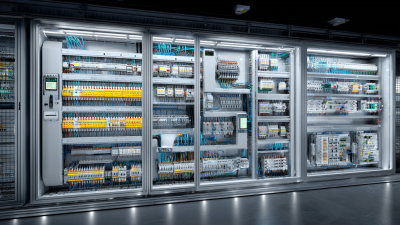

In today's rapidly evolving industrial landscape, optimizing your Distributed Control System (DCS) represents not only a technological enhancement but also a strategic necessity for organizations aiming for maximum efficiency. According to a report by MarketsandMarkets, the global Distributed Control Systems market is projected to grow from USD 18.26 billion in 2020 to USD 25.57 billion by 2025, reflecting an impressive compound annual growth rate (CAGR) of 7.2%. This increase underscores the need for industries to refine their DCS frameworks to leverage advanced functionalities, enhance responsiveness, and improve overall operational performance. Furthermore, the integration of modern technologies such as AI and IoT into DCS setups can significantly amplify efficiency and adaptability, allowing businesses to maintain a competitive edge. In this guide, we will delve into key strategies and best practices that can be employed to optimize your Distributed Control System, ensuring it operates at peak performance in a dynamic market environment.

In today's rapidly evolving industrial landscape, optimizing data communication in distributed control systems (DCS) is crucial for enhancing operational efficiency. A recent report by the International Society of Automation (ISA) indicates that inefficient data flows can lead to a decrease in system performance by up to 30%. To counter this, organizations must adopt robust communication strategies that reduce latency and improve data accuracy.

One effective approach is to implement high-speed network protocols, such as Time-Sensitive Networking (TSN) and MQTT, which can significantly enhance the responsiveness of DCS. Utilizing these protocols ensures that critical data is transmitted without delay, facilitating real-time monitoring and control. Additionally, consider segmenting networks to reduce congestion; according to an industrial analytics study, companies that segmented their networks saw a 25% increase in data throughput.

In the realm of distributed control systems (DCS), measuring efficiency is essential to ensure optimal performance and reliability. Key Performance Indicators (KPIs) serve as the yardstick for evaluating how effectively a system operates under varying conditions. Critical KPIs to consider include system throughput, response time, and fault recovery rate. Throughput measures the amount of work produced by the system in a given timeframe, while response time indicates how quickly the system reacts to changes in input. These two metrics directly impact operational reliability and user satisfaction.

Furthermore, monitoring fault recovery rate is crucial in assessing the robustness of the control environment. A high recovery rate signifies that the system can quickly restore functionality after a disruption, thereby minimizing downtime. Other important KPIs may include energy consumption per process, maintenance frequency, and overall system availability. By regularly analyzing these indicators, operators can make informed decisions about maintenance schedules, system upgrades, and resource allocation, ultimately driving greater efficiency and performance across the distributed control system.

Implementing predictive maintenance techniques in distributed control systems (DCS) can significantly reduce downtime and enhance reliability. According to a report by Aberdeen Group, companies that employ predictive maintenance strategies can reduce their operational costs by up to 30%. This proactive approach not only minimizes the risk of unexpected failures but also allows for optimized scheduling of maintenance activities, ensuring that critical systems remain operational when needed most.

One effective strategy is to leverage data analytics and machine learning algorithms to monitor equipment health in real-time. By analyzing historical performance data and identifying patterns, organizations can predict equipment failures before they occur. For instance, a study by McKinsey indicates that predictive maintenance cuts equipment failure rates by as much as 70%. This not only extends the lifespan of machinery but also provides substantial savings by avoiding costly emergency repairs.

Tips for implementing predictive maintenance effectively include starting with a thorough assessment of your current system to identify key assets that require monitoring, integrating IoT sensors for real-time data collection, and training your team on the use of predictive analytics tools. By engaging maintenance staff in the process, you can ensure a smoother transition to predictive maintenance, ultimately leading to improved system efficiency and reliability.

In today's rapidly evolving industrial landscape, the integration of advanced analytics into Distributed Control Systems (DCS) is revolutionizing real-time decision-making processes. By leveraging sophisticated data analysis techniques, organizations can gain deep insights into their operations, allowing them to make informed decisions swiftly. This transformation enhances not only operational efficiency but also drives responsiveness to changes in environmental conditions or system performance.

One of the key benefits of utilizing advanced analytics in DCS is the ability to predict and mitigate potential issues before they escalate. Through the implementation of machine learning algorithms and predictive maintenance strategies, facilities can monitor equipment health in real time, thereby reducing downtime and improving overall system reliability. Moreover, by analyzing historical performance data alongside real-time inputs, operators are equipped with actionable insights that facilitate optimal resource allocation and process adjustments, ensuring that production meets demand dynamically. This proactive approach sets the stage for a more resilient and optimized control system that adapts seamlessly to the complexities of modern production environments.

In today’s rapidly evolving industrial landscape, integrating IoT technologies into your distributed control system (DCS) can significantly streamline operations and enhance resource management. According to a recent report from McKinsey, companies that have adopted IoT solutions have seen a 30% reduction in operational costs, demonstrating the importance of embracing these technologies. By leveraging real-time data analytics and connectivity, organizations can optimize their processes, improve response times, and ultimately drive efficiency in their operations.

Tip: Start by assessing your current DCS infrastructure to identify potential integration points for IoT. Focus on collecting data from sensors and devices already in place, which can provide valuable insights into performance bottlenecks and resource utilization. This foundational step will lay the groundwork for a more interconnected system.

Furthermore, the use of IoT not only aids in operational efficiency but also enhances predictive maintenance capabilities. According to a study by Gartner, IoT-enabled predictive maintenance strategies can lead to a 50% decrease in unscheduled downtime. By integrating smart sensors into your DCS, you can monitor equipment health in real-time, allowing for timely interventions and resource planning.

Tip: Implement a phased approach to IoT integration. Start small with pilot projects focused on critical areas before scaling up. Engaging with stakeholders throughout this process can ensure their buy-in and support, making the transition smoother and more effective.