In the rapidly evolving landscape of industrial automation, maximizing efficiency is paramount for organizations seeking to thrive in the digital age. Siemens Plc has emerged as a leader in providing innovative solutions that facilitate digital transformation across industries. According to a recent report by McKinsey & Company, companies that implement digital transformation strategies can increase their productivity by up to 30%. Moreover, the World Economic Forum predicts that integrating advanced technologies like IoT and AI into manufacturing processes could unlock trillions in economic value by 2030. By leveraging Siemens Plc's cutting-edge technology and methodologies, businesses can streamline operations, enhance decision-making, and ultimately drive greater profitability. This blog will present a comprehensive checklist aimed at ensuring a successful digital transformation journey, empowering organizations to harness the full potential of Siemens Plc's offerings.

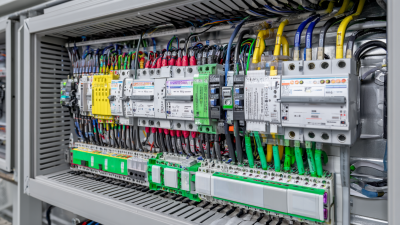

Digital transformation is reshaping industries, and Siemens PLC plays a crucial role in this evolution. Siemens PLCs bring advanced automation and data processing capabilities to various sectors, enabling seamless integration of digital technologies into operational workflows. By employing Siemens PLCs, companies can enhance their production efficiency, reduce downtime, and improve overall responsiveness to market changes.

To maximize the benefits of Siemens PLC in your digital transformation strategy, consider implementing these tips. First, invest in training your workforce to ensure they are skilled in operating and maintaining Siemens PLC systems. A knowledgeable team can significantly reduce errors and maximize productivity. Second, utilize Siemens’ advanced analytics features to monitor system performance in real-time, allowing for proactive maintenance and quicker decision-making processes. Lastly, foster a culture of continuous improvement by regularly assessing your PLC configurations and updating them to leverage new functionalities and tools available within the Siemens ecosystem.

By strategically utilizing Siemens PLC technology, businesses not only streamline their processes but also lay a solid foundation for future innovations and advancements in their digital transformation journey.

In today's fast-paced manufacturing landscape, digital transformation is vital for staying competitive. Implementing Siemens PLC (Programmable Logic Controllers) effectively can significantly enhance operational efficiency. According to a recent report by McKinsey, companies that successfully integrate digital technologies into their operations can increase productivity by up to 25%. This statistic underscores the importance of adopting Siemens PLC systems in modern manufacturing environments.

One of the key strategies for implementing Siemens PLC is thorough training and continuous skill development for your workforce. Empowering employees with the right knowledge ensures they can leverage PLC capabilities to their fullest potential. On average, organizations that invest in training programs report a 15% increase in overall productivity. Another tip is to start small; piloting Siemens PLC in a single plant or production line can provide valuable insights and allow for the refinement of processes before broader deployment.

Furthermore, integration with existing systems is crucial. Ensure that your Siemens PLC can communicate seamlessly with other technologies in your facility, such as MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) systems. A study by IDC indicated that organizations optimizing their technology stack see up to a 30% reduction in operational costs. By following these strategies, manufacturers can maximize the benefits of Siemens PLC, driving successful digital transformation and sustaining competitive advantages.

In today's rapidly evolving industrial landscape, enhancing operational efficiency is paramount for organizations aiming for sustainable growth. Siemens PLC automation offers cutting-edge solutions that not only streamline processes but also bolster productivity. According to a recent report by McKinsey, companies that invest in automation can increase their productivity by up to 30%. Siemens' innovation in process automation and control systems empowers businesses to implement smart manufacturing techniques that minimize downtime and optimize resource allocation.

To maximize the benefits of Siemens PLC in your operations, consider the following tips. First, invest in comprehensive training for your staff to ensure they can effectively operate and troubleshoot the system. Research shows that organizations with well-trained personnel experience 25% fewer production errors. Additionally, integrate advanced data analytics to monitor performance in real time, providing insights that lead to informed decision-making. Lastly, don't overlook the importance of regular maintenance; a study by the American Society of Mechanical Engineers found that proactive maintenance can reduce operational costs by up to 20%.

Implementing these strategies through Siemens PLC automation not only enhances efficiency but also fosters a culture of continuous improvement, positioning your organization for long-term success in the digital age.

| Dimension | Description | Efficiency Improvement (%) | Implementation Time (Months) |

|---|---|---|---|

| Process Automation | Automating repetitive tasks to reduce manual errors. | 30% | 3 |

| Data Integration | Centralizing data for better decision-making. | 25% | 4 |

| Remote Monitoring | Tracking equipment performance in real-time. | 20% | 2 |

| Predictive Maintenance | Using data analytics to foresee maintenance needs. | 35% | 6 |

| Employee Training | Updating staff skills to work with new technologies. | 15% | 5 |

The integration of IoT with Siemens PLC offers unprecedented opportunities for businesses aiming to achieve smart solutions in their operations. According to a report by McKinsey, companies that adopt IoT technologies can improve their productivity by up to 30%, significantly enhancing operational efficiency. Siemens PLC, recognized for its robust automation capabilities, allows organizations to harness IoT data effectively, bridging the gap between digital and physical processes.

To maximize efficiency with Siemens PLC, consider implementing the following tips. First, ensure seamless connectivity by using Siemens’ SIMATIC IoT2040 gateway, which facilitates data flow from machines to the cloud with ease. Second, leverage advanced analytics tools available within the Siemens framework to extract actionable insights from IoT data, enabling real-time decision-making. Finally, prioritize cybersecurity measures as highlighted by industry experts; a recent report from Gartner indicates that 75% of IoT breaches stem from inadequate security protocols. By adopting these practices, businesses can fully unlock the potential of IoT integration with Siemens PLC, paving the way for smarter, more efficient operations.

This chart demonstrates the efficiency improvements in various sectors after the integration of IoT with PLC systems. The data highlights the percentage increase in efficiency across manufacturing, energy, and transportation industries.

Training teams on Siemens PLC capabilities is essential for ensuring a smooth digital transformation within manufacturing operations. According to a recent report by Deloitte, organizations that invest in comprehensive training programs see productivity increases of up to 20%. This highlights the importance of equipping your workforce not only with the knowledge of Siemens PLC systems but also with the skills to leverage these technologies for enhanced performance.

To maximize efficiency, consider implementing hands-on workshops that combine theory with practical applications. For instance, facilitating simulations of real-world scenarios where employees can troubleshoot and optimize Siemens PLCs can significantly deepen their understanding. Additionally, incorporating ongoing mentorship from experts within the field can ensure that team members maintain a continuous learning curve.

Another effective tip is to create a culture of knowledge sharing. Establishing internal forums or using collaborative tools allows team members to exchange best practices and solutions that they discover while working with Siemens PLC systems. According to McKinsey, organizations with a strong emphasis on knowledge sharing can achieve a 25% increase in team performance. By nurturing an environment of cooperation and open communication, you will empower your teams, leading to a more seamless digital transformation.