The evolution of manufacturing has been significantly shaped by advancements in Automation Parts, enabling industries to enhance efficiency, productivity, and safety. As noted in the 2022 World Automation Report, companies that integrated automation technologies into their operations saw a remarkable 30% increase in production efficiency and a 25% reduction in operational costs. This trend is increasingly driven by the demand for customized production solutions and sustainable practices in an age where consumers expect rapid delivery and high-quality products. With emerging technologies such as AI and IoT, the landscape of automation is constantly changing, leading to the development of unique features and applications of Automation Parts. This blog aims to explore these innovations and provide insights into the best alternatives available, ensuring that businesses remain competitive in an ever-evolving market.

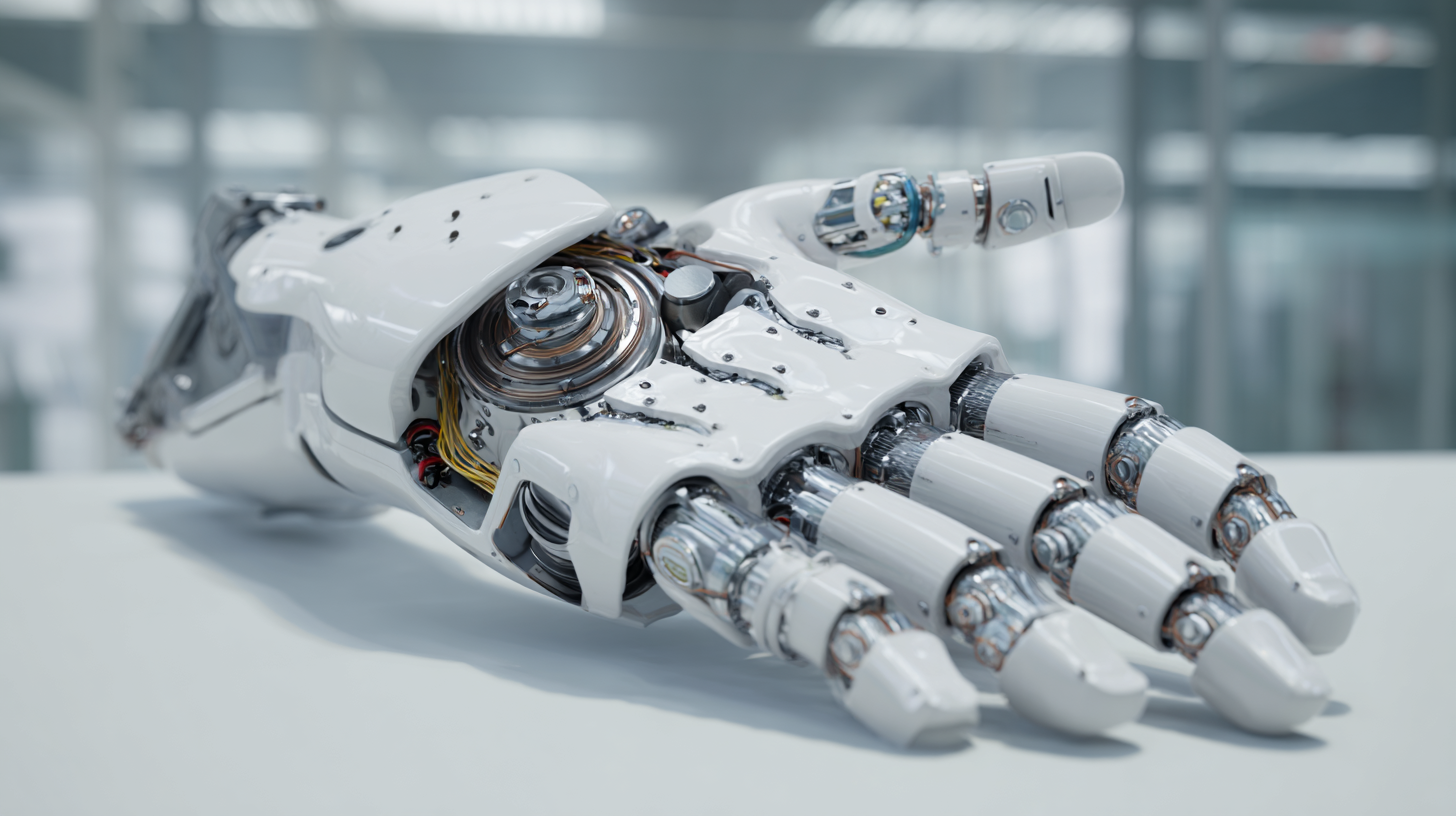

In modern industries, automation parts play a crucial role in enhancing efficiency and productivity. Understanding the essential components of these automation systems is vital for businesses seeking to innovate and streamline their operations. Key elements such as sensors, actuators, and controllers serve as the foundational building blocks, enabling machines to perform complex tasks with speed and precision.

Sensors gather real-time data from the environment, while actuators convert electrical signals into mechanical movement, and controllers manage and coordinate these processes to ensure seamless functionality.

Sensors gather real-time data from the environment, while actuators convert electrical signals into mechanical movement, and controllers manage and coordinate these processes to ensure seamless functionality.

Moreover, the evolution of automation parts has opened up a plethora of applications across various sectors, including manufacturing, logistics, and healthcare. With advancements in technology, industries are now able to implement smarter systems that can adapt and learn from their operating environments. This shift not only reduces the margin for error but also minimizes operational costs, thereby enhancing overall productivity. Exploring alternatives to traditional automation components also allows companies to customize solutions that fit their specific requirements, fostering innovation and competitiveness in an ever-evolving market.

Automation parts are transforming various sectors by enhancing efficiency and productivity through innovative applications. In manufacturing, for instance, automated assembly lines equipped with robotics and sensors streamline production processes, allowing companies to meet demand with precision and speed. These systems not only reduce labor costs but also minimize the risk of human error, resulting in higher-quality products.

In the agricultural sector, the use of automated drones and sensors is revolutionizing farming practices. Precision agriculture leverages these technologies to monitor crop health, optimize irrigation, and manage resources effectively. By employing automated systems, farmers can make data-driven decisions that lead to better yields and sustainable practices, showcasing how automation can address contemporary challenges in food production.

The healthcare industry is also benefiting from automation parts, particularly in areas such as patient monitoring and robotic surgery. Automated systems facilitate real-time data collection and analysis, allowing for timely interventions and improved patient outcomes. Furthermore, robotic surgeries enhance precision and reduce recovery times, illustrating the critical role of automation in advancing medical practices. Each of these examples highlights the versatile applications of automation parts across diverse domains, paving the way for continued innovation and efficiency.

In the rapidly evolving landscape of automation parts, it is essential to conduct a comparative analysis between leading components and emerging alternatives. As smart measurement and control equipment manufacturing becomes a vital subset of the intelligent manufacturing sector, the demand for innovative automation solutions continues to rise. Recent investments, particularly in semiconductor equipment development, reflect a growing trend towards domestic innovation and independence in critical components.

One key trend is the increasing adoption of remanufactured automotive parts, projected to reach a market value of approximately $3.37 billion by 2032. This trend highlights the importance of sustainability and cost-effectiveness in automation solutions. Emerging alternatives often boast lower costs while providing comparable performance, making them attractive options for businesses looking to optimize their operations without sacrificing quality.

To navigate this landscape effectively, consider these tips:

When selecting automation parts for your project, it’s essential to consider several key factors that can significantly influence both performance and efficiency. According to a report by Grand View Research, the global industrial automation market is expected to reach $296.70 billion by 2028, indicating a robust demand for precision and reliability in automation components. This growth suggests that choosing the right automation parts is crucial for ensuring that your operations can scale efficiently while maintaining optimal performance.

One of the primary considerations should be compatibility with existing systems. For instance, an automation part that integrates seamlessly with your current technology can reduce downtime and improve overall productivity. Additionally, the quality of the parts is vital; a survey conducted by MarketsandMarkets revealed that 32% of manufacturers reported issues arising from subpar automation components, which often led to increased operational costs. Lastly, evaluate the supplier's reputation and support services, as ongoing technical assistance can be invaluable, especially for complex projects. Prioritizing these factors ensures that you choose automation parts that will not only meet current needs but also adapt to future demands.

| Automation Part | Unique Features | Common Applications | Key Factors to Consider |

|---|---|---|---|

| Sensors | High sensitivity, fast response times | Temperature monitoring, motion detection | Accuracy, environment suitability |

| Actuators | Variety of power sources, precise control | Robotics, assembly lines | Torque requirements, speed control |

| Controllers | Programmable, user-friendly interfaces | Manufacturing processes, smart homes | Compatibility, scalability |

| Conveyors | Modular design, adjustable speeds | Material handling, warehouse automation | Load capacity, footprint |

| Valves | Quick response, diverse operation modes | Fluid control, HVAC systems | Pressure ratings, ease of maintenance |

As we look toward the next decade, the automation parts industry is set to undergo significant transformations driven by advancements in technology and evolving market demands. The future of PLC (Programmable Logic Controller) systems appears promising with trends focusing on autonomy, network connectivity, intelligence, and enhanced information security. These developments are not just about improving operational efficiency; they are also oriented towards creating safer and more reliable automated environments.

The growth of humanoid robots indicates a strong potential in the market for critical components such as harmonic reducers, motors, and sensors. As major players continue to innovate and enter the sector, the profitability of these components will likely increase, accelerating the evolution of automation technologies. Additionally, the vacuum automatic heat treatment furnace market is projected to expand, reflecting a broader trend in automation where efficiency and precision are paramount. As these components become more sophisticated, industries across the board can expect to embrace automation solutions that are smarter and more integrated than ever before.