In today's rapidly evolving industrial landscape, optimizing operational efficiency is paramount for organizations striving to maintain a competitive edge. A paramount tool in achieving this goal is the DCS Control System, which plays a crucial role in the automation of complex processes across various sectors, including manufacturing and utilities. According to a report by MarketsandMarkets, the Distributed Control System market is projected to reach $22.09 billion by 2024, reflecting a compound annual growth rate (CAGR) of 4.9% from 2019. This growth underscores the increasing reliance on advanced control systems to enhance productivity, reduce downtime, and ensure quality output. By leveraging a DCS Control System, industries can streamline their operations, enabling real-time monitoring and control that is essential for maximizing efficiency in a competitive market environment.

In today's rapidly evolving industrial landscape, optimizing operational efficiency is paramount for organizations striving to maintain a competitive edge. A paramount tool in achieving this goal is the DCS Control System, which plays a crucial role in the automation of complex processes across various sectors, including manufacturing and utilities. According to a report by MarketsandMarkets, the Distributed Control System market is projected to reach $22.09 billion by 2024, reflecting a compound annual growth rate (CAGR) of 4.9% from 2019. This growth underscores the increasing reliance on advanced control systems to enhance productivity, reduce downtime, and ensure quality output. By leveraging a DCS Control System, industries can streamline their operations, enabling real-time monitoring and control that is essential for maximizing efficiency in a competitive market environment.

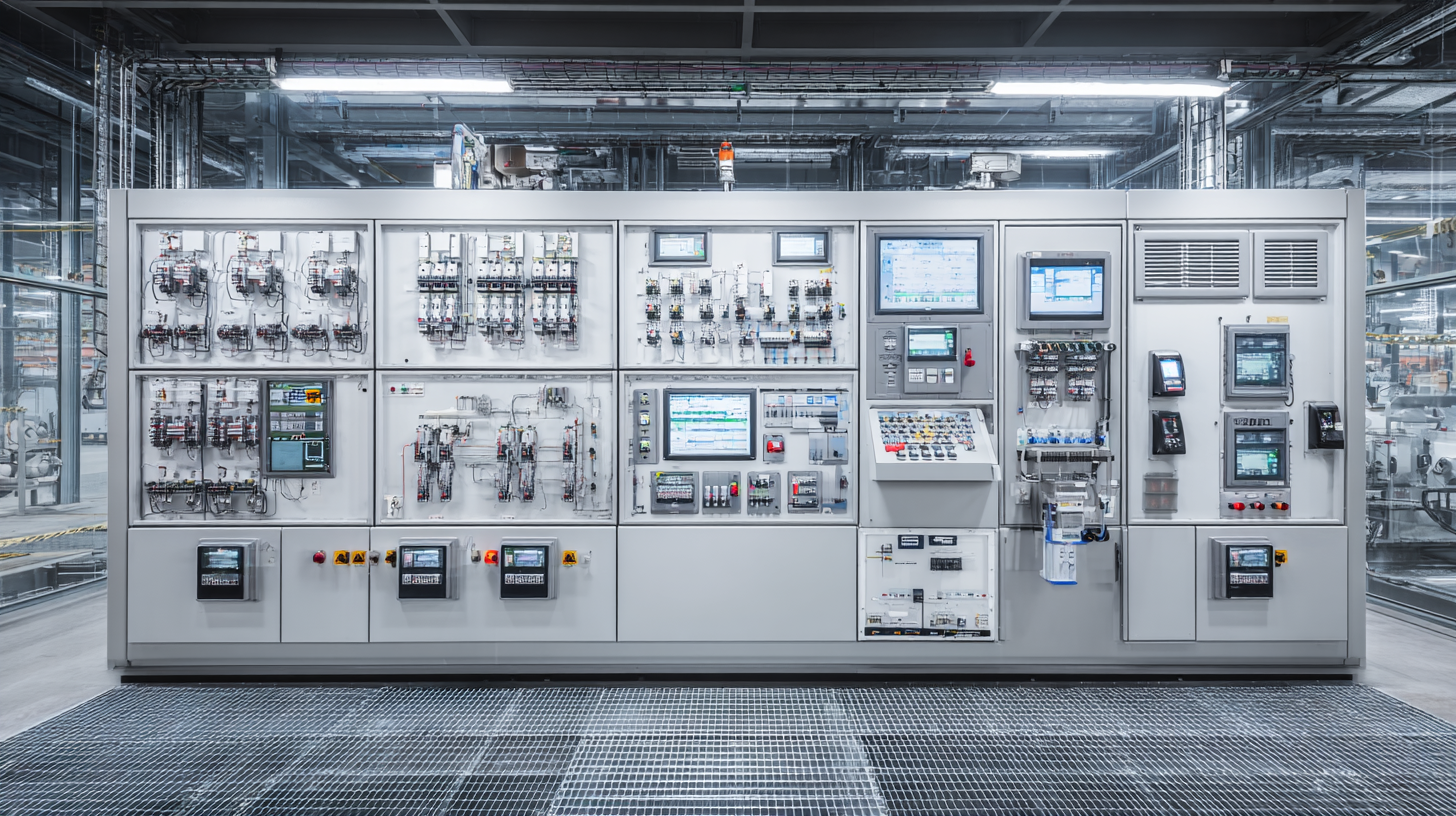

A Distributed Control System (DCS) is an essential framework used in various industries to ensure optimal process control and efficiency. Understanding the basics of DCS is vital for businesses seeking to enhance their operational performance. At its core, a DCS integrates multiple control loops through decentralized control elements, providing accurate monitoring and control over complex processes. This not only boosts productivity but also improves safety and reliability within operations.

Tips for implementing a DCS effectively include conducting thorough system assessments and involving all stakeholders during the planning phase. This ensures that the DCS is tailored to specific operational needs. Additionally, investing in training for staff will facilitate smooth adoption and maximize the system’s benefits.

Regularly updating and maintaining the DCS is also crucial—this includes software updates and hardware checks to prevent potential issues that could disrupt operations or lead to inefficiencies.

Moreover, leveraging data analytics tools alongside the DCS can further enhance its capabilities. By analyzing real-time data, organizations can make informed decisions that optimize processes and reduce waste. These insights allow businesses to proactively manage their operations, resulting in both increased efficiency and profitability.

Identifying key areas for optimization in your operations can significantly enhance efficiency when utilizing a Distributed Control System (DCS). One of the first areas to examine is process automation. By analyzing repetitive tasks and workflows, you can identify opportunities to automate processes, reducing manual intervention and minimizing potential errors. Implementing automated solutions within the DCS can streamline operations and enhance data collection, leading to improved decision-making capabilities.

Another crucial area is real-time data monitoring and analytics. A DCS allows for the continuous monitoring of key performance indicators (KPIs) across various operational facets. By pinpointing inefficiencies or bottlenecks through data analytics, you can concentrate your optimization efforts where they will be most effective. Integrating advanced analytics tools with your DCS can provide insights into equipment performance, energy consumption, and production rates, enabling targeted interventions that drive efficiency gains. Focusing on these areas not only maximizes the advantages of a DCS but also fosters a culture of continuous improvement within your organization.

| Operational Area | Optimization Technique | Expected Efficiency Gain (%) | Implementation Time (Weeks) |

|---|---|---|---|

| Production Scheduling | Automated Scheduling Algorithms | 15% | 4 |

| Quality Control | Real-Time Monitoring | 10% | 3 |

| Energy Management | Load Forecasting | 20% | 5 |

| Maintenance Scheduling | Predictive Maintenance | 25% | 6 |

| Supply Chain Management | Integrated DCS Solutions | 30% | 8 |

Implementing best practices for DCS (Distributed Control System) integration is crucial for optimizing operational efficiency. One of the primary steps in this process is ensuring thorough planning and clear communication among all stakeholders involved. Early involvement of operators, engineers, and IT staff can create a comprehensive understanding of the system requirements and operational goals. This collaborative approach not only helps in identifying potential challenges but also facilitates the seamless integration of the DCS with existing infrastructure.

Additionally, training and support play a significant role in achieving a successful DCS implementation. Providing operators with in-depth training sessions tailored to their specific responsibilities enhances their ability to utilize the system effectively. Continuous support and regular updates help in maintaining system performance and adapting to evolving operational demands. Moreover, establishing clear documentation and protocols for system upgrades and maintenance ensures longevity and reliability of the DCS, ultimately leading to improved efficiency across operations.

In today's rapidly evolving manufacturing landscape, leveraging data analytics within a Distributed Control System (DCS) can significantly enhance operational efficiency. By continuously monitoring and analyzing production data, businesses can identify trends, optimize processes, and make informed decisions that facilitate ongoing improvements. The integration of data analytics enables manufacturers to effectively respond to market demands and streamline operations.

Tips: To maximize the benefits of data analytics, companies should ensure that their DCS is equipped with real-time data processing capabilities. Implementing a feedback loop where data insights inform operational decisions can lead to significant improvements in quality management and supply chain dynamics. Collaborating closely with suppliers also plays a crucial role in creating an agile response mechanism to emerging challenges.

Moreover, fostering a culture of continuous improvement within the organization is essential. Encouraging teams to utilize data insights not only enhances productivity but also innovates product offerings. With artificial intelligence increasingly influencing manufacturing processes, organizations that embrace this technology will likely experience a transformative shift towards smarter operations.

Training your team effectively is essential for maximizing the efficiency of a Distributed Control System (DCS). A well-trained team understands the intricacies of the DCS, which allows them to optimize its capabilities in real-time operations. Facilitating comprehensive training programs that cover the system’s functionalities, troubleshooting techniques, and data analysis can empower your team to make informed decisions quickly. Practical hands-on sessions combined with theoretical knowledge ensure that operators are not just familiar with the technology but can also leverage it to drive operational improvements.

Moreover, fostering a culture of continuous learning is vital. As technology evolves, so should the knowledge of your team. Regular refresher courses and updates on software advancements will keep your operators abreast of the latest features and best practices. Encouraging collaboration and knowledge sharing among team members can also enhance overall competence. When your workforce is equipped with the right skills and knowledge, the DCS will not only function efficiently but also contribute significantly to achieving operational excellence across your organization.