In today's rapidly evolving industrial landscape, the integration of Low Cost PLCs with HMI is emerging as a pivotal strategy for enhancing operational efficiency. According to a report by MarketsandMarkets, the global industrial automation market is projected to reach USD 295.2 billion by 2023, driven in part by the increasing adoption of cost-effective automation solutions. These affordable programmable logic controllers (PLCs) equipped with Human Machine Interfaces (HMIs) not only promise reduced capital expenditure but also facilitate improved monitoring and control processes, leading to significant productivity gains.

As industries strive to optimize their operations amidst growing competitive pressures, Low Cost PLCs with HMI stand out as essential tools that empower manufacturers to streamline workflows, enhance data visibility, and ultimately achieve their efficiency goals.

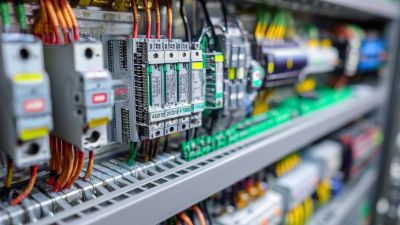

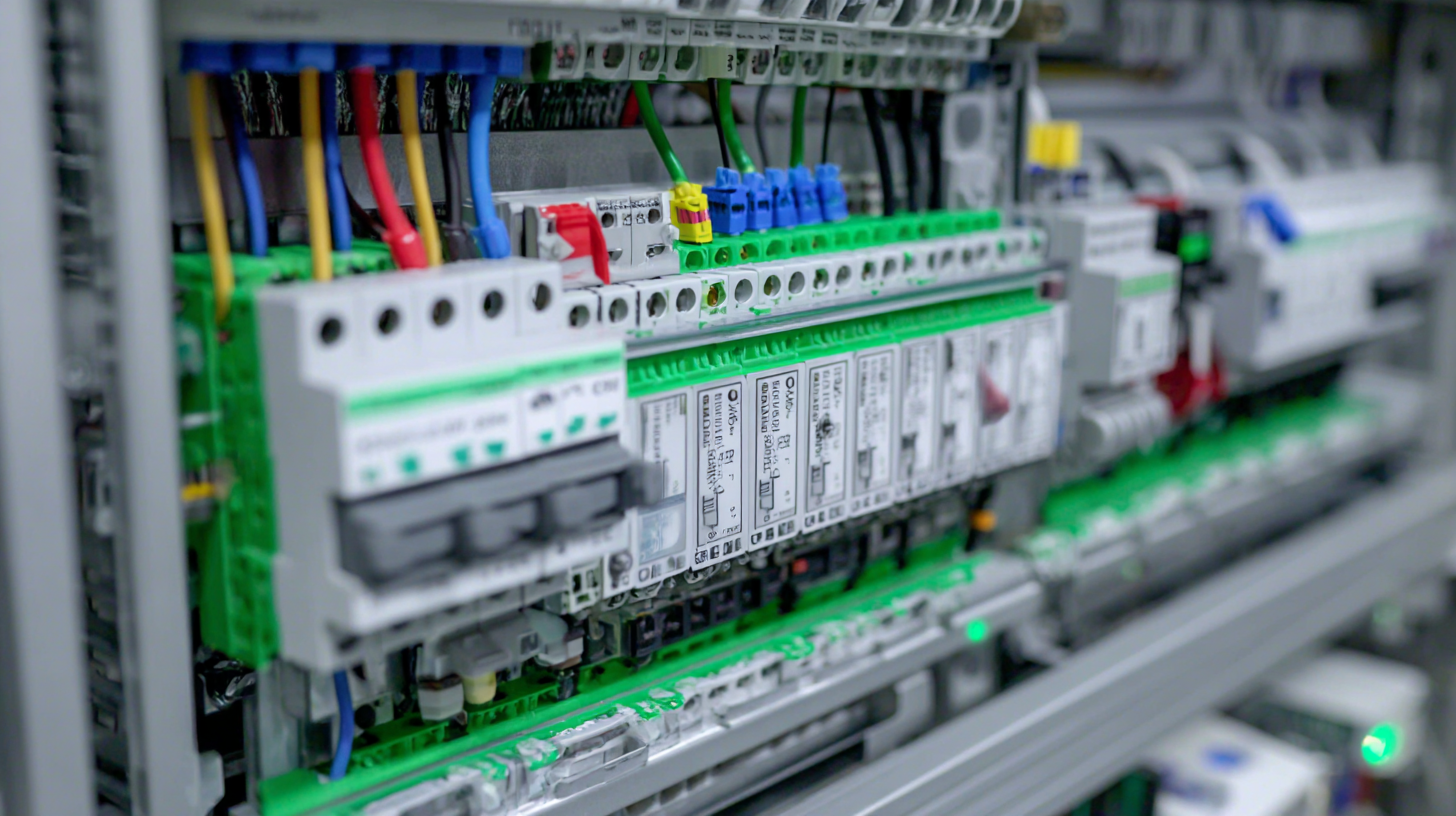

In modern automation systems, low-cost Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) have emerged as pivotal components that enhance operational efficiency. Low-cost PLCs are compact devices that manage and control various industrial automation systems, enabling them to perform tasks with minimal complexity and expense. Their affordability allows businesses, especially small and medium enterprises, to adopt advanced automation technologies without significant financial strain, thereby streamlining their processes and improving productivity.

Similarly, HMIs play a fundamental role in the interaction between operators and machines. These user-friendly interfaces provide operators with real-time data visualization and control capabilities, simplifying the monitoring and adjustment of automated processes. With the integration of low-cost PLCs and HMIs, companies can achieve effective communication between their machinery and workforce, reducing downtime and increasing the overall reliability of their operations. The combination of these technologies not only makes automation more accessible but also empowers businesses to innovate and remain competitive in an ever-evolving market.

The integration of low-cost Programmable Logic Controllers (PLCs) equipped with Human-Machine Interfaces (HMIs) is transforming industrial automation by enhancing efficiency and reducing operational costs. According to a report by MarketsandMarkets, the global PLC market is projected to reach $11.8 billion by 2025, driven largely by advancements in low-cost automation solutions. These affordable PLCs offer manufacturers an opportunity to streamline processes without a hefty investment, enabling quicker adaptation to market changes.

One of the key benefits of implementing low-cost PLCs is their ability to facilitate real-time data monitoring and control. A study by Research and Markets indicates that the demand for real-time data analytics in manufacturing has surged, as organizations strive to improve productivity by up to 20%. By integrating low-cost PLCs with intuitive HMIs, operators can easily access critical data and make informed decisions swiftly, significantly enhancing the overall operational efficiency. Furthermore, these systems often come with user-friendly interfaces that reduce the training time needed for staff, resulting in a smoother transition and quicker returns on investment.

| Feature | Low-Cost PLC | Traditional PLC |

|---|---|---|

| Initial Investment Cost | Low | High |

| Programming Complexity | User-friendly | Moderate to High |

| Integration with HMI | Seamless | Often Complex |

| Scalability | High | Limited |

| Support and Community | Growing | Established |

| Maintenance Costs | Low | Moderate to High |

The integration of Human Machine Interfaces (HMIs) with low-cost Programmable Logic Controllers (PLCs) is revolutionizing the automation landscape. According to a recent report from MarketsandMarkets, the global HMI market is expected to grow from $5.7 billion in 2021 to $9.4 billion by 2026, highlighting the increasing demand for user-friendly interfaces in industrial applications. By combining HMIs with low-cost PLCs, manufacturers can significantly enhance user experience, allowing operators to easily monitor and control complex processes without extensive training.

Furthermore, the adoption of low-cost PLCs equipped with robust HMIs can lead to substantial reductions in operational costs. A study by Research and Markets indicates that companies using these integrated systems can achieve efficiency gains of up to 30%, thanks to improved data visualization and streamlined operations. This not only accelerates decision-making but also minimizes downtime, ultimately driving productivity. As automation continues to evolve, the seamless interplay between HMIs and low-cost PLCs is poised to set new standards for user engagement and operational excellence.

The comparative analysis of low-cost PLCs (Programmable Logic Controllers) and traditional automation solutions reveals significant advantages in modern automation environments. Recent market studies indicate that the global low-cost PLC market is experiencing notable growth, expected to reach $3.7 billion by 2035 with a CAGR of approximately 13%. This rapid expansion highlights the increasing reliance on these affordable automation solutions, particularly as manufacturers strive to optimize production efficiency while managing costs.

Furthermore, the integration of AI technologies in low-cost PLC systems is driving innovation across the industry. With over 66% of CEOs recognizing the transformative impact of AI, the enhancement of fault detection techniques in automated manufacturing systems is particularly noteworthy. These advancements enable companies to implement proactive measures, reducing downtime and improving overall system reliability. As industries transition towards Industry 4.0, the shift toward virtual PLCs demonstrates the industry's commitment to leveraging cutting-edge information technologies that enhance both scalability and flexibility in automation architectures.

This chart compares the efficiency, cost, and implementation time for Low-Cost PLCs with HMI and Traditional Automation Solutions. The data illustrates how low-cost PLCs can provide significant advantages in modern automation settings.

The adoption of low-cost PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces) has proven to be a game-changer in modern automation. Real-world case studies have demonstrated how these affordable technologies can significantly enhance operational efficiency in various industries. For instance, a water treatment facility implemented low-cost PLCs and HMIs to streamline their monitoring and control processes, resulting in reduced downtime and improved resource management. The case study highlights how small to medium enterprises can leverage these technologies to compete with larger corporations by optimizing their operations without enormous capital expenditure.

Tips for successful implementation include starting with a clear understanding of your automation needs and selecting PLCs and HMIs that offer scalability and compatibility with existing systems. Additionally, engaging employees in the training process can foster a more smooth transition and bolster user adoption. Encouraging collaboration, as seen in recent initiatives focusing on smart water solutions, can also drive innovation and enhance project outcomes. By looking at these success stories, businesses can glean valuable insights into effective strategies for harnessing low-cost automation technologies to achieve remarkable efficiency gains.