As the 138th Canton Fair approaches in 2025, the spotlight on Automation Systems is set to illuminate the future of manufacturing and trade in China. According to recent industry reports, the global automation market is expected to reach approximately $387 billion by 2026, with a compound annual growth rate (CAGR) of 9.23%. This growth underscores the critical role that Automation Systems play in enhancing operational efficiency, reducing costs, and improving product quality.

The fair will serve as a pivotal platform for industry leaders to showcase revolutionary automation technologies that drive productivity and innovation. As China continues to ramp up its technological capabilities, the integration of advanced automation solutions is anticipated to not only transform traditional manufacturing processes but also elevate the competitiveness of Chinese exports in the international market. With the advent of Industry 4.0, the 138th Canton Fair presents a unique opportunity for stakeholders to engage in meaningful discussions and partnerships focused on leveraging automation for sustainable growth.

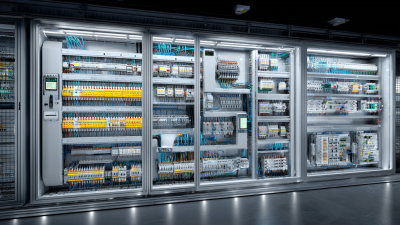

At the 138th Canton Fair, innovation in automation technologies was at the forefront, showcasing the latest advancements that are reshaping the landscape of industry and manufacturing. Exhibitors presented cutting-edge automation solutions that enhance productivity, streamline operations, and reduce costs. From robotic process automation to sophisticated AI-driven systems, the fair highlighted technologies designed to meet the rapidly evolving demands of the market.

One notable trend was the integration of Internet of Things (IoT) capabilities in automation systems, enabling real-time monitoring and data collection to optimize performance. Attendees were particularly impressed by smart manufacturing equipment that can adapt to various production requirements with minimal human intervention. This focus on efficiency not only promises to revolutionize production lines but also emphasizes the importance of sustainability, as manufacturers are increasingly looking for ways to minimize waste and energy consumption in their operations.

The automation industry in China is undergoing a transformative shift, driven by simplified AI application development methods that enhance internal telecommunications growth. According to McKinsey's 2030 outlook, the integration of AI technologies in telecom operations is vital for improving efficiency and service delivery.

This trend is underscored by a significant increase in spending on industrial automation products across various sectors, particularly process industries that rely heavily on intricate mixing techniques. These industries are increasingly adopting AI-driven solutions to streamline their production processes, ensuring greater operational effectiveness.

The automation industry in China is undergoing a transformative shift, driven by simplified AI application development methods that enhance internal telecommunications growth. According to McKinsey's 2030 outlook, the integration of AI technologies in telecom operations is vital for improving efficiency and service delivery.

This trend is underscored by a significant increase in spending on industrial automation products across various sectors, particularly process industries that rely heavily on intricate mixing techniques. These industries are increasingly adopting AI-driven solutions to streamline their production processes, ensuring greater operational effectiveness.

Furthermore, the global market for automation solutions is projected to expand significantly, with a focus on intelligent manufacturing facilities employing advanced technologies such as robotics and data analytics. The intelligent factory market is expected to see substantial growth by 2031, leveraging the benefits of IoT connectivity and smart processes. As businesses across sectors embrace digital transformation, the move toward operational efficiency and sustainability remains a paramount goal, highlighting the essential role of automation in the future of manufacturing in China.

At the 138th Canton Fair in 2025, automation systems will take center stage, showcasing remarkable case studies of successful implementations that underscore the growing trend of digital transformation in the manufacturing sector. According to a recent report from the International Federation of Robotics, the global market for industrial robots is projected to reach $70 billion by 2028, reflecting a compound annual growth rate (CAGR) of 15%. This surge highlights the critical role that automation is playing in enhancing efficiency and productivity across various industries, a fact that will be vividly illustrated through real-world examples at the fair.

One notable case study involves a leading electronics manufacturer that integrated advanced automated assembly lines, resulting in a 30% increase in production speed and a 25% reduction in labor costs. Such implementations not only streamline operations but also significantly minimize human error, creating a more reliable manufacturing process. Additionally, with insights drawn from a McKinsey report, automation could potentially boost productivity by up to 40% in sectors like logistics and warehousing. The case studies presented at the fair will provide a comprehensive view of how these technologies can be effectively harnessed to drive efficiency, making it a pivotal event for industry professionals seeking to remain competitive in an increasingly automated world.

The 138th Canton Fair in 2025 promises to be a pivotal event for automation professionals, presenting unparalleled networking opportunities. Attendees from across the globe will gather to exchange insights on the latest trends and innovations in automation technology. Whether individuals are seeking to forge new partnerships or expand their knowledge base, the fair serves as a platform where industry leaders and newcomers alike can connect. Participation in workshops and panel discussions will further enhance collaboration, fostering an environment ripe for idea exchange.

Moreover, the unique format of the Canton Fair encourages networking beyond conventional limits. With a diverse range of exhibitors showcasing their advancements, professionals can engage in meaningful conversations with vendors, suppliers, and potential collaborators. This setting not only facilitates business relationships but also stimulates discussions about best practices and emerging technologies in automation.

The connections made here could lead to future projects, strategic alliances, and even career advancements, making it an unmissable event for anyone in the automation sector.

At the 138th Canton Fair in 2025, the impact of automation on China's manufacturing landscape will be a pivotal theme, reflecting the industry’s ongoing transformation. According to a report by McKinsey, automation could increase China’s labor productivity by up to 30% by 2030. This shift not only enhances operational efficiency but also reshapes workforce dynamics, as manufacturers integrate advanced technologies like robotics and AI. The result is a more streamlined production process that allows businesses to respond quickly to market demands.

Further data from a study by Boston Consulting Group suggests that by 2025, about 25% of manufacturing jobs in China could be replaced by automation technologies. However, this transition is not solely about job displacement; it opens avenues for highly skilled positions in tech and machine maintenance. As the government prioritizes innovation and automation within its "Made in China 2025" strategy, the future of manufacturing is set to be characterized by smart factories where IoT and data analytics play crucial roles in maximizing productivity and minimizing waste. Such advancements promise to position China at the forefront of global manufacturing excellence.

| Automation Technology | Adoption Rate (%) | Impact on Productivity (%) | Cost Reduction (%) | Future Growth Potential (%) |

|---|---|---|---|---|

| Industrial Robotics | 65 | 30 | 20 | 40 |

| Process Automation | 58 | 25 | 15 | 35 |

| AI & Machine Learning | 72 | 40 | 25 | 50 |

| IoT Integration | 55 | 20 | 10 | 45 |

| Cloud Computing | 50 | 22 | 12 | 38 |