In the world of automation, the Dcs System stands out as a critical component in various industries. According to Dr. Emily Johnson, a leading expert in automation technologies, "The Dcs System is vital for achieving efficiency and control in complex industrial processes." Understanding these systems can enhance operations and reduce costs.

Dcs Systems enable seamless communication between various components in an industrial setup. They integrate data from sensors and process units, providing real-time feedback. Yet, many organizations face challenges in implementation. Not all Dcs Systems are user-friendly, leading to potential mismanagement and errors.

Furthermore, the rapid pace of technological advancement means that some legacy systems may become obsolete. Companies must reflect on their current Dcs System strategies to ensure they remain competitive. This discussion highlights the key aspects of Dcs Systems that every professional should grasp.

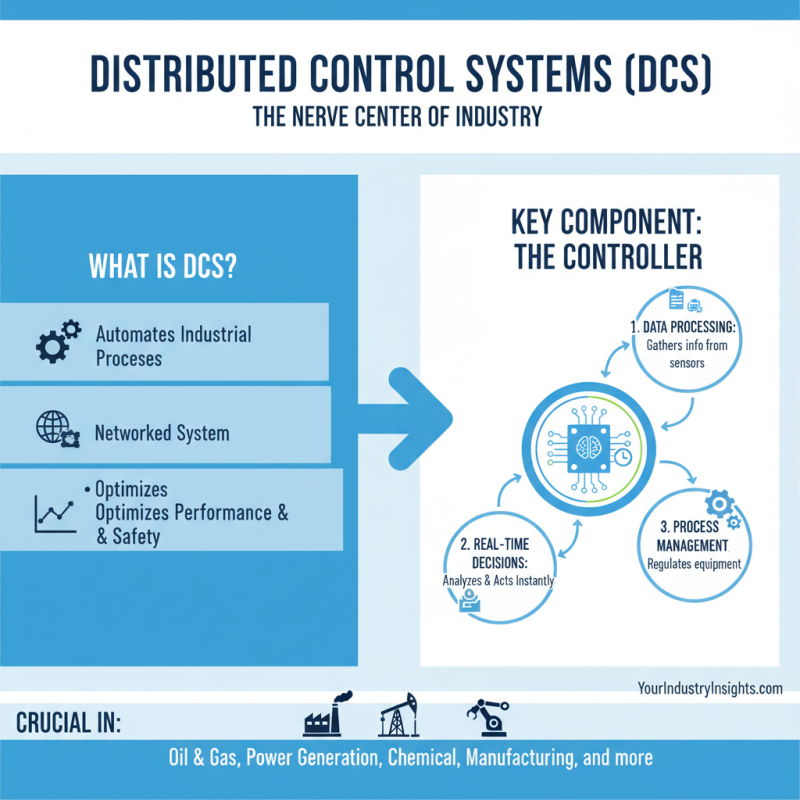

A Distributed Control System (DCS) serves a crucial role in industrial automation. It integrates various components to control processes in real-time. The main purpose is to enhance efficiency and safety. With a DCS, operators can monitor numerous variables simultaneously. This system supports complex processes, like chemical manufacturing and power generation.

Understanding the definition of a DCS is essential. It comprises hardware and software that connect different parts of a facility. Each component communicates and collaborates to achieve operational goals. Feedback loops allow for adjustments, ensuring optimal performance. However, it's important to note that not all systems are foolproof. Users must be vigilant about potential failures. Redundancies can help but may not cover every scenario.

Choosing the right system is vital, but challenging. Each facility has unique needs and goals. Operators must assess what features are necessary. A mismatch can lead to inefficiencies or safety risks. Continuous training and adaptation are necessary. The use of a DCS is both rewarding and demanding. Understanding its purpose helps in maximizing benefits while acknowledging limitations.

| # | Aspect | Description |

|---|---|---|

| 1 | Definition | A Distributed Control System (DCS) is a control system that uses a network of controllers to manage complex processes. |

| 2 | Purpose | To facilitate automated control and monitoring of processes across various industries. |

| 3 | Components | Typically includes controllers, sensors, actuators, and a user interface. |

| 4 | Benefits | Improved efficiency, reduced operating costs, enhanced safety, and increased flexibility. |

| 5 | Applications | Widely used in industries such as oil and gas, chemical processing, power generation, and water treatment. |

| 6 | Architecture | Includes a hierarchical structure with field devices, controllers, and operator stations. |

| 7 | Communication | Utilizes protocols like Ethernet, Fieldbus, and proprietary systems for data exchange. |

| 8 | User Interface | Typically features graphical representation of processes and alarm management tools. |

| 9 | Best Practices | Regular maintenance, training, and updates to software are crucial for optimal performance. |

| 10 | Future Trends | Increased implementation of AI, IoT integration, and enhanced data analytics capabilities. |

Distributed Control Systems (DCS) play a crucial role in various industries. Understanding their key components is essential. At the heart of a DCS are controllers. These devices manage processes and ensure optimal performance. They process data and make real-time decisions.

Another critical element is the human-machine interface (HMI). This interface allows operators to interact with the system. It displays data visually, enabling quick decision-making. An effective HMI is user-friendly but can sometimes be overwhelming with too much information.

Finally, communication networks link components together. They transfer data between controllers, sensors, and HMIs. A reliable network is vital for the system’s success. However, not all networks are built equally. Latency issues can hinder performance. Reflecting on these aspects can lead to better implementation strategies.

DCS systems play a crucial role in enhancing industrial automation. These systems centralize control, improving efficiency and reliability. According to a report by the International Society of Automation, implementing DCS can lead to a 30% reduction in operational costs. This is significant for industries like oil and gas, where margins are tight.

Automation ensures that processes run smoothly. DCS systems monitor various parameters in real time, minimizing human error. A study found that 60% of industrial incidents stem from operator mistakes. By automating repetitive tasks, these systems help mitigate risks. However, reliance on automated processes can lead to complacency among operators, necessitating ongoing training.

Data flow between components is vital. DCS systems enable seamless communication, which boosts productivity. Some industries report productivity increases of up to 25% post-DCS implementation. Yet, integration can be challenging. Legacy systems may resist seamless upgrades, causing potential downtime. Regular assessments are key to optimizing these systems effectively.

Implementing a Distributed Control System (DCS) in manufacturing can transform processes. A DCS enhances automation, offering real-time data management. Manufacturers report up to a 30% increase in operational efficiency. With improved data visibility, operators can make quicker decisions. This results in reduced downtime and significant cost savings.

Integration of a DCS can reduce incident rates by over 20%. Precision monitoring leads to fewer errors. For instance, in chemical manufacturing, even slight deviations can be costly. However, a DCS allows for tighter control over processes. It helps in adhering to safety protocols better. The implementation costs can be high, but the return on investment is often realized within a few years.

Challenges exist. Some operators may resist changes in workflow. Training becomes essential to maximize the DCS potential. Not all systems offer the same level of compatibility with existing machinery. It's crucial to conduct thorough assessments before implementation. Yet, the industry trend indicates a shift towards smarter, more integrated systems. Overall, the benefits of a DCS are hard to overlook.

The future of Distributed Control Systems (DCS) is vibrant and dynamic. Emerging technologies are reshaping traditional operations. One notable trend is the integration of artificial intelligence. AI can analyze data in real-time. It enhances decision-making processes and predicts equipment failures. Imagine machines that learn from past data. They become more efficient over time.

Another innovation is the use of the Internet of Things (IoT). Sensors will collect vast amounts of data. This data can be monitored remotely. It enables proactive maintenance and quick responses to issues. However, reliance on technology may create vulnerabilities. Cybersecurity becomes a significant concern for operations.

Cloud computing also plays a pivotal role. It allows for better data storage and accessibility. Operators can access critical information from anywhere. Nevertheless, not all systems adapt well to cloud solutions. A balance between cloud and local systems is essential. As we move forward, continuous reflection on these technologies will help enhance system reliability.

This chart illustrates the key features and trends in Distributed Control Systems (DCS) technology. The data includes various attributes related to system performance, user adoption, and innovation trends over recent years.