In the dynamic landscape of modern automation, the pivotal role of programmable logic controllers (PLCs) has become increasingly evident, with Schneider PLC emerging as a frontrunner in this domain. According to a recent report by Research and Markets, the global PLC market is projected to reach $22 billion by 2026, demonstrating a compound annual growth rate (CAGR) of 7.2%. This surge highlights the growing demand for innovative automation solutions across various industries, from manufacturing to energy management. Schneider PLC is at the forefront of this evolution, offering unique applications that enhance operational efficiency, improve scalability, and facilitate seamless integration with IoT technologies.

As industries strive to embrace digital transformation, the versatility and advanced features of Schneider PLC are set to pave the way for revolutionary automation strategies, underscoring its importance in driving sustainable and intelligent manufacturing systems.

The global industrial automation market is anticipated to reach a staggering $403.08 billion by 2033, expanding from $134.6 billion in 2024, driven by a compound annual growth rate (CAGR) of 8.5%. This rapid growth underscores the critical role that programmable logic controllers (PLCs) play in modern automation solutions. Schneider PLCs serve as a catalyst for this innovation, providing robust and flexible control solutions that empower industries to enhance productivity and operational efficiency in a rapidly evolving technological landscape.

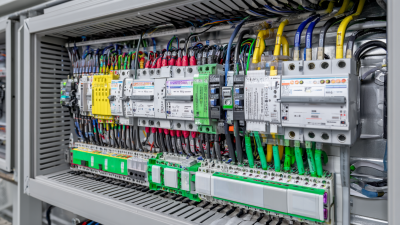

The rise of the commercial automation sector positions PLCs at the forefront of industrial advancements. With an increasing demand for streamlined processes and real-time data integration, Schneider PLCs offer unique applications that cater to diverse sectors, from manufacturing to logistics. The flexibility of these controllers enables businesses to adapt swiftly to market changes, thereby fostering an environment conducive to innovation and growth. This transformative potential illustrates how integrated automation solutions are not just a trend but a foundation for future industrial success.

| Application Area | Description | Benefits | Automation Level |

|---|---|---|---|

| Manufacturing | Integration of robotic systems for assembly line efficiency. | Increased throughput and reduced manual errors. | Full Automation |

| Process Control | Real-time monitoring and control of process variables. | Enhanced process reliability and safety. | Semi-Automation |

| Building Automation | Smart building management systems for energy efficiency. | Reduced energy costs and improved occupant comfort. | Full Automation |

| Water Treatment | Automated control of water quality and supply processes. | Improved resource management and compliance. | Full Automation |

| Logistics | Automated warehousing and inventory management systems. | Increased accuracy in order fulfillment and tracking. | Full Automation |

The industrial automation landscape is rapidly evolving, with innovative solutions driving efficiency and productivity. The adoption of Programmable Logic Controllers (PLCs) has become pivotal in this transformation. A recent report indicates that the PLC software market is projected to reach USD 13.99 billion by 2025, expanding at a compound annual growth rate (CAGR) of 11.08% through 2033. This growth is indicative of an increasing demand for intelligent automation solutions that enhance operational flexibility and resource management.

Schneider Electric's introduction of the EcoStruxure open automation platform exemplifies the shift towards integrated, scalable systems that facilitate seamless connectivity across devices and platforms. By aligning with the UAO Open Automation Organization, Schneider is positioning itself as a leader in redefining operational standards within the industry. This innovative approach not only supports diverse applications of PLCs but also fosters an environment conducive to smart manufacturing, industrial Internet of Things (IIoT), and advanced robotics. As industrial processes continue to incorporate more sophisticated control systems, the role of PLCs and their unique applications in this modern landscape will be vital for achieving competitive advantages.

In the realm of modern automation, Schneider PLC stands out not only for its robust performance but also for its innovative applications across various industries. When comparing Schneider PLC with alternative control systems, several key factors come into play. One major advantage of Schneider PLCs is their versatility; they can seamlessly integrate with a wide range of devices and technologies, making them ideal for complex automation tasks. Their user-friendly programming environment simplifies the development process, enabling engineers to implement solutions swiftly and efficiently.

On the other hand, alternative control systems, such as Siemens or Rockwell, may offer specialized features that could cater to certain applications better than Schneider. For instance, Siemens PLCs are often lauded for their superior connectivity options, allowing for more extensive networking capabilities in large installations. However, Schneider excels in terms of support and community resources, with a wealth of documentation and user forums that facilitate troubleshooting and knowledge sharing. Ultimately, the choice between Schneider PLC and its alternatives hinges on specific project requirements, budget considerations, and the desired level of support, proving that in automation, there's no one-size-fits-all solution.

In today's rapidly evolving landscape,

Schneider PLCs are transforming industries through innovative applications that showcase their adaptability and efficiency.

For instance, in the manufacturing sector, companies are incorporating Schneider PLCs to automate complex production lines,

leading to increased precision and reduced downtime. A notable success story comes from a major automotive manufacturer

that utilized Schneider PLCs to streamline its assembly process, resulting in a 30% increase in throughput while minimizing errors.

To harness the full potential of Schneider PLCs in your operations, consider the following tips.

First, invest in training for your team to maximize the capabilities of these systems;

a well-informed workforce can significantly impact productivity.

Second, continually assess and upgrade your automation strategies to stay ahead of market demands.

Maintaining an agile approach allows you to adapt and innovate in real-time,

leveraging the full range of functionalities that Schneider PLCs offer.

In the food and beverage industry, manufacturers have also seen remarkable results.

For example, a leading company integrated Schneider PLCs to enhance its packaging processes,

which reduced waste and improved product quality.

Such real-world applications illustrate the profound impact that Schneider PLCs can have across various sectors,

driving efficiency and innovation.

The landscape of automation is rapidly evolving, and Schneider PLC is at the forefront of this transformation. As industries strive for smarter operations and greater efficiency, the integration of Schneider PLCs into next-gen automation technologies has become increasingly critical. These programmable logic controllers are designed not only to streamline existing processes but also to facilitate innovation in applications such as IoT connectivity, advanced data analytics, and machine learning.

The landscape of automation is rapidly evolving, and Schneider PLC is at the forefront of this transformation. As industries strive for smarter operations and greater efficiency, the integration of Schneider PLCs into next-gen automation technologies has become increasingly critical. These programmable logic controllers are designed not only to streamline existing processes but also to facilitate innovation in applications such as IoT connectivity, advanced data analytics, and machine learning.

One of the most compelling future trends is the convergence of automation with artificial intelligence, where Schneider PLCs can serve as the backbone for intelligent manufacturing systems. By leveraging AI, these PLCs can enhance predictive maintenance, optimize production processes, and enable real-time decision-making. Furthermore, as the demand for sustainable practices rises, Schneider PLCs are being adapted to improve energy management and reduce waste, ensuring that businesses remain compliant with environmental standards while enhancing operational efficiency.

With their robust architecture and flexibility, Schneider PLCs are paving the way for smart factories of the future, enabling seamless integration with other technologies such as cloud computing and edge devices. This integration will empower manufacturers to harness the full potential of Industry 4.0, driving unprecedented levels of productivity and innovation across the board. The journey towards next-gen automation is just beginning, and Schneider PLC is leading the charge.