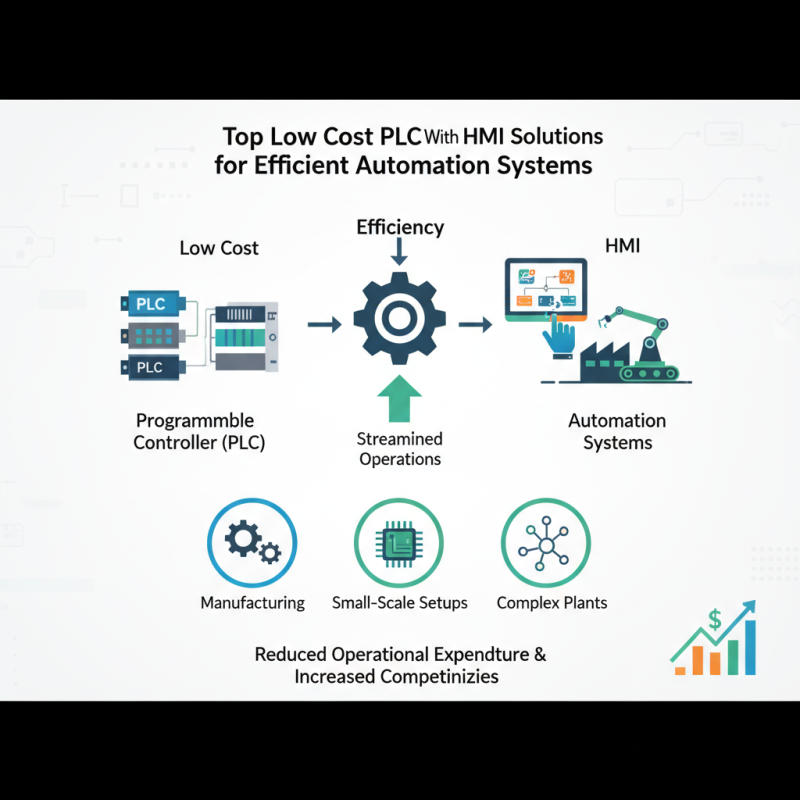

In the ever-evolving landscape of industrial automation, achieving efficiency while minimizing costs has become a paramount concern for businesses globally. One effective approach to address this challenge is the integration of Low Cost PLC With HMI solutions. These systems not only facilitate streamlined operations but also provide intuitive interfaces that enhance user interaction and control over automated processes. As organizations strive to optimize their production environments, the selection of cost-effective programmable logic controllers (PLCs) combined with user-friendly human-machine interfaces (HMIs) plays a critical role in driving productivity and reducing operational expenditure.

Furthermore, the versatility of Low Cost PLC With HMI solutions makes them suitable for a wide range of applications across different industries. From small-scale manufacturing setups to more complex automated plants, these systems offer scalable solutions that can adapt to the needs of any organization. This adaptability ensures that businesses can implement automation technologies without the burden of prohibitive costs, ultimately paving the way for increased competitiveness in a challenging market. As we delve into the details of these innovative solutions, it becomes evident that they not only represent a viable option for cost-conscious enterprises but also serve as a foundation for future advancements in automation technology.

In recent years, low-cost programmable logic controllers (PLCs) have emerged as pivotal components in the realm of automation systems, offering cost-effective solutions without compromising on functionality. According to a report by MarketsandMarkets, the global PLC market is expected to grow from USD 8.5 billion in 2021 to USD 12.8 billion by 2026, reflecting a CAGR of 8.5%. This growth underscores the rising demand for automation across various industries, where low-cost PLCs serve as accessible entry points for companies looking to implement efficient and scalable automation processes.

Low-cost PLCs are particularly appealing for small and medium enterprises (SMEs) that require reliable automation without substantial financial investment. These PLCs typically come with integrated Human-Machine Interfaces (HMIs), which enable users to monitor and control processes seamlessly. A study from IBISWorld highlights that automation can increase production efficiency by up to 30%, illustrating the tangible benefits that SMEs can reap through the deployment of economical automation solutions. Moreover, the intuitive design of many low-cost PLCs allows for reduced setup times and lower training costs, making them an attractive option for businesses striving for quick returns on investment while enhancing operational efficiency.

| PLC Model | HMI Compatibility | Input/Output Points | Communication Protocols | Approx. Price ($) |

|---|---|---|---|---|

| PLC-A | Yes | 16 I/O | Modbus, Ethernet | 200 |

| PLC-B | Yes | 32 I/O | Profibus, RS-232 | 250 |

| PLC-C | No | 24 I/O | Ethernet, Serial | 150 |

| PLC-D | Yes | 40 I/O | CANopen, RS-485 | 300 |

| PLC-E | Yes | 64 I/O | EtherCAT, USB | 450 |

In today’s industrial landscape, Human-Machine Interface (HMI) solutions play a pivotal role in enhancing user interaction within automation systems. According to a MarketsandMarkets report, the HMI market is anticipated to grow from $4.73 billion in 2020 to $6.84 billion by 2025, demonstrating a strong annual growth rate of 7.8%. This expansion underscores the importance of integrating advanced HMI features to facilitate efficient communication between operators and machines.

One of the key features of modern HMI solutions is their ability to provide real-time data visualization. This capability allows operators to monitor system performance effectively, leading to quicker decision-making and improved operational efficiency. Furthermore, intuitive touch screens and customizable dashboards enhance user engagement, reducing training time for new personnel. A study by Research and Markets indicates that well-designed HMI systems can improve productivity by up to 20%, highlighting the significant impact these tools have on overall automation efficiency.

Another notable aspect of HMI solutions is their support for connectivity and integration with various PLCs and other devices. With the rise of Industry 4.0, the need for seamless data exchange across multiple platforms is paramount. By incorporating features such as remote access and cloud integration, these solutions ensure that users have the necessary tools for effective oversight and management of automation systems. Industry reports suggest that implementing advanced HMI functionalities can significantly reduce downtime, increase safety, and enhance the overall user experience in complex automation environments.

Integrating Programmable Logic Controllers (PLC) with Human-Machine Interfaces (HMI) creates a powerhouse for efficient automation systems. The combination allows for seamless interaction between humans and machines, providing operators with real-time insights into system performance. With a well-designed HMI, users can easily monitor processes, set parameters, and receive alerts on system status, which significantly enhances operational efficiency. This integration simplifies complex processes, enabling even non-technical personnel to effectively manage automation systems.

Tips: When selecting a PLC and HMI solution, consider the ease of use and the adaptability of the interface. An intuitive design can drastically reduce training time and help ensure that personnel can quickly respond to system events. Additionally, aim for scalable solutions that can grow with your operational demands, maintaining efficiency as your needs evolve.

The integration of PLC and HMI also contributes to improved troubleshooting capabilities. With detailed graphical representation and user-friendly controls, operators can quickly identify and address issues, minimizing downtime. Moreover, this unified approach allows for better data collection and analysis, driving continuous improvement. Investing in these technologies not only boosts productivity but also ensures a more robust safety framework within automation systems.

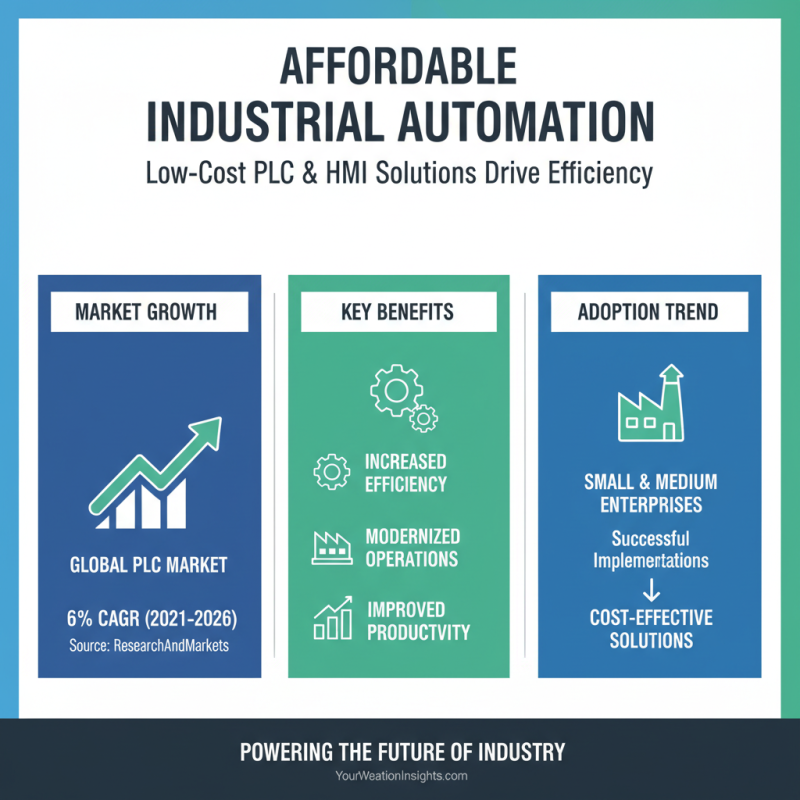

In today’s rapidly evolving industrial landscape, organizations are increasingly turning to low-cost PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) solutions to enhance automation efficiency. A report by ResearchAndMarkets estimates that the global PLC market is expected to grow at a CAGR of over 6% from 2021 to 2026, indicating a strong shift towards affordable automation technologies. Numerous case studies illustrate how small to medium-sized enterprises have successfully implemented these cost-effective solutions to modernize their operations and improve productivity.

One compelling case involved a manufacturing plant that replaced its outdated automation system with low-cost PLCs and HMIs, resulting in a 30% reduction in operational downtime. By integrating these technologies, the facility achieved real-time monitoring and streamlined production processes. According to a study by the International Society of Automation, companies that implement such inexpensive automation solutions report up to a 25% increase in operational efficiency. These examples highlight the potential for low-cost automation to revolutionize processes across various sectors, enabling even smaller firms to compete in a technology-driven market.

Another case study from a food processing facility emphasized the return on investment from switching to affordable PLC and HMI solutions. The plant experienced improvements in quality control and production speed, realizing a payback period of less than one year. The data suggests that low-cost automation can deliver not just efficiency gains but also significant financial benefits, making a compelling case for its adoption in industries previously hesitant due to budget constraints. As such, low-cost PLC and HMI solutions are not merely an alternative but a strategic choice for organizations aiming to enhance their automation capabilities and thrive in a competitive environment.

The landscape of affordable PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) technologies is evolving rapidly, driven by innovations in automation and increasing demands for efficiency. Future trends indicate a significant shift towards more integrated and user-friendly systems that offer high performance without steep costs. As manufacturers prioritize the development of cost-effective solutions, features such as cloud connectivity, advanced data analytics, and intuitive interfaces are becoming common, allowing users to leverage real-time information for informed decision-making.

Moreover, the rise of Internet of Things (IoT) technology is set to redefine the dynamics of PLC and HMI solutions. The integration of IoT capabilities enables devices to communicate seamlessly, fostering an environment where automation systems can be monitored and controlled remotely. This connectivity not only enhances operational efficiency but also facilitates predictive maintenance, dramatically reducing downtime and maintenance costs. As the trend towards smart automation systems continues, the demand for low-cost, high-performance PLC and HMI solutions will only grow, empowering businesses, regardless of size, to embrace advanced automation technologies that were once beyond their reach.