In today's rapidly evolving industrial landscape, businesses are increasingly recognizing the necessity of adopting innovative solutions to stay competitive. One pivotal area that has emerged is **Manufacturing Automation**, which serves as a catalyst for enhancing operational efficiency and productivity. By integrating advanced technologies and smart systems into manufacturing processes, companies can streamline operations, reduce human error, and significantly lower production costs.

The significance of effectively harnessing Manufacturing Automation cannot be overstated, as it facilitates a more agile response to market demands and helps in optimizing resource utilization. This introduction of automation not only accelerates production timelines but also allows for greater flexibility, enabling manufacturers to pivot in response to new challenges and opportunities. As industries aim for higher operational benchmarks, it becomes essential to explore strategies that leverage automation technologies effectively.

Ultimately, enhancing Manufacturing Automation is not merely an option; it is a necessity for organizations aiming to thrive in a highly competitive environment. This article will delve into practical approaches and best practices for implementing automation solutions that foster sustainable growth and elevate performance metrics within the manufacturing sector.

The current landscape of manufacturing automation is rapidly evolving, driven by advancements in technology and a pressing need for efficiency and productivity. According to a report by the International Federation of Robotics, the global robot density in manufacturing has reached an average of 113 robots per 10,000 employees, signifying a strong trend towards increased automation in factories. This shift enables manufacturers to deliver higher quality products at a faster pace while optimizing labor costs.

In addition, a study published by McKinsey & Company highlights that up to 45% of tasks in the manufacturing sector can be automated using existing technologies. This potential presents a unique opportunity for organizations to rethink their workflows and integrate smart automation solutions that not only increase output but also enhance workplace safety. The integration of IoT (Internet of Things) devices is also playing a pivotal role, as they allow for real-time monitoring and predictive maintenance, further streamlining operations. As these technologies continue to mature, manufacturers must remain agile and ready to adopt innovative methods that will sustain their competitive advantage in an increasingly automated economy.

Enhancing manufacturing automation is crucial for driving efficiency and productivity in today's competitive landscape. One key area for improvement is the integration of data analytics into manufacturing processes. According to a report by McKinsey, companies that leverage advanced analytics can improve their productivity by up to 20%. By collecting and analyzing operational data in real-time, manufacturers can identify bottlenecks, monitor equipment performance, and optimize production schedules, leading to significant time and cost savings.

Another vital aspect is the adoption of robotics and artificial intelligence (AI). The International Federation of Robotics reported that the global robot density in manufacturing has increased by 20% from 2018 to 2021, suggesting a growing reliance on automation for tasks ranging from assembly to quality control. Implementing AI algorithms can further enhance these robotic systems, enabling them to learn from their environment and adapt their actions accordingly. This results in reduced downtime and improved output quality, which are essential for maintaining competitiveness in a rapidly changing market.

Lastly, investing in workforce training is crucial for maximizing the benefits of automation. A survey by PwC found that 74% of workers are willing to upskill in response to increased automation in their workplace. By equipping employees with the necessary skills to work alongside automated systems, manufacturers can foster a culture of innovation and continuous improvement, ensuring that both technology and workforce contribute to enhanced efficiency and productivity.

The manufacturing landscape is rapidly evolving, driven by technological innovations that significantly enhance productivity and efficiency. According to a report from McKinsey, advanced manufacturing technologies can boost productivity by up to 30% in certain sectors. Automation tools, including robotics and artificial intelligence, are at the forefront of this transformation, enabling manufacturers to optimize their operations and reduce downtime. For instance, the deployment of collaborative robots (cobots) has increased labor efficiency, allowing human workers to focus on complex tasks while robots handle repetitive operations.

Moreover, the integration of Internet of Things (IoT) devices into manufacturing processes has resulted in real-time data collection and analysis, facilitating smarter decision-making. Research conducted by PwC indicates that companies utilizing IoT can achieve a productivity increase of approximately 20%. By harnessing predictive analytics, manufacturers can foresee maintenance issues before they occur, minimizing disruptions and increasing overall efficiency. As these technological advancements continue to permeate the industry, they are not only enhancing productivity but also creating a more agile manufacturing environment that can respond swiftly to changing market demands.

This chart represents the impact of various technological innovations on manufacturing productivity over the past five years.

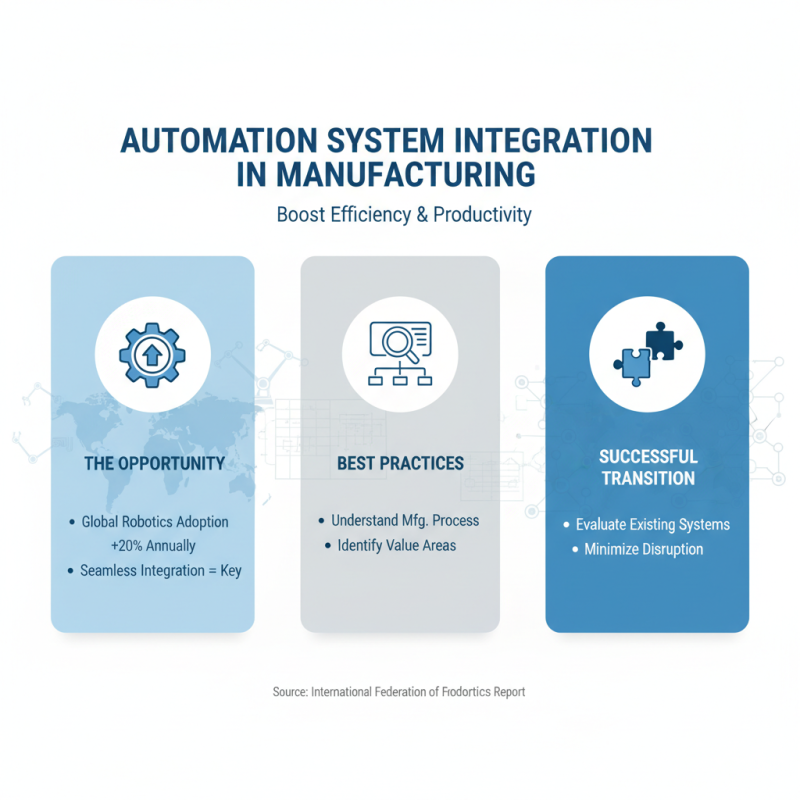

Implementing automation system integration in manufacturing is crucial for enhancing efficiency and productivity. According to a report by the International Federation of Robotics, global robotics adoption in manufacturing has increased by 20% annually, with businesses recognizing the need for seamless integration of automation technologies. Best practices for successful system integration begin with a clear understanding of the manufacturing process and identifying key areas where automation can add value. Manufacturers should evaluate existing systems and workflows to determine the best points of integration, facilitating a smoother transition and minimizing disruption.

Moreover, the integration of advanced analytics and Internet of Things (IoT) capabilities can further bolster automation efforts. A study from McKinsey & Company indicates that manufacturers that fully leverage IoT technologies can achieve productivity improvements of up to 30%. By connecting machinery and software systems, manufacturers can gain real-time insights into operational performance, allowing for data-driven decision-making that enhances productivity. Regular training and communication among teams are also vital, ensuring that employees understand the integrated systems and can effectively utilize them to drive efficiency. Prioritizing these best practices not only streamlines operations but also positions manufacturers to adapt to future technological advancements.

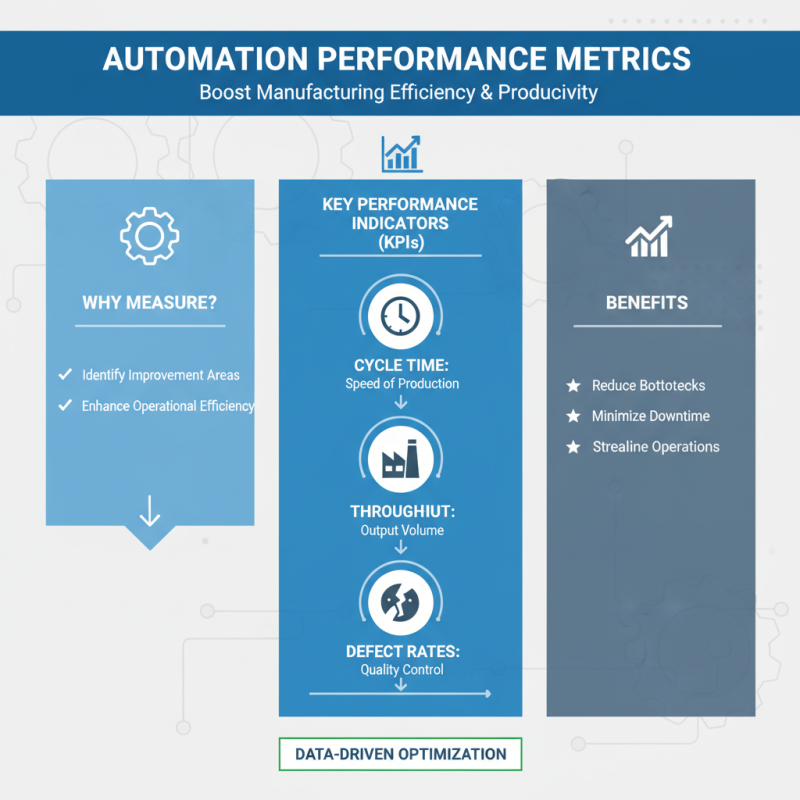

Measuring and analyzing performance outcomes in automation efforts is crucial for organizations looking to enhance manufacturing efficiency and productivity. By establishing clear performance metrics, businesses can pinpoint areas of improvement within their automated processes. Key performance indicators may include cycle time, throughput, and defect rates, which provide insight into how effectively machinery and systems are operating. Regularly assessing these metrics allows companies to identify bottlenecks, reduce downtime, and streamline operations, ultimately leading to a more efficient manufacturing environment.

Additionally, leveraging data analytics tools can significantly augment the analysis of performance outcomes. By collecting real-time data from automated systems, organizations can conduct in-depth trend analysis and predictive modeling. This enables them to foresee potential issues before they arise, allowing for proactive adjustments that enhance overall performance. Implementing ongoing training for staff to interpret and act on these insights ensures that automation efforts are continually optimized, fostering a culture of continuous improvement that drives productivity to new heights.