In an era where industrial operations are increasingly reliant on technology, the significance of robust Industrial Control Systems (ICS) cannot be overstated. As stated by Dr. Emily Rodriguez, a leading expert in industrial automation, "The effectiveness of any modern industrial operation hinges on the reliability and security of its control systems." With rising concerns over cybersecurity threats and the growing need for efficiency, organizations must prioritize the enhancement of their ICS to safeguard their infrastructure and optimize performance.

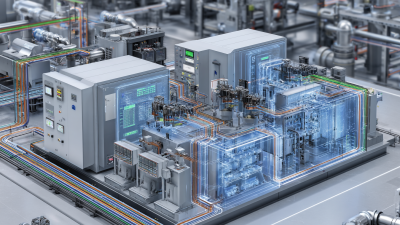

The advent of advanced technologies such as the Internet of Things (IoT) and artificial intelligence is transforming the ICS landscape, offering unprecedented opportunities for improved operational efficiency and security. However, this technological evolution also necessitates a comprehensive understanding of the essential systems that can bolster resilience against potential vulnerabilities. The top 10 essential ICS will not only streamline processes but also fortify defenses against unauthorized access and cyber threats, ensuring a safer and more productive industrial environment.

As industries face the dual challenges of advancing technology and escalating cyber threats, it is crucial to stay informed about the latest developments in Industrial Control Systems. By leveraging the right tools and strategies, organizations can enhance their security posture while achieving optimal operational efficiency, paving the way for a more secure and prosperous industrial future.

Industrial control systems (ICS) are crucial for the operations of various industries, ensuring smooth workflow and enhancing security protocols. Key characteristics of these essential systems include real-time monitoring capabilities, which enable operators to oversee processes and respond to issues promptly. The integration of advanced sensors and data analytics allows for continuous surveillance of machinery and environmental conditions, thereby minimizing downtime and improving overall efficiency. Implementing automated alerts can significantly enhance operational responsiveness, providing critical information to workers during emergencies.

Another defining characteristic of optimal industrial control systems is their scalability and flexibility. As industries expand and evolve, these systems should be capable of adapting to new technologies and processes without significant overhauls. This adaptability enables organizations to incorporate modern solutions such as IoT devices and AI-driven software, enhancing decision-making processes. Furthermore, robust cybersecurity measures are essential for protecting sensitive data and maintaining operational integrity. Secure communication protocols and access controls mitigate vulnerabilities, ensuring that industrial operations can withstand external threats while maintaining high levels of efficiency.

In today's industrial landscape, the intersection of security and operational efficiency is more critical than ever. Enhanced security measures within industrial control systems (ICS) significantly impact operational resilience and productivity. According to a report by the International Society of Automation, over 50% of organizations have reported increased operational downtime due to cyber incidents, averaging losses of approximately $1.1 million per incident. This digital vulnerability highlights the importance of robust security measures that not only protect against threats but also ensure uninterrupted operations.

The implementation of advanced security protocols leads to streamlined processes and a more agile response to potential threats. A study by Frost & Sullivan indicates that businesses that invest in enhanced security measures within their ICS can experience up to a 30% increase in overall operational efficiency. This improvement is largely attributed to the reduction of unauthorized access and the resulting minimization of system interruptions. Furthermore, organizations with strong cybersecurity frameworks report a decrease in incident response time by as much as 40%, further contributing to sustained productivity and enhanced decision-making processes within industrial operations. By prioritizing security, industries not only safeguard their assets but also pave the way for improved efficiency and competitiveness in a fast-evolving market.

This chart illustrates the impact of enhanced security features on the efficiency of various industrial control systems. The data showcases the percentage increase in operational efficiency following the implementation of advanced security measures.

Advanced control technologies play a pivotal role in enhancing the efficiency of industrial control systems. By implementing real-time monitoring and automation, organizations can significantly reduce operational costs and improve output quality. According to a report by the International Society of Automation (ISA), the integration of advanced control systems can lead to efficiency improvements of up to 20%. These systems utilize data analytics and machine learning algorithms to optimize processes, enabling manufacturers to respond swiftly to market demands while minimizing waste and resource consumption.

Moreover, the rise of the Industrial Internet of Things (IIoT) has ushered in a new era of connectivity and data-driven decision-making. A study by McKinsey reveals that industries adopting IIoT-enabled control systems could see productivity gains range from 10% to 30% over the next decade. This interconnectivity allows for predictive maintenance and real-time adjustments, ensuring that machinery operates at peak performance. By leveraging these advanced technologies, companies are not only enhancing their operational efficiency but also reinforcing their competitive advantage in a rapidly evolving market landscape.

The integration of IoT in modern industrial control systems has revolutionized the way industries operate, providing enhanced security and efficiency. By leveraging IoT technology, businesses can now collect real-time data from various sensors and devices within their operations. This data-driven approach allows for better monitoring and control of industrial processes, leading to optimized performance and minimized downtime. Furthermore, IoT-enabled systems facilitate predictive maintenance, reducing operational costs and extending the lifespan of machinery.

Tips: To maximize the advantages of IoT integration, companies should prioritize data security from the outset. Implementing robust cybersecurity measures, such as regular software updates and employee training, can significantly mitigate risks associated with potential cyber threats. Additionally, choosing the right IoT infrastructure that supports seamless communication between devices will ensure that data flows smoothly, allowing for timely decision-making.

Moreover, as industries continue to evolve, the need for interoperability among devices becomes crucial. An effective strategy involves selecting compatible IoT components that can work together within various control systems. This not only enhances efficiency but also simplifies integration processes, ultimately leading to a more cohesive operational framework. By prioritizing these aspects, organizations can harness the full potential of IoT in their industrial control systems.

The landscape of industrial control systems (ICS) is undergoing a significant transformation driven by advancements in technology and an increasing focus on resilience. As organizations strive to bolster their operational robustness, trends are emerging that prioritize security and efficiency. According to the latest Industry Cybersecurity Report, over 60% of ICS professionals foresee the integration of artificial intelligence and machine learning in their systems by 2025, helping to enhance predictive maintenance and anomaly detection. This strategic integration not only helps mitigate risks but also contributes substantially to overall operational efficiency.

Moreover, with the rise of the Internet of Things (IoT) in industrial environments, the standardization of communication protocols is expected to enhance interoperability among systems. A report from the International Society of Automation indicates that by 2024, organizations implementing standardized protocols can achieve up to a 30% reduction in system downtime. This shift towards greater resilience ensures that companies can respond more effectively to both cyber threats and operational disruptions, leading to a more agile and responsive industrial framework. As these trends evolve, it is clear that the future of ICS will be characterized by a balance of security and efficiency, paving the way for smarter industrial operations.