In today's fast-paced manufacturing landscape, companies are constantly seeking ways to enhance productivity and streamline operations. One of the most effective approaches to achieving these goals is through the implementation of PLC automation solutions. Programmable Logic Controllers (PLCs) offer robust capabilities that allow businesses to automate complex processes and improve overall efficiency. In this blog, we will explore top strategies for maximizing efficiency with PLC automation, highlighting best practices and innovative techniques that can transform your operations. By leveraging the power of PLC automation, organizations can not only reduce downtime and minimize errors but also drive significant cost savings. Join us as we delve into the world of PLC automation and uncover actionable insights that can elevate your manufacturing processes.

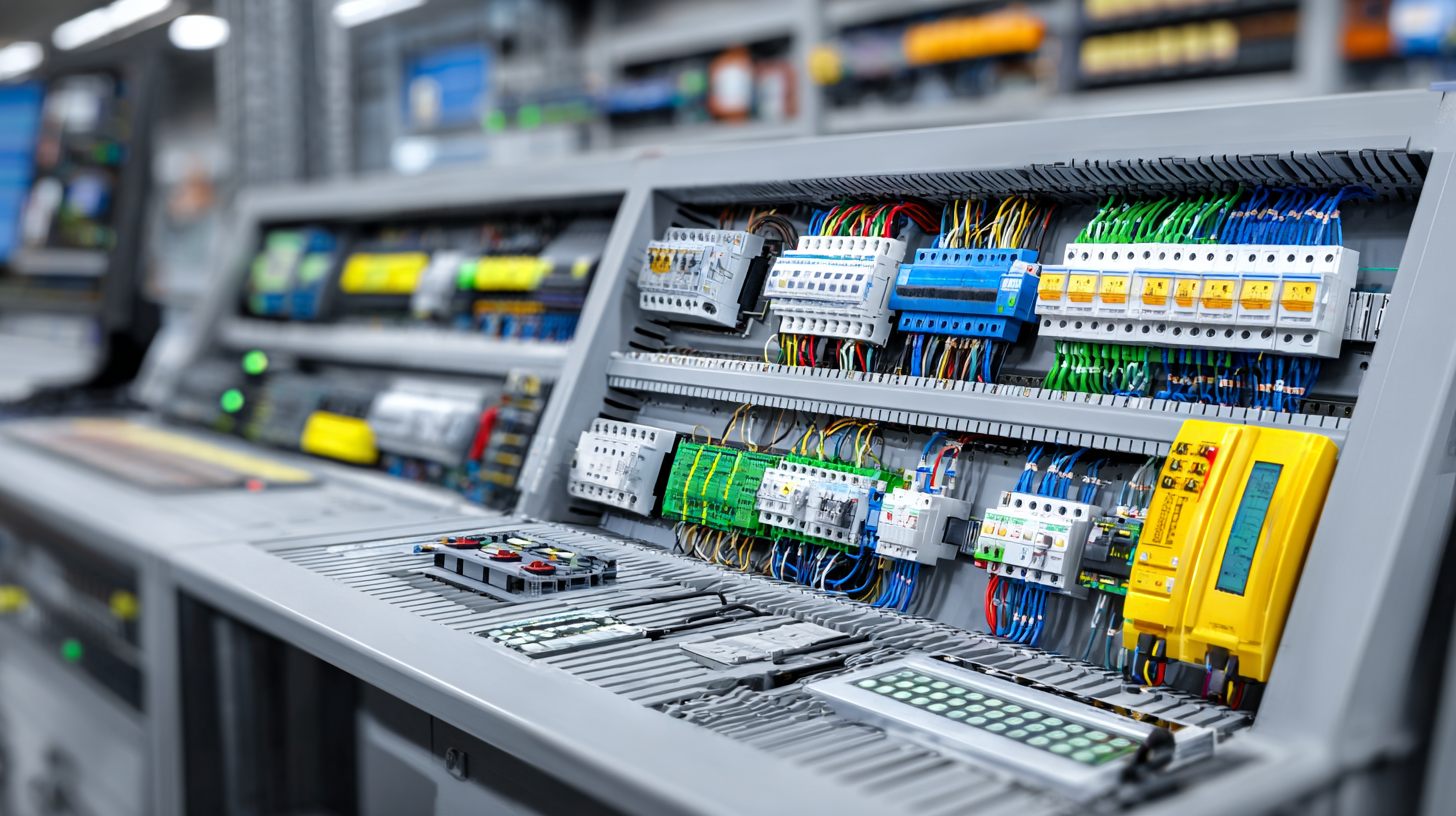

Programmable Logic Controllers (PLCs) are essential components in modern automation systems, enabling efficient control of machinery and processes. For those new to PLC automation, understanding key concepts is crucial for leveraging these powerful tools. PLCs operate by executing pre-programmed instructions to manage inputs and outputs, ensuring smooth operations in various industrial environments. Beginners should become familiar with basic components such as input/output modules, processors, and communication interfaces, as well as programming languages like Ladder Logic and Structured Text that allow for the automation of tasks.

As you delve deeper into PLC automation, exploring practical applications can further enhance your skills. Engaging in hands-on projects, such as simulating real-world scenarios or developing simple control systems using PLC software, helps reinforce theoretical knowledge. Resources such as instructional books and online tutorials can provide additional insights and guidance. Understanding the interaction between hardware and software in PLC systems is vital, paving the way for more complex automation solutions and maximizing operational efficiency in your projects.

This chart illustrates the efficiency improvement percentages for various PLC automation strategies implemented in manufacturing settings.

The integration of Programmable Logic Controllers (PLC) into automation systems is pivotal for enhancing operational efficiency. Central to these systems are essential components such as input/output modules, processors, and communication interfaces. According to industry reports, the market for automation tools is projected to experience a compound annual growth rate (CAGR) of approximately 5.37% from 2024 to 2031, underscoring the growing value of effective PLC systems in modern industrial applications.

Moreover, as organizations strive for lightweight and efficient solutions, advancements in technology such as RAG (Retrieval-Augmented Generation) systems have emerged. The recent launch of a lightweight framework designed to facilitate RAG system deployment reflects the need for tools that do not compromise performance while remaining easily manageable. This shift emphasizes that the essential components of PLC systems must not only support robust processing capabilities but also enable integration with emerging technologies, ensuring that industries are well-equipped to adapt to rapid technological changes.

In summary, embracing advanced PLC solutions and their critical components is crucial for businesses aiming to enhance productivity while navigating the evolving landscape of automation technologies. The convergence of traditional automation with innovative lightweight systems presents an opportunity to drive performance efficiency in various sectors.

| Component | Function | Efficiency Impact | Best Practices |

|---|---|---|---|

| PLC Controller | Processes input and output signals | Central to automation, enhances decision-making | Regular updates and programming optimizations |

| HMI (Human-Machine Interface) | User interaction with the automation system | Improved operator awareness and control | Intuitive design and training |

| I/O Modules | Interface between PLC and field devices | Critical for signal integrity and processing speed | Selection based on application requirements |

| Networking Components | Connects PLCs with other systems | Facilitates real-time data exchange | Implement robust network security measures |

| Power Supply | Provides energy to the PLC | Ensures reliable operation | Use uninterrupted power supply systems |

Effective programming of Programmable Logic Controllers (PLCs) is essential for optimizing workflow in automated environments. One key best practice is modular programming, which involves breaking down complex tasks into smaller, manageable functions. This approach not only enhances readability but also simplifies troubleshooting and maintenance. By implementing reusable code blocks, engineers can reduce redundancy and ensure consistency across multiple projects, thereby saving time and minimizing errors.

Another crucial strategy is the use of standardized naming conventions and commenting within the code. Clear and consistent naming helps in identifying functions and variables quickly, making it easier for other programmers to understand and modify the code when necessary. Adding descriptive comments clarifies the purpose and functionality of specific code segments, facilitating smoother transitions during handovers or collaborative projects. Implementing these practices can lead to increased productivity, reduced downtime, and improved reliability in PLC operations, ultimately enhancing overall system performance.

Incorporating simulation tools during the programming phase can also significantly improve efficiency. By testing code in a virtual environment before deployment, potential issues can be identified and resolved early, preventing costly disruptions in the production process. This proactive approach not only enhances the robustness of the automation solution but also accelerates the development timeline, allowing organizations to fully leverage their PLC systems to achieve peak performance.

Troubleshooting common PLC (Programmable Logic Controller) issues is essential for maintaining operational efficiency in automated environments. One major concern is communication failure, which can disrupt workflows and lead to costly downtime. Engineers can mitigate this by regularly monitoring network configurations and ensuring that all devices are correctly connected and configured. Establishing a consistent communication protocol can help identify issues promptly and restore functionality with minimal interruption.

Another common issue arises from sensor malfunctions, which can result in erroneous readings and unpredictable system behavior. Implementing a routine maintenance schedule that includes testing and calibrating sensors can significantly reduce these risks. When anomalies are detected, technicians should have a systematic approach to troubleshoot the system, including checking wiring integrity and sensor alignment. By addressing these common PLC issues proactively, organizations can enhance productivity and achieve better outcomes from their automation solutions, ensuring that operations run smoothly and efficiently.

The integration of PLC (Programmable Logic Controller) automation with IoT (Internet of Things) technologies is transforming the manufacturing landscape, enhancing productivity and efficiency. According to a recent report by MarketsandMarkets, the global Industrial IoT market is expected to grow from $74.3 billion in 2020 to $110.6 billion by 2025, demonstrating the increasing relevance of IoT in automating processes. PLCs serve as the backbone of industrial automation, and when paired with IoT, they provide real-time data analytics that allow companies to make informed decisions more quickly.

By incorporating IoT with PLC systems, businesses can achieve greater visibility into their operations, ensuring that resources are allocated effectively. For instance, a McKinsey report highlights that companies that implement smart automation can increase productivity by up to 30%. Real-time monitoring and predictive maintenance—enabled by IoT—help identify issues before they escalate, reducing downtime and significantly lowering operational costs. This synergy not only boosts throughput but also enhances operational agility, allowing manufacturers to respond swiftly to market demands.