In the rapidly evolving landscape of modern manufacturing, the integration of advanced technology is paramount to enhancing operational efficiency and product quality. One such integral technology is the DCS Control System (Distributed Control System), which has become increasingly vital for manufacturers aiming to streamline processes and ensure optimal performance. According to the latest Industry Research report, the global DCS market is projected to reach $23.93 billion by 2027, growing at a CAGR of 7.5% from 2020 to 2027. This underscores the critical role that DCS Control Systems play in facilitating real-time monitoring, redundancy, and centralized data management, which are essential for maintaining competitiveness in today's market. Understanding the importance of DCS Control Systems not only empowers manufacturers to harness these efficiencies but also positions them to adapt to the dynamic demands of production environments.

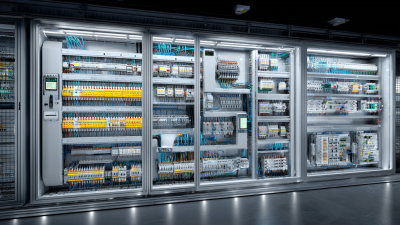

In the dynamic landscape of modern manufacturing, the Distributed Control System (DCS) plays a pivotal role in streamlining processes. By integrating various control functions, DCS systems facilitate real-time monitoring and management of production processes, leading to enhanced efficiency and productivity. The ability to control multiple processes from a centralized location allows operators to respond quickly to deviations or anomalies, minimizing downtime and optimizing resource utilization.

Moreover, DCS enhances collaboration across different departments within manufacturing operations. It enables seamless communication between production, quality assurance, and maintenance teams, ensuring that all stakeholders are aligned and informed. This cohesive approach not only reduces operational silos but also fosters a culture of continuous improvement. With advanced data analytics and reporting capabilities, DCS systems provide valuable insights into production performance, empowering decision-makers to make data-driven choices that further streamline processes and elevate overall operational effectiveness.

In the realm of modern manufacturing, the implementation of Distributed Control Systems (DCS) has become increasingly essential, particularly in sectors like energy. DCS control systems offer a high level of automation and flexibility, enabling organizations to manage complex processes with improved efficiency. One key benefit of integrating DCS is the enhanced ability to monitor operations in real time, providing critical data that supports informed decision-making. This capability leads to reduced downtime and higher productivity, essential for staying competitive in today’s fast-paced market.

Moreover, DCS systems contribute to safety and compliance in manufacturing environments. With advanced features such as alarm management and automatic fault detection, they minimize the risk of human error, ensuring that systems operate smoothly. In the energy sector, particularly in electric power transmission and distribution, the practical application of modern DCS can dramatically improve operational reliability. By streamlining processes and optimizing resource allocation, organizations can not only enhance their output but also drive sustainable practices that are increasingly important in today’s economic landscape.

In the realm of modern manufacturing, the Distributed Control System (DCS) plays a pivotal role in enhancing data collection and real-time monitoring. By integrating various components across the production process, DCS enables manufacturers to gather vast amounts of data from different operational points. This capability allows for a comprehensive understanding of the manufacturing environment, enabling companies to make informed decisions quickly and efficiently.

Real-time monitoring facilitated by DCS provides manufacturers with instant access to critical operational data. This not only aids in detecting anomalies or potential issues before they escalate but also optimizes overall process efficiency. With the ability to analyze data as it flows in, manufacturers can identify trends, allocate resources more effectively, and enhance productivity. The seamless integration of technology within DCS ensures that businesses remain agile, adapting swiftly to changing market demands while maintaining reliability and safety in operations.

In modern manufacturing, the integration of Distributed Control Systems (DCS) with existing technologies is vital for streamlined operations and enhanced productivity. According to a report by Markets and Markets, the DCS market is expected to grow from USD 18.8 billion in 2022 to USD 28.6 billion by 2027, reflecting a compound annual growth rate (CAGR) of 8.5%. This growth signifies that more manufacturers are recognizing the need for sophisticated control systems that can seamlessly interface with legacy systems, improving not only process control but also data interoperability.

The integration of DCS facilitates the application of advanced analytics and real-time data processing, which can lead to more informed decision-making. A study by Frost & Sullivan highlights that companies employing DCS integrations have reported up to a 20% improvement in operational efficiency. By connecting DCS with existing SCADA systems and IoT infrastructures, manufacturers can achieve a holistic view of their operations, enabling predictive maintenance and reducing downtime. This integration not only provides greater control but also fosters an agile production environment, which is crucial in today’s fast-paced market.

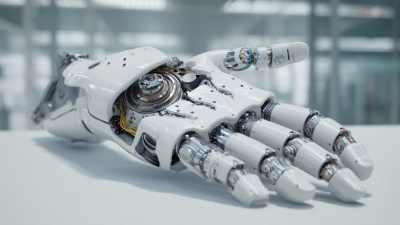

The future of Distributed Control Systems (DCS) in manufacturing is brighter than ever, driven by advancements in technology and the persistent demand for improved efficiency. Emerging trends such as the integration of artificial intelligence and the Internet of Things (IoT) promise to revolutionize traditional control systems. By leveraging real-time data analytics, manufacturers can achieve higher levels of automation, predictive maintenance, and enhanced process optimization. This not only minimizes downtime but also leads to significant cost savings and improved product quality.

Tips for implementing DCS advancements include investing in training for personnel to adapt to new technologies, ensuring robust cybersecurity measures as systems become increasingly interconnected, and regularly reviewing system performance metrics to identify areas for improvement. Additionally, collaborating with technology providers can aid manufacturers in customizing solutions that fit specific operational needs.

As DCS continues to evolve, the adoption of smart sensors and machine learning algorithms will enable predictive analytics, allowing for timely interventions and adaptive control strategies. Keeping an eye on these trends will be essential for manufacturers looking to stay competitive in a fast-paced market. Implementing these technologies can transform manufacturing processes, leading to a more agile and responsive production environment.

| DCS Feature | Current Impact | Future Trends | Impact on Efficiency |

|---|---|---|---|

| Real-time Monitoring | Enhances decision-making and reduces downtime | Integration with IoT devices | Increases operational efficiency by 20% |

| Automated Controls | Reduces human error and improves productivity | AI and machine learning advancements | Potential productivity boost by 15% |

| Data Analytics | Facilitates predictive maintenance | Advanced analytical tools and algorithms | Improves equipment uptime by 30% |

| Scalability | Easy to expand operations | Cloud-based DCS solutions | Enhances growth capacity by 25% |

| Security Features | Protects against cybersecurity threats | Enhanced cybersecurity measures | Reduces risk of operational disruption |