Industrial Control Systems (ICS) play a pivotal role in managing critical infrastructures across various sectors, including energy, manufacturing, and transportation. However, as dependence on these systems increases, so do the vulnerabilities they face. According to the Cybersecurity and Infrastructure Security Agency (CISA), over 70% of organizations experience cyberattacks targeting their ICS, highlighting a pressing need for robust mitigation strategies. As cybersecurity becomes an integral focus, understanding the potential threats to ICS is essential for safeguarding operational integrity and ensuring public safety.

Renowned cybersecurity expert Dr. Emily Chen emphasizes the urgency of addressing these threats: "In today’s interconnected environment, the resilience of Industrial Control Systems is non-negotiable. The future of our critical infrastructure depends on our ability to proactively mitigate risks." This statement underscores the necessity of vigilance in the face of evolving cyber threats that pose significant risks to operational continuity. By identifying the top threats to ICS and implementing effective mitigation strategies, organizations can enhance their cyber defenses while ensuring the stability and reliability of essential services. As we delve into the top ten threats to Industrial Control Systems and methodologies for their mitigation, it is imperative for stakeholders to adopt a proactive and comprehensive approach to cybersecurity.

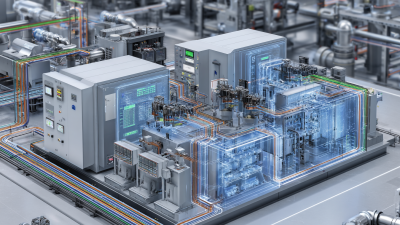

Industrial Control Systems (ICS) play a crucial role in managing and controlling industrial operations across various sectors, including manufacturing, energy, and transportation. These systems encompass a range of control components, such as supervisory control and data acquisition (SCADA) systems, distributed control systems (DCS), and programmable logic controllers (PLC). According to a recent report by the International Society of Automation, approximately 60% of critical infrastructure organizations have experienced at least one cyber incident targeting their ICS within the last decade, highlighting the urgency for robust security measures.

The importance of ICS cannot be overstated; they ensure operational efficiency, reliability, and safety in industrial processes. For instance, in the energy sector, ICS are integral to maintaining the stability of power grids, with the U.S. Department of Energy estimating that over 70% of the country's electrical grid is managed via these systems. With the increasing interconnectivity of networks and the rise of IoT devices, the attack surface for potential threats has expanded significantly. A report from Cybersecurity and Infrastructure Security Agency (CISA) indicates that malicious cyberattacks on ICS could lead to catastrophic failures, endangering public safety and disrupting essential services. Therefore, understanding the risks associated with ICS and implementing effective mitigation strategies are critical for safeguarding vital infrastructure.

Industrial Control Systems (ICS) are vital for managing and automating processes in various industries such as manufacturing, energy, and water treatment. However, these systems are increasingly becoming targets for cyber threats, which can lead to severe disruptions and safety risks. Identifying the top threats to ICS is essential for implementing effective security measures. Some of the most pressing threats include malware attacks, unauthorized access, insider threats, and supply chain vulnerabilities. Each of these threats can disrupt operations, compromise data integrity, and even endanger public safety.

To mitigate these risks, organizations should adopt a multi-layered security approach. Regular security assessments can help identify potential vulnerabilities in the system. Implementing strict access controls ensures that only authorized personnel can access critical systems. Additionally, training employees on cybersecurity best practices and promoting a culture of security awareness can help prevent insider threats. Finally, collaborating with trusted partners in the supply chain and conducting regular updates on software and hardware can minimize vulnerabilities. By prioritizing these strategies, organizations can better protect their ICS against the evolving landscape of cyber threats.

Industrial control systems (ICS) are integral to the operation of various sectors, including manufacturing, energy, and transportation. However, cybersecurity breaches pose significant risks, potentially disrupting operations, ruining product quality, and even endangering lives. Analyzing the impact of these breaches reveals that vulnerabilities in ICS can lead to unauthorized access, resulting in catastrophic failures that affect not only the affected facility but also the broader supply chain and economic stability.

To mitigate these risks, it is vital to implement robust cybersecurity measures. Start by conducting a comprehensive risk assessment to identify potential vulnerabilities within your ICS environment. Regularly update your security protocols and ensure that all software and hardware are patched against known vulnerabilities.

Tips: Establish an incident response plan that enables swift action in the event of a breach. Training employees on cybersecurity awareness can also strengthen your defenses, as human error is often the weakest link. Continuously monitor your systems for suspicious activity to detect potential threats before they escalate into serious incidents.

Industrial Control Systems (ICS) are critical components in various sectors, including manufacturing, energy, and utilities. With the rise of cyber threats, protecting these systems has become paramount. According to the 2022 Verizon Data Breach Investigations Report, 42% of breaches involved targeted attacks against operational technology (OT) environments. To mitigate these threats, organizations must implement a multi-layered security approach that combines technology and best practices.

One effective strategy is to deploy network segmentation, which isolates ICS from corporate networks. This not only reduces the attack surface but also limits the lateral movement of potential intruders. Additionally, regular cybersecurity assessments and penetration testing can help identify vulnerabilities within the system. The SANS Institute highlights that 91% of successful data breaches are attributed to human error; thus, incorporating comprehensive training programs for employees is essential to foster a security-conscious culture.

Furthermore, adopting advanced monitoring solutions powered by artificial intelligence can enhance threat detection and response capabilities. The 2023 Global Industrial Cybersecurity Report indicates that organizations employing AI-driven security measures experienced a 30% decrease in incident response time. By continuously analyzing network traffic and flagging anomalous behavior, these tools enable ICS operators to act swiftly in the face of emerging threats, thereby safeguarding critical infrastructure and ensuring operational continuity.

This chart illustrates the top 10 threats to industrial control systems, ranked by their risk level on a scale of 1 to 10. Each threat represents a significant concern for organizations relying on industrial automation and control, highlighting the importance of robust security measures to mitigate these risks.

Continuous monitoring and incident response are crucial for safeguarding industrial control systems (ICS) against an ever-evolving threat landscape. Organizations must implement best practices that enable real-time visibility into their systems, allowing for prompt detection of anomalies and potential attacks. By utilizing advanced monitoring tools, businesses can track network traffic, identify unauthorized access, and respond swiftly to any security incidents.

Tips for effective continuous monitoring include establishing a baseline of normal activity. Understanding usual patterns enables teams to better identify deviations that could signify a potential threat. Additionally, incorporating automated alert systems can ensure that security teams are notified immediately of suspicious behavior, minimizing response times and limiting potential damage.

Incident response is equally important as it ensures that organizations can react effectively when a security breach occurs. Establishing a clear incident response plan is essential, detailing roles, responsibilities, and communication protocols during an emergency. Regular drills and updates to the plan based on lessons learned from previous incidents further strengthen an organization’s preparedness, fostering resilience against disruptions.

| Threat | Description | Mitigation Strategy |

|---|---|---|

| Malware | Malicious software designed to disrupt or gain unauthorized access to systems. | Use antivirus solutions and conduct regular system scans. |

| Phishing | Fraudulent attempts to obtain sensitive information by disguising as a trustworthy entity. | Conduct awareness training and simulate phishing attacks. |

| Insider Threats | Employees or contractors misusing their access to company systems. | Implement strict access controls and conduct background checks. |

| Ransomware | Malware that encrypts data and demands ransom for decryption. | Regularly back up data and maintain offline backups. |

| Denial-of-Service (DoS) | Attacks that aim to make systems unavailable by overwhelming them with traffic. | Implement network traffic analysis and filtering tools. |

| Unpatched Vulnerabilities | Exploiting known vulnerabilities in outdated software. | Regularly update and patch all software and systems. |

| Poor Configuration | Improperly configured systems that can lead to security gaps. | Conduct regular security audits and configuration reviews. |

| Supply Chain Attacks | Attacks that target the security vulnerabilities of third-party vendors. | Perform due diligence and assess third-party security practices. |

| Inadequate Incident Response | Lack of a structured approach to manage and mitigate security incidents. | Develop and regularly update an incident response plan. |