolving digital landscape.

In 2023, sustainability has emerged as a pivotal factor in redefining automation standards within the industrial sector. A report from McKinsey indicates that companies focused on sustainability are not only contributing to environmental preservation but are also achieving a competitive advantage. For instance, firms that prioritize eco-friendly innovations have reported up to 15% higher efficiency in operational processes, showcasing that reducing waste and optimizing energy use can lead to significant cost savings.

Furthermore, the adoption of green technologies is rapidly increasing, with a forecasted market growth of sustainable automation technologies projected to reach $300 billion by 2025, according to a recent analysis by MarketsandMarkets. This burgeoning industry is characterized by the integration of smart sensors and AI-driven analytics that enhance resource utilization while reducing carbon footprints. As industries pivot towards renewable energy and circular economy principles, automation will play a crucial role in achieving sustainability goals, thereby transforming operational frameworks and setting new benchmarks for eco-friendly practices in the manufacturing landscape.