In the ever-evolving landscape of industrial automation, the DCS Control System has emerged as a cornerstone technology that significantly enhances operational efficiency across numerous sectors. According to a report by MarketsandMarkets, the global Distributed Control System market is projected to reach USD 26.69 billion by 2026, growing at a CAGR of 6.7% from 2021. This growth reflects the increasing adoption of automation systems aimed at optimizing production processes, ensuring safety, and improving product quality.

The DCS Control System plays a pivotal role in integrating complex processes, enabling real-time data analytics and decision-making capabilities that streamline operations. Industries such as oil and gas, chemicals, and power generation are witnessing substantial transformations, as the DCS facilitates greater control and monitoring of plant operations. Moreover, a report by ResearchAndMarkets highlights that the efficiency gained through DCS implementation can lead to a reduction in operational costs by up to 30%, showcasing its key role in driving profitability and sustainability in modern manufacturing environments.

As companies continue to embrace Industry 4.0 principles, the DCS Control System will undoubtedly remain integral in not only improving efficiency but also fostering innovation and adaptability within industrial settings. This introduction sets the stage for an in-depth exploration of how DCS technology is revolutionizing industrial processes, ensuring a competitive edge in today's dynamic marketplace.

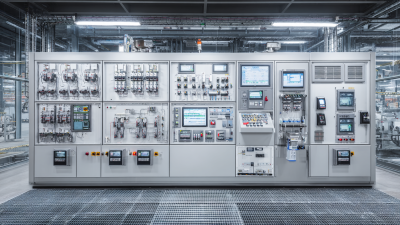

Distributed Control Systems (DCS) have significantly transformed industrial automation by providing a more robust and efficient way to monitor and control complex processes. One of the primary advantages of DCS is its ability to improve operational efficiency through real-time data processing. This allows for quicker decision-making and helps in minimizing downtime, as operators can respond to anomalies instantly. Enhanced data visualization and reporting capabilities further enable industries to optimize processes and predict maintenance needs, thus reducing operational costs.

**Tip:** When integrating a DCS into your operation, ensure that you involve all relevant stakeholders in the planning phase. Understanding their unique needs and insights can lead to better implementation strategies and increased acceptance across the board.

Another notable benefit of DCS is its scalability. As a business grows, its operational needs evolve, and a DCS can be expanded to accommodate these changes without significant overhauls. This flexibility ensures that companies can invest in the system without the fear of obsolescence, making DCS an economically sound choice for long-term automation strategies.

**Tip:** Regularly assess your DCS performance and adapt its configurations to meet changing production requirements. This proactive approach can keep your operational efficiency at its peak.

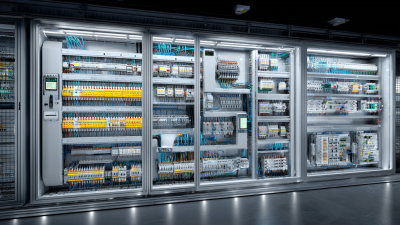

Distributed Control Systems (DCS) play a critical role in optimizing industrial processes, enhancing efficiency across various sectors, including agriculture, manufacturing, and energy management. Key components of DCS, such as sensors, controllers, and human-machine interfaces, ensure real-time monitoring and control, enabling operators to make informed decisions that improve productivity and resource management. For example, adaptive control systems utilizing machine learning algorithms provide robust solutions for applications like intelligent irrigation, ensuring optimal water usage and reducing waste in agricultural practices.

Moreover, the implementation of standards, like the ISA-5 series, facilitates effective integration of instruments and control systems, which is essential for complex industrial environments. This standardization allows for better interoperability and reliability, particularly in sectors where water quality and supply are critical, such as in municipal and industrial applications. Enhanced interconnectivity between components further supports advanced functionalities, like digital twins, that simulate real-world processes and conditions, leading to smarter and more efficient operations throughout the industry.

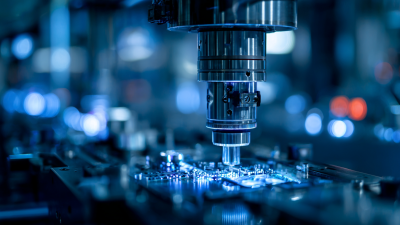

The integration of Distributed Control Systems (DCS) with the Internet of Things (IoT) marks a significant advancement in the quest for enhanced operational efficiency in industrial automation. By leveraging IoT technology, DCS can collect and analyze real-time data from various sensors and devices throughout the production environment. This connectivity facilitates a level of monitoring and control that was previously unattainable, allowing for rapid detection of anomalies and predictive maintenance capabilities. As a result, organizations can optimally adjust their processes, reduce downtime, and minimize resource waste.

Moreover, the synergy between DCS and IoT fosters a more agile manufacturing ecosystem. With the implementation of IoT-driven analytics, industrial operators can make informed decisions based on comprehensive insights gathered from multiple data points. This interconnected framework streamlines communication between different systems, leading to better coordination and responsiveness in production operations. Ultimately, the integration not only enhances efficiency but also enables industries to adapt swiftly to changing market demands, ensuring long-term sustainability and competitiveness in the global marketplace.

The implementation of Distributed Control Systems (DCS) in various industries stands at a pivotal juncture as organizations face the dual challenges of enhancing efficiency while also addressing sustainability concerns. Recent assessments highlight the need for advanced digital infrastructures that not only optimize operational workflows but also contribute to environmental goals. For instance, papers focusing on the decarbonization of urban digital infrastructures, particularly in data centres, reveal the intricate balance that must be maintained between digitization and sustainability. Companies are now seeking solutions that enable them to meet regulatory frameworks while adopting energy-efficient technologies, which is crucial in industries like shipping, where carbon intensity indicators play a significant role.

Moreover, the rise of artificial intelligence within DCS frameworks indicates a shift towards more autonomous production processes. With over 85% of major corporations leveraging AI technologies, these systems offer actionable insights that allow organizations to proactively manage their operations. The integration of Industrial Internet of Things (IIoT) technologies further enhances this landscape, promising to tackle challenges through improved data handling practices. As industries navigate these complexities, the synergy between DCS, AI, and IoT not only promises operational resilience but also supports broader environmental initiatives, marking a significant transformation in industrial automation.

As industries continue to evolve, Distributed Control Systems (DCS) are at the forefront of transforming automation strategies. Future trends indicate that the integration of artificial intelligence and machine learning with DCS technology will bring unprecedented efficiency and real-time decision-making capabilities. This fusion will enable organizations to optimize their processes, reduce downtime, and enhance overall productivity.

Tip: Companies should consider investing in training programs for their workforce to leverage these advanced technologies effectively. By upskilling employees, organizations can ensure that they fully harness the potential of AI-enhanced DCS platforms.

Moreover, the shift towards cloud-based DCS solutions is set to revolutionize data accessibility and analysis. These solutions will enable remote monitoring and control, making it easier for operators to manage systems from anywhere in the world. The increased connectivity will also foster better collaboration between teams, leading to more cohesive and responsive operational strategies.

Tip: Implementing a phased transition to cloud-based systems can help mitigate risks. Start with a pilot project to assess performance and gather insights before a full-scale rollout. This approach allows for adjustments based on initial learnings, ensuring a smoother evolution to next-gen automation.