As global supply chains continue to face challenges in complexity and disruption, the integration of Manufacturing Automation has emerged as a crucial solution for enhancing efficiency and resilience. According to a recent report by McKinsey, companies that adopt automation in their manufacturing processes can achieve operational efficiency improvements of up to 30%. Furthermore, the World Economic Forum highlights that automating production not only reduces labor costs but also enables faster response times to market demands, allowing businesses to adapt swiftly to changing consumer preferences.

With advancements in technologies such as AI and IoT, manufacturing automation can drive significant enhancements in accuracy and productivity, ultimately streamlining global supply chains. As industries look towards the future, embracing these automated solutions will be essential for maintaining competitive advantage and ensuring sustained growth in a rapidly evolving market landscape.

Manufacturing automation plays a crucial role in enhancing the efficiency of global supply chains, providing numerous benefits that extend beyond just cost reduction. According to a report by McKinsey & Company, companies that implement advanced automation technologies can increase productivity by up to 25%. This surge in productivity allows manufacturers to meet rising consumer demands with greater agility, ultimately leading to improved customer satisfaction and loyalty.

Moreover, automation reduces the risk of human error, significantly enhancing quality control throughout the supply chain. A study by PwC indicates that 70% of manufacturers experience decreased defects and better compliance with regulations when integrating automation. This quality improvement is essential in global markets, where consistency can determine brand reputation and market share. By reducing defects, manufacturers not only save on costs associated with returns and rework but also enhance their competitive position in an increasingly interconnected world.

In addition to these operational benefits, automation can facilitate real-time data analysis, empowering companies to make informed decisions swiftly. Deloitte reports that organizations leveraging automation and data analytics can optimize their inventory levels, reducing holding costs by as much as 20%. This comprehensive approach to supply chain management — driven by automation — paves the way for more resilient and responsive networks, capable of adapting to market fluctuations and disruptions.

The modernization of global supply chains hinges on key technologies that are revolutionizing manufacturing automation.

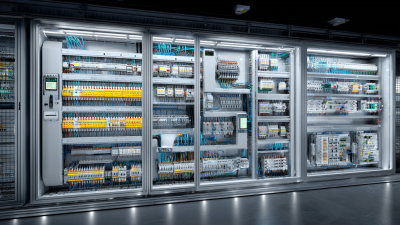

One of the most impactful advancements is the implementation of the Internet of Things (IoT). By connecting machinery and equipment through smart sensors, manufacturers can monitor real-time data, predict maintenance needs, and enhance operational efficiency. This interconnectedness not only streamlines processes but also reduces downtime, ensuring that supply chains remain agile and responsive to market demands.

Another crucial technology driving innovation in supply chain automation is artificial intelligence (AI). AI-powered algorithms analyze vast amounts of data to optimize inventory management, demand forecasting, and production scheduling. This data-driven approach enables manufacturers to react swiftly to fluctuations in demand, cut costs, and minimize waste. Additionally, machine learning techniques can improve decision-making processes over time, leading to better resource allocation and enhanced productivity across the supply chain.

Robotics also play a significant role in the automation landscape, particularly in warehousing and material handling.

Automated guided vehicles (AGVs) and robotic arms are enhancing the speed and accuracy of order fulfillment while reducing labor costs. As these technologies continue to evolve, they promise to transform global supply chains into more efficient, resilient networks capable of meeting the challenges of an ever-changing market.

In the ever-evolving landscape of global supply chains, implementing

automated manufacturing solutions can significantly enhance efficiency and responsiveness.

To begin, companies must conduct a thorough assessment of their current processes to identify areas ripe for automation.

This involves understanding the workflow intricacies and determining which repetitive tasks can be streamlined through automation.

Leveraging technologies such as robotics, AI, and IoT can facilitate smoother operations and minimize human error,

ultimately resulting in cost savings and improved product quality.

Once the needs are identified, developing a strategic roadmap for implementation is critical.

This roadmap should prioritize integration capabilities, ensuring that new automated systems can seamlessly coexist

with existing infrastructure. Training employees to work alongside these technologies is vital

for maximizing their potential. By fostering a culture of adaptability and continuous improvement, organizations can not only optimize

their manufacturing processes but also enhance their overall supply chain resilience. Embracing automation is not merely about technology;

it is about rethinking how businesses operate in a global marketplace.

The implementation of automation in supply chains offers a transformative pathway for manufacturers looking to enhance efficiency and address common logistical challenges. However, obstacles remain prevalent. According to a recent report from the IBM Institute of Business Value, the top five challenges hindering AI adoption in manufacturing include data integration, regulatory concerns, and resistance to change within organizations. Streamlining inventory management through automation can significantly mitigate these issues. For instance, deploying mobile robots and automated systems enables real-time data tracking, which helps overcome issues related to fragmented infrastructure and high logistics costs.

Emerging technologies such as AI, machine learning, and the Internet of Things are not just reshaping manufacturing but are also integral in overcoming the digital transformation hurdles within supply chains. With increasingly sophisticated capabilities, manufacturers can better manage vendor risk and improve contract execution, especially in sectors like biopharma, where outsourcing trends are on the rise due to competitive pressures. By leveraging innovation, manufacturers can create a more adaptable supply chain, reducing reliance on traditional practices and ultimately driving greater strategic efficiency.

The success of automated supply chain processes can be quantitatively assessed through various key performance indicators (KPIs). According to a report by McKinsey, companies that have adopted automation in their supply chains have seen productivity gains of up to 30%. This significant improvement not only accelerates manufacturing cycles but also reduces operational costs, providing a clear advantage in today's competitive global market. By continuously measuring metrics such as lead time, inventory turnover, and order accuracy, businesses can evaluate the effectiveness of their automated systems and make informed adjustments.

To ensure optimal performance in automated supply chain operations, companies should consider implementing a robust data analytics framework. This framework can facilitate real-time monitoring and generate insights that drive decision-making. As highlighted by a study from Deloitte, organizations that leverage advanced analytics can reduce their logistics costs by as much as 15%.

**Tip 1:** Regularly review automated processes and align KPIs with overall business objectives to ensure that automation efforts are contributing to broader goals.

**Tip 2:** Invest in employee training to equip staff with the necessary skills to work alongside automated systems, fostering a culture of innovation and adaptability.