In the rapidly evolving landscape of industrial automation, mastering your PLC control system is crucial for optimizing performance and enhancing efficiency. Whether you are a seasoned engineer or a newcomer to the field, understanding the intricacies of your control system can significantly impact your operations.

This blog post presents ten essential tips designed to help you navigate the complexities of PLC programming and troubleshooting. From effective debugging techniques to maximizing the use of available resources, these insights will empower you to harness the full potential of your PLC control system.

By implementing these strategies, you can improve system reliability, ensure seamless integration with other technologies, and ultimately drive greater productivity in your operations. Join us as we delve into the key practices that will elevate your skills and confidence in managing PLC systems.

Programmable Logic Controllers (PLCs) have revolutionized industrial automation, acting as the backbone of modern control systems. As per a recent report from Markets and Markets, the global PLC market is projected to reach USD 11.7 billion by 2025, growing at a CAGR of 6.0%. This growth highlights the increasing reliance on PLCs across various sectors, from manufacturing to process control, emphasizing their crucial role in enhancing efficiency and reliability.

Understanding the basics of PLC control systems is paramount for anyone involved in automation. A PLC operates by receiving input signals from sensors, processing these inputs through its programmed logic, and generating output signals to control machinery. According to a study by Grand View Research, the incorporation of PLCs can lead to a 20% reduction in operational costs and improve response times by up to 50%. These systems not only streamline operations but also provide flexibility for modifications, allowing businesses to adapt quickly to changing production requirements, a vital trait in today’s fast-paced industrial landscape.

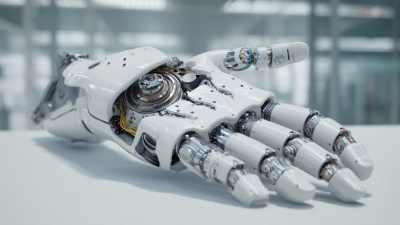

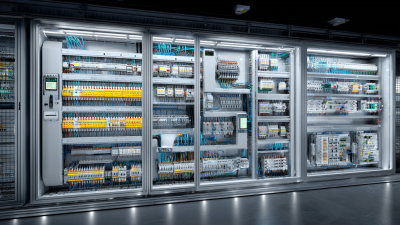

Understanding the key components of a PLC (Programmable Logic Controller) system is crucial for anyone looking to master automation in industrial settings. A PLC primarily consists of the central processing unit (CPU), input/output (I/O) modules, and power supply. The CPU acts as the brain of the system, interpreting inputs and executing control commands based on the programmed logic. This makes it essential to choose a reliable CPU that can handle the expected workload and speed of operations in your specific application.

The I/O modules are another critical aspect of PLC systems. They facilitate communication between the CPU and external devices such as sensors, actuators, and machines. Understanding the different types of I/O modules, including digital and analog, is important for effective system integration. Additionally, the power supply ensures that all components operate smoothly, providing the necessary voltage and current. Knowing how to select and maintain these components can significantly impact the efficiency and reliability of your PLC control system, enabling you to optimize automation processes and troubleshoot more effectively.

The following bar chart shows the key components of PLC systems and their relative importance based on user experience and feedback. Mastering these components is essential for effective PLC programming and operation.

In the current landscape of programmable logic controller (PLC) programming, selecting the right programming language is crucial for optimizing automation systems. According to the IEC 61131-3 standard, which defines multiple languages including Ladder Diagram (LD) and Structured Text (ST), the choice of language depends heavily on specific application requirements and user skill sets. Recent trends indicate a significant shift towards the adoption of scripted programming languages within newer PLC systems, moving away from traditional ladder logic. This evolution points to a growing preference for flexibility and ease of integration with modern development environments.

Industry experts highlight that although traditional languages like LD remain popular, there is a compelling argument for multi-language programming strategies that incorporate Structured Text and Function Block Diagram (FBD). These languages can offer improved functionality and efficiency. Low-code platforms are also gaining traction, allowing users with varying levels of programming experience to develop and maintain PLC applications more easily. As automation grows increasingly complex, the role of AI-assisted coding tools is becoming more prominent, further supporting the need for diverse programming language capabilities in PLC development. The ongoing transition signifies an exciting period for industrial automation, where the right programming language can unlock immense potential for productivity and innovation.

Troubleshooting PLC control issues can be a complex task, but following some essential strategies can significantly simplify the process. Identifying common problems quickly is crucial. For instance, issues like unexpected output behavior or communication failures often stem from wiring problems or incorrect programming logic. Always ensure connections are secure and verify your code against logical errors.

When it comes to optimizing PLC (Programmable Logic Controller) systems for industrial automation, enhancing efficiency and reliability is paramount. According to a report by the International Society of Automation, integrating best practices in PLC management can lead to a reduction in system downtime by up to 30%. This reduction not only saves costs but also significantly improves overall productivity on the factory floor.

One of the key strategies for improving PLC efficiency is regular maintenance and updates. A study by ARC Advisory Group highlights that organizations that implement routine maintenance schedules for their PLCs can experience a 20% increase in operational reliability. Furthermore, adopting advanced monitoring tools can provide real-time insights into system performance, allowing for proactive adjustments and minimizing delays caused by unexpected failures. Ensuring that your programming is optimized—such as avoiding redundant instructions and using efficient algorithms—also plays a vital role in maximizing the performance of PLC systems. By focusing on these best practices, businesses can achieve a more robust and reliable PLC control system, ultimately driving greater operational success.