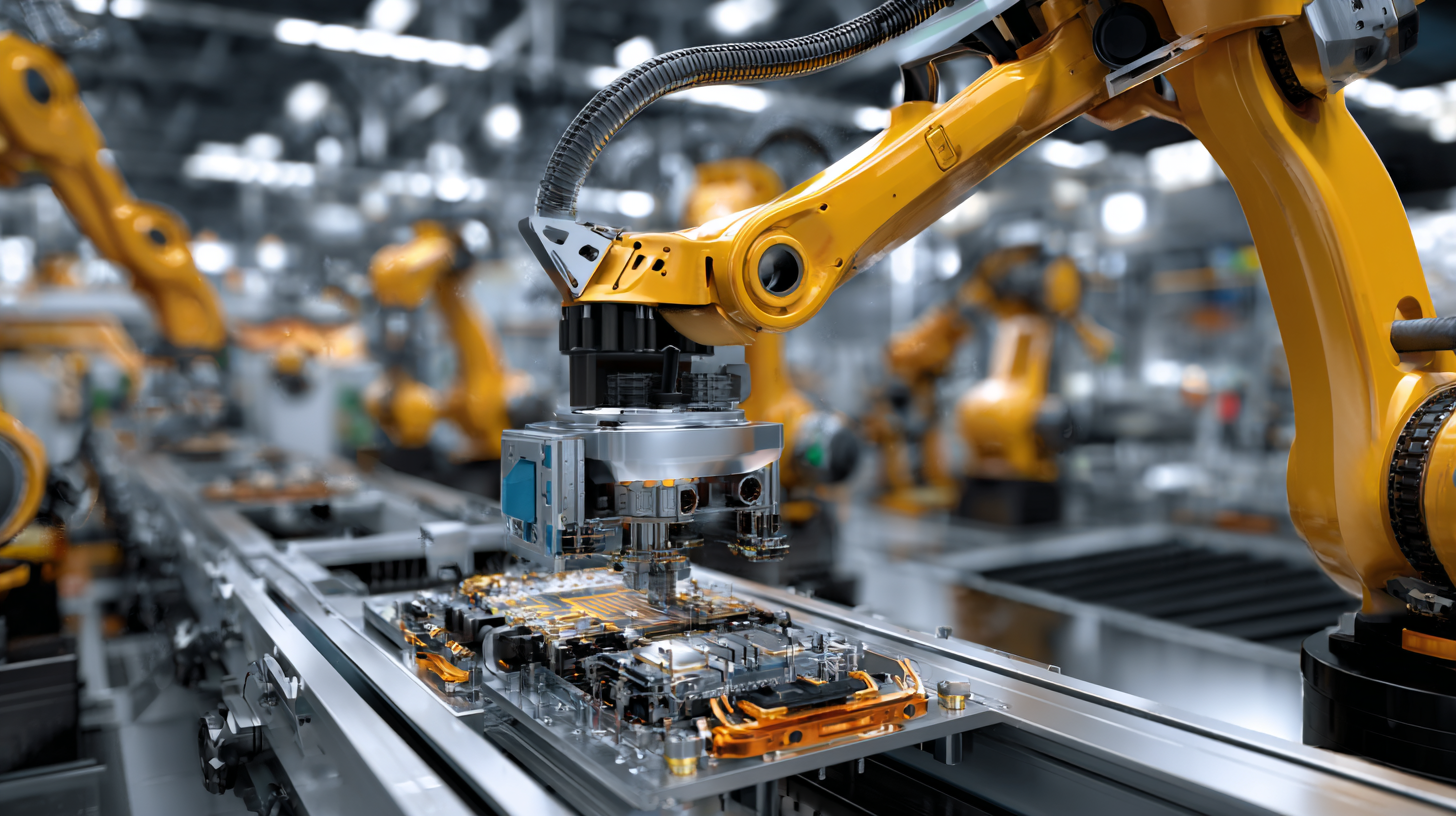

In today's rapidly evolving industrial landscape, the term "World Industrial Automation" signifies not just a trend but a transformative force shaping the future of manufacturing and production processes globally. As industries strive for increased efficiency, reduced costs, and enhanced precision, the integration of automation technologies becomes imperative. This comprehensive guide is designed to navigate you through the multifaceted realm of industrial automation solutions. From the latest innovations in robotics and artificial intelligence to the importance of data analytics and IoT, we will provide valuable insights and practical tips that can empower businesses to leverage these advancements effectively. Whether you are a seasoned professional or just entering the field, understanding the nuances of world industrial automation will equip you with the tools necessary to thrive in a competitive market. Join us as we explore the strategies, challenges, and opportunities that lie ahead in the journey toward automated excellence.

Industrial automation refers to the use of control systems such as computers or robots for handling different processes and equipment in industries, allowing for improved efficiency and accuracy. The significance of industrial automation has been underscored by a report from Markets and Markets, predicting that the global industrial automation market is set to reach USD 296.70 billion by 2026, growing at a CAGR of 8.3% from 2021. This growth is primarily driven by the need for increased productivity, safety, and reduced operational costs across various sectors.

Understanding the fundamentals of industrial automation is crucial as it encompasses various technologies, including robotics, machine learning, and the Internet of Things (IoT). According to a study by McKinsey, implementing automation can improve operational performance by up to 30% in manufacturing processes. Furthermore, with the increasing need for the smart factories of the future, industries are investing in automation solutions that not only streamline production but also enhance product quality and reduce waste. As companies embrace these innovations, the importance of understanding industrial automation expands, marking it as a pivotal element for competitiveness in the global market.

| Aspect | Description | Benefits |

|---|---|---|

| What is Industrial Automation? | The use of control systems for operating equipment in manufacturing, facilities, boiler systems, and heat treating. | Reduces labor costs and human error. |

| Components of Automation | Includes sensors, controllers, actuators, and software. | Increases efficiency and precision in operations. |

| Types of Automation | Fixed, Programmable, and Flexible automation. | Provides flexibility and scalability for production processes. |

| Importance of Industrial Automation | Improves safety, efficiency, and product quality. | Enhances competitiveness in the market. |

| Industry Applications | Used in automotive, food and beverage, electronics, and pharmaceuticals. | Optimizes production lines and minimizes downtime. |

As the global industrial landscape evolves, understanding key components of industrial automation systems becomes crucial. These systems integrate various technologies and applications designed to enhance efficiency and productivity in manufacturing and other sectors. A significant aspect of this automation is the technology that enables simultaneous power and data transmission over Ethernet networks. Essential components, such as Power Supply Equipment (PSE) controllers and Industrial Control Systems (ICS), play a critical role in ensuring effective operation.

Tip: When evaluating automation solutions, consider the scalability of the components. Investing in modular systems can help you adapt to changing demands and minimize downtime as your operations grow.

The rise of Edge AI technology is transforming automation by processing data closer to the source, which enhances response times and operational insights. Key elements include processors, memory, and sensors designed to support AI applications. This shift not only optimizes performance but also allows businesses to harness real-time analytics for better decision-making.

Tip: Stay updated on the latest advancements in Edge AI technology. Integrating cutting-edge hardware can provide your business with a competitive advantage in the evolving industrial landscape.

When it comes to choosing the right industrial automation solution, understanding the various types available is crucial.

Goods-To-Person technologies (GTP) streamline warehouse operations by reducing the distance workers must travel to pick items, enhancing efficiency.

Meanwhile, Pick-To-Light systems simplify order fulfillment by directing workers to the items they need through visual prompts, which effectively minimizes errors and accelerates processing times.

These solutions are just a few examples of how automation can cater to different operational needs.

Goods-To-Person technologies (GTP) streamline warehouse operations by reducing the distance workers must travel to pick items, enhancing efficiency.

Meanwhile, Pick-To-Light systems simplify order fulfillment by directing workers to the items they need through visual prompts, which effectively minimizes errors and accelerates processing times.

These solutions are just a few examples of how automation can cater to different operational needs.

Tip: When evaluating automation solutions, consider conducting a thorough needs assessment within your organization. Determine the specific challenges you face and identify which technologies align best with your goals. This will help you make informed decisions that drive efficiency and growth.

Another important aspect to consider is the integration of advanced technologies, such as artificial intelligence (AI), into your automation strategy. AI can enhance predictive maintenance and process optimization, ultimately leading to significant cost savings and improved operational efficiency. However, ethical considerations must also be prioritized to ensure that automation technologies are implemented responsibly.

Tip: Stay updated on emerging trends and technologies in industrial automation. Participating in industry forums or workshops can provide valuable insights and help you understand how to leverage these advancements effectively for your business.

As industries evolve, the landscape of industrial automation is being profoundly transformed by emerging trends and innovations. One of the most significant movements is the integration of Artificial Intelligence (AI) and machine learning into automated systems. These technologies enable machines to learn from data, adapt to changes in real-time, and optimize operations without human intervention. This not only boosts efficiency but also reduces downtime, allowing companies to respond quickly to market demands.

Another critical trend is the rise of the Internet of Things (IoT) in industrial settings. IoT connects devices, enabling seamless communication and data exchange between machines and systems. This interconnectedness provides manufacturers with valuable insights into their operations, enhancing decision-making processes. With predictive maintenance capabilities, businesses can anticipate equipment failures, minimize costly repairs, and ensure continuous production. Moreover, the shift toward cloud-based automation solutions is facilitating unprecedented scalability and flexibility, allowing organizations to adapt rapidly to the changing industrial environment.

Collaborative robots, or cobots, are also shaping the future of industrial automation by working alongside human operators. These robots are designed to share tasks, increase productivity, and improve workplace safety. With advancements in sensor technology and AI, cobots are becoming more intuitive, learning from their human counterparts and adjusting their actions accordingly. This not only enhances operational efficiency but also fosters a more harmonious workplace where technology and human innovation go hand in hand. As these trends continue to unfold, they promise a dynamic future for industrial automation.

Choosing the right industrial automation partner is crucial for businesses aiming to leverage advanced technologies effectively. With the rapid evolution of AI and robotics, it’s essential to evaluate potential partners not only based on their technological capabilities but also on their market influence and specialization. Companies today should prioritize those that demonstrate a robust product portfolio and an innovative approach to automation challenges. This could involve assessing their experience in specific industries or their ability to customize solutions that fit unique operational needs.

Moreover, as artificial intelligence becomes intertwined with automation solutions, aligning with partners that have a solid AI strategy can provide significant advantages. Businesses should look for partners who understand the complexities of AI implementation, ensuring they can offer support throughout the integration process. Key considerations should include their methodologies for AI deployment, past success stories, and their capacity to adapt to continuous advancements in technology. By carefully evaluating these factors, companies can forge partnerships that not only enhance operational efficiency but also drive long-term growth in an increasingly automated industrial landscape.